Hydraulic control system for electric-hydraulic proportional numerical control bending machine

A hydraulic control system, electro-hydraulic proportional technology, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve the problems of low precision, large space occupation, unstable movement and other problems of bending machines, and achieve accurate operation control. Simple, low equipment cost, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

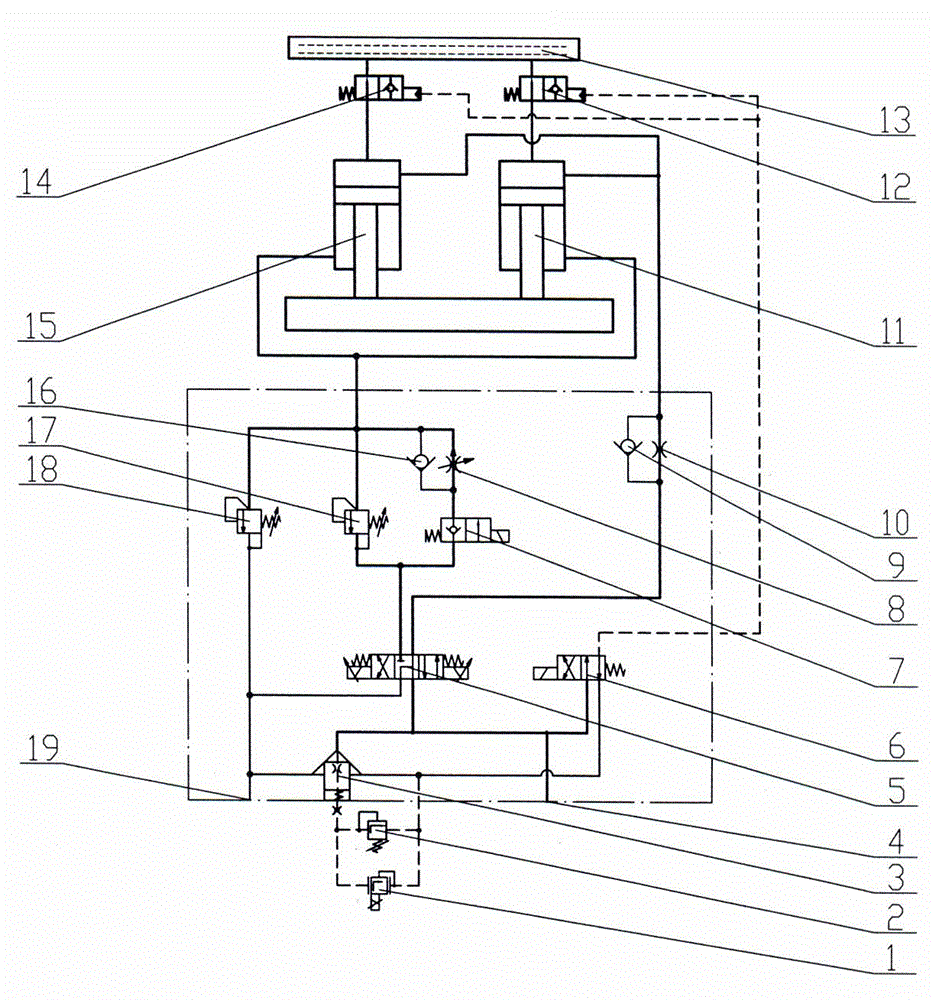

[0009] refer to figure 1 , the hydraulic control system of the electro-hydraulic proportional numerical control bending machine of the present invention is composed of a proportional overflow valve 1, an overflow valve 2, a two-way cartridge overflow valve 3, a main valve oil inlet 4, and a three-position four-way electromagnetic switch. Directional valve 5, two-position four-way electromagnetic reversing valve 6, electromagnetic stop valve 7, throttle valve 8, No. 1 one-way valve 9, damper 10, No. 1 oil cylinder 11, No. 1 filling valve 12, Oil tank 13, No. 2 liquid filling valve 14, No. 2 oil cylinder 15, No. 2 one-way valve 16, support valve 17, safety valve 18 and main valve oil return port 19, main valve oil inlet 4 and two-way The oil inlet of the cartridge overflow valve 3 is connected, the main valve oil inlet 4 is connected with the oil inlet of the two-position four-way electromagnetic reversing valve 6, the main valve oil inlet 4 is connected with the three-position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com