Buffer base for air compressor

A technology of air compressors and buffer blocks, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc. It can solve the problems of affecting the service life of air compressors, frequent air compressor failure rates, and incomplete shock absorption measures and other problems, to achieve the effect of comprehensive shock absorption, avoid left and right shaking, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

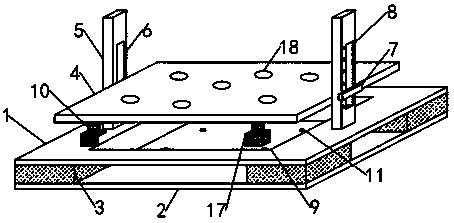

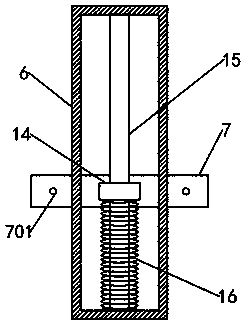

[0032] see Figure 1 to Figure 6 , a buffer base for air compressors, including an upper base 1 and a connecting column 5, and the connecting column 5 is fixedly installed in the middle of both ends of the surface of the upper base 1:

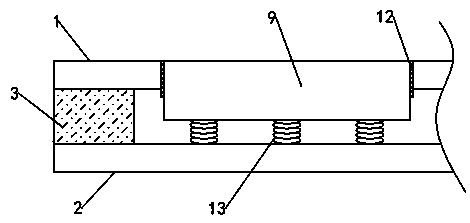

[0033] Upper base 1 comprises lower base 2, buffer block 3, spring column 301, buffer groove 302, mounting groove 9, mounting hole 11, chute 12, telescopic spring 13, buffer block 3 is fixedly installed around the bottom of upper base 1, The upper base 1 and the lower base 2 are fixedly connected through the buffer block 3, the lower base 2 is located directly below the upper base 1, the buffer block 3 is provided with a buffer groove 302 in the middle, and a spring column 301 is fixedly installed in the middle of the buffer groove 302, The two ends of the buffer tank 302 are fixedly mounted on the two ends of the inner wall of the buffer tank 302, and the top of the spring column 301 is fixedly connected to the inner top of the buffer block 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com