Deviation adjusting device and deviation adjusting method for insulating sheath mold

An insulating sheath and mold technology, which is applied in the field of insulating sheath mold deviation adjustment devices, can solve the problems of low efficiency of artificial hollow deviation adjustment, and achieve the effects of saving manpower and material resources, reducing the rate of defective products, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

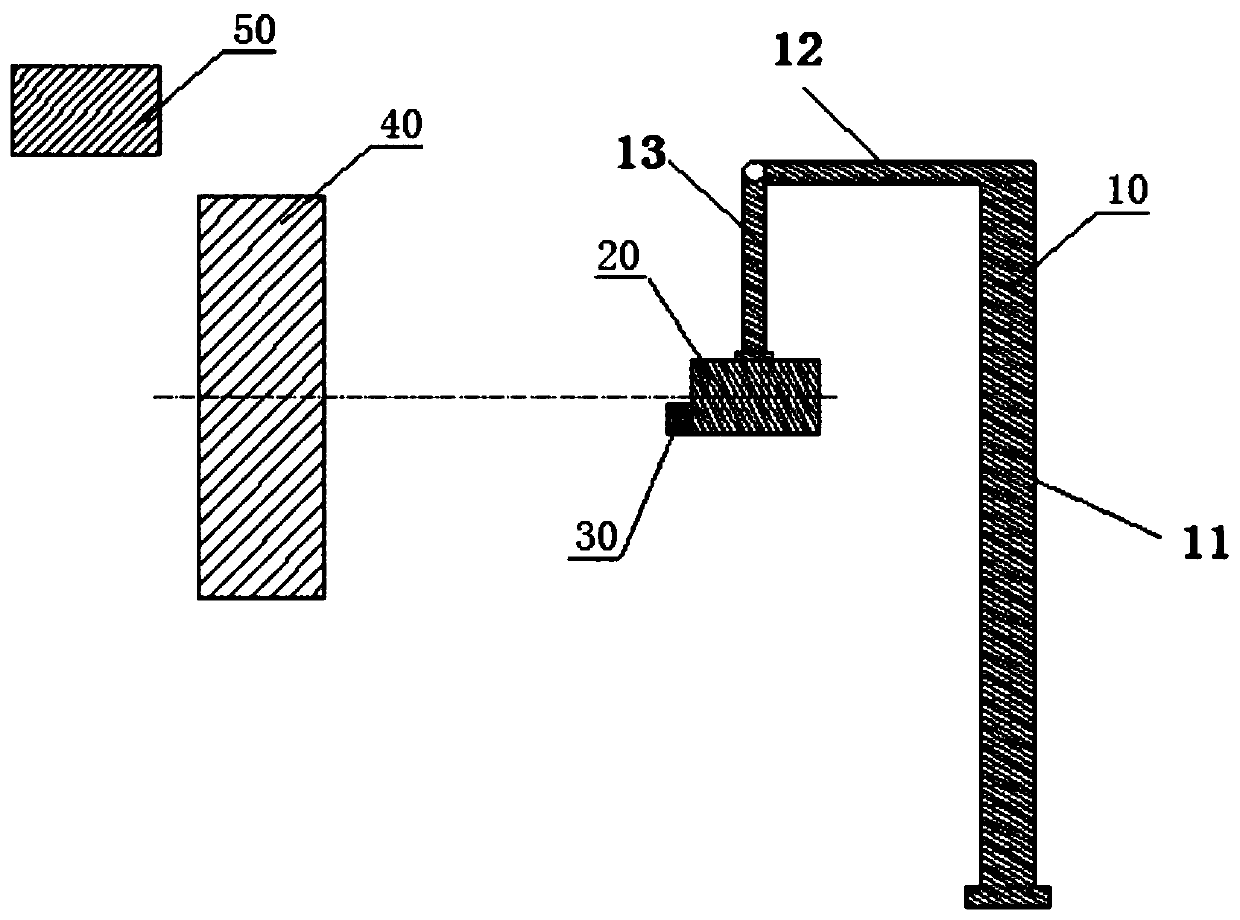

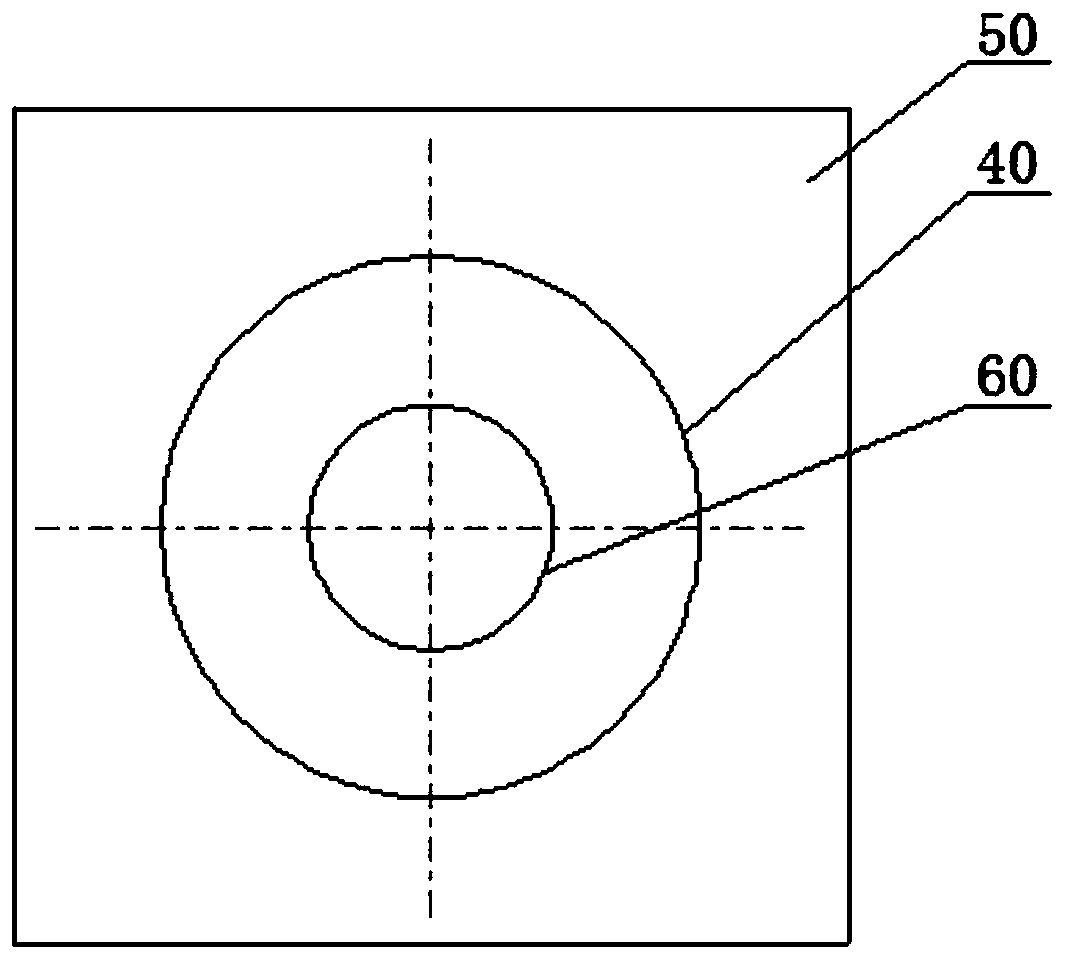

[0036] Such as Figure 1~5 , a kind of insulated sheath mold deflection adjustment device, the head 1 of the mold has a mold cover and a mold core 60 positioned in the mold cover, the deflection adjustment device includes a bracket 10, the bracket 10 is provided with an image acquisition device, and the mold of the image acquisition device The centerline of the core 6 coincides with the centerline of the machine head 1, and the auxiliary device also includes a display device for displaying the image of the image acquisition device;

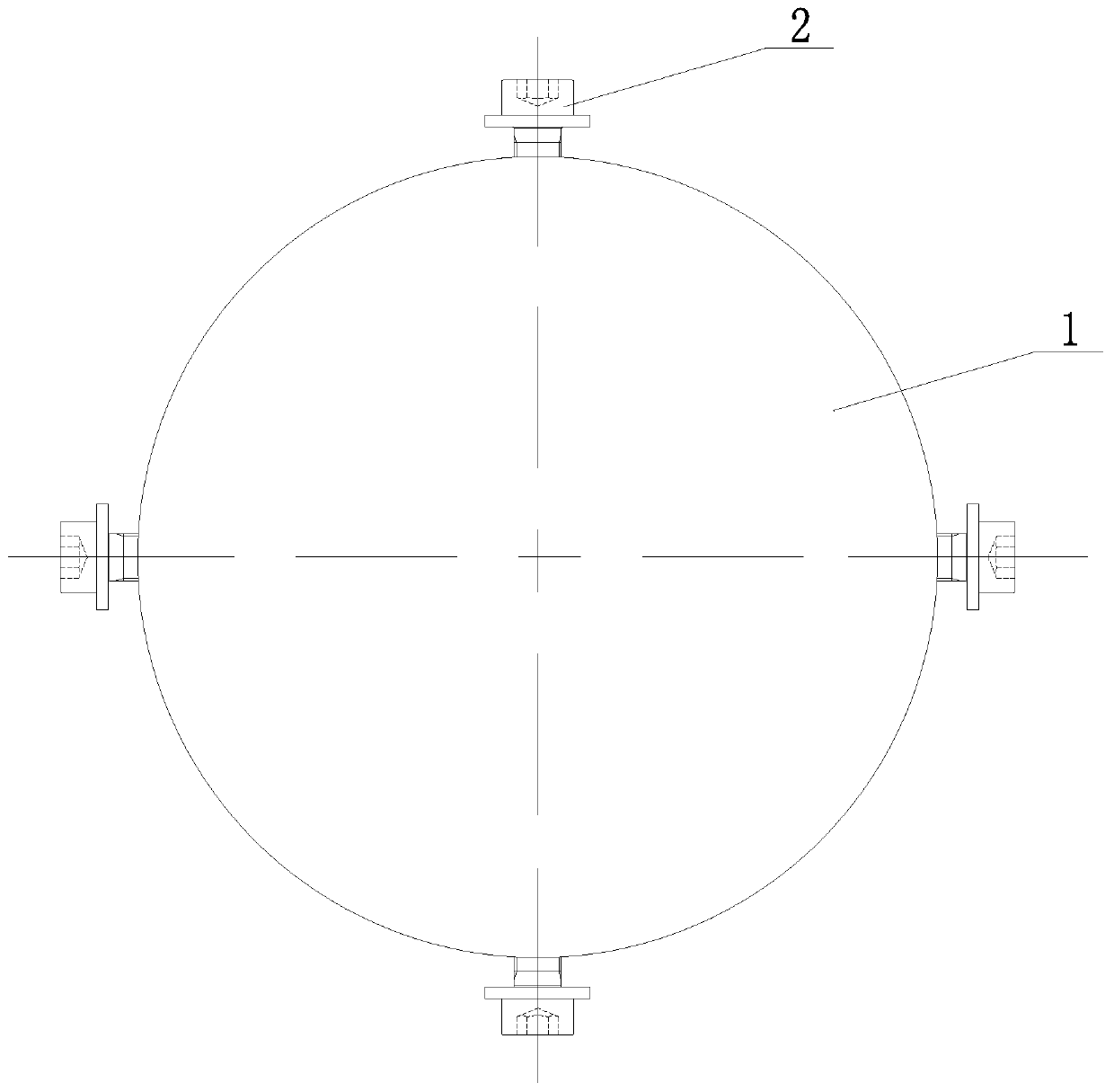

[0037] The machine head 1 is equipped with a deflection adjustment screw 2 for adjusting the relative position of the mold sleeve and the mold core 60 in the machine head 1. The deviation adjustment screw 2 includes a nut 3 and a bolt 5, and a scale is fixed between the nut 3 and the bolt 5 The dial 4 has a rotation scale indicated on the dial 4 , and the rotation scale on the dial 4 is proportional to the displacement of the screw thread 6 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com