Dustproof and antifouling oil cylinder

An anti-fouling and oil-cylinder technology, which is applied in the directions of engine sealing, drilling equipment, drilling equipment and methods, etc., can solve the problems of inability to grasp the life of dust-proof sealing, limited dust-proof and anti-fouling ability, etc., so as to improve the sealing effect and the overall The effect of reduced structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

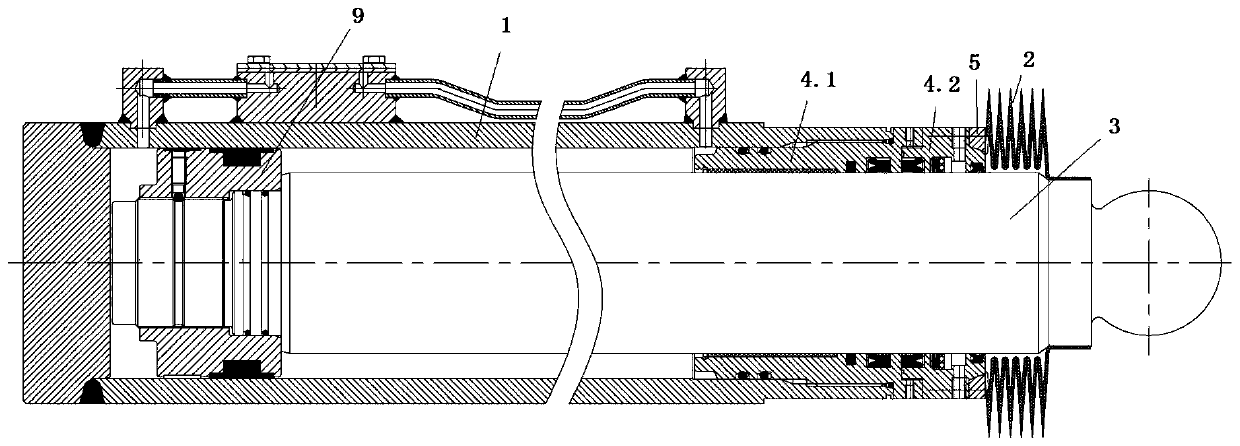

[0039] see Figure 1-Figure 3 , a dust-proof and anti-fouling oil cylinder, including a cylinder 1, a piston 9, a piston rod 3, a sealing connector 4 and a dust cover 2, the details are as follows:

[0040] One end of the piston rod 3 is connected with a piston 9 arranged in the cylinder 1 .

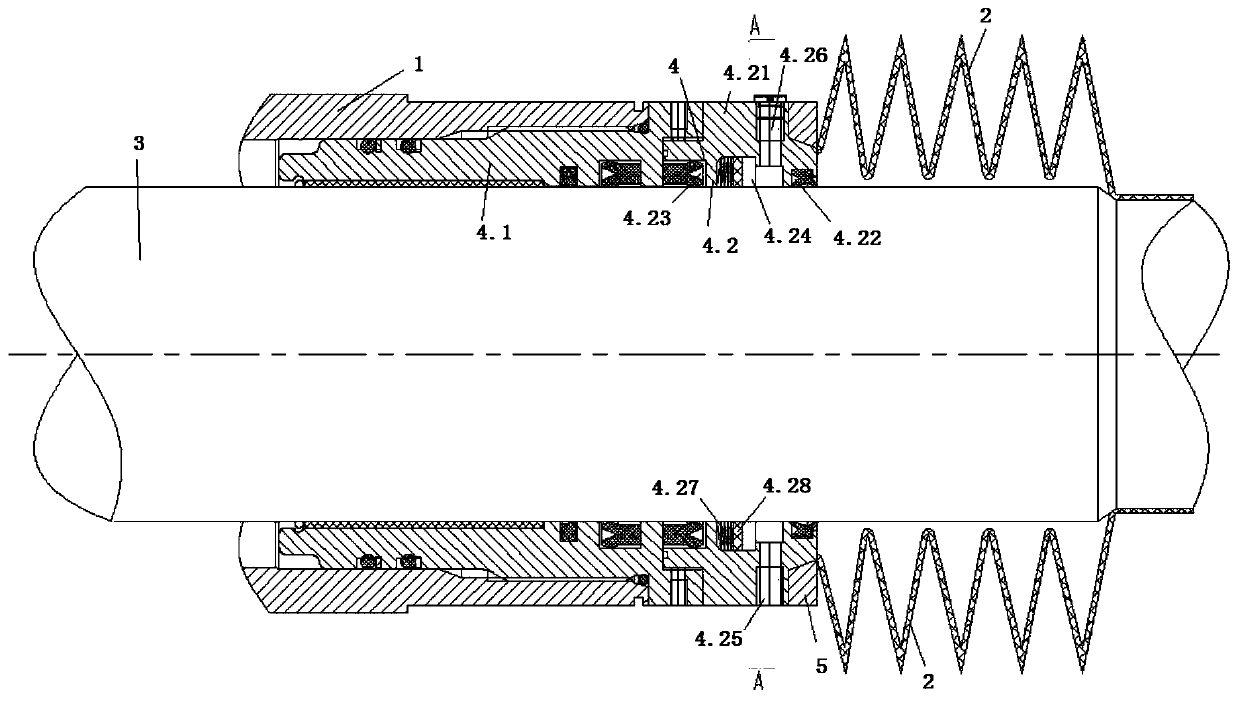

[0041] The sealing connector 4 includes a pressure detection component 4.3, a guide sleeve 4.1 and an anti-fouling ring 4.2 both sleeved on the piston rod 3; the guide sleeve 4.1 is located between the inner wall of the cylinder 1 and the piston rod 3 Between; the antifouling ring 4.2 is detachably connected to the guide sleeve 4.1 through threads.

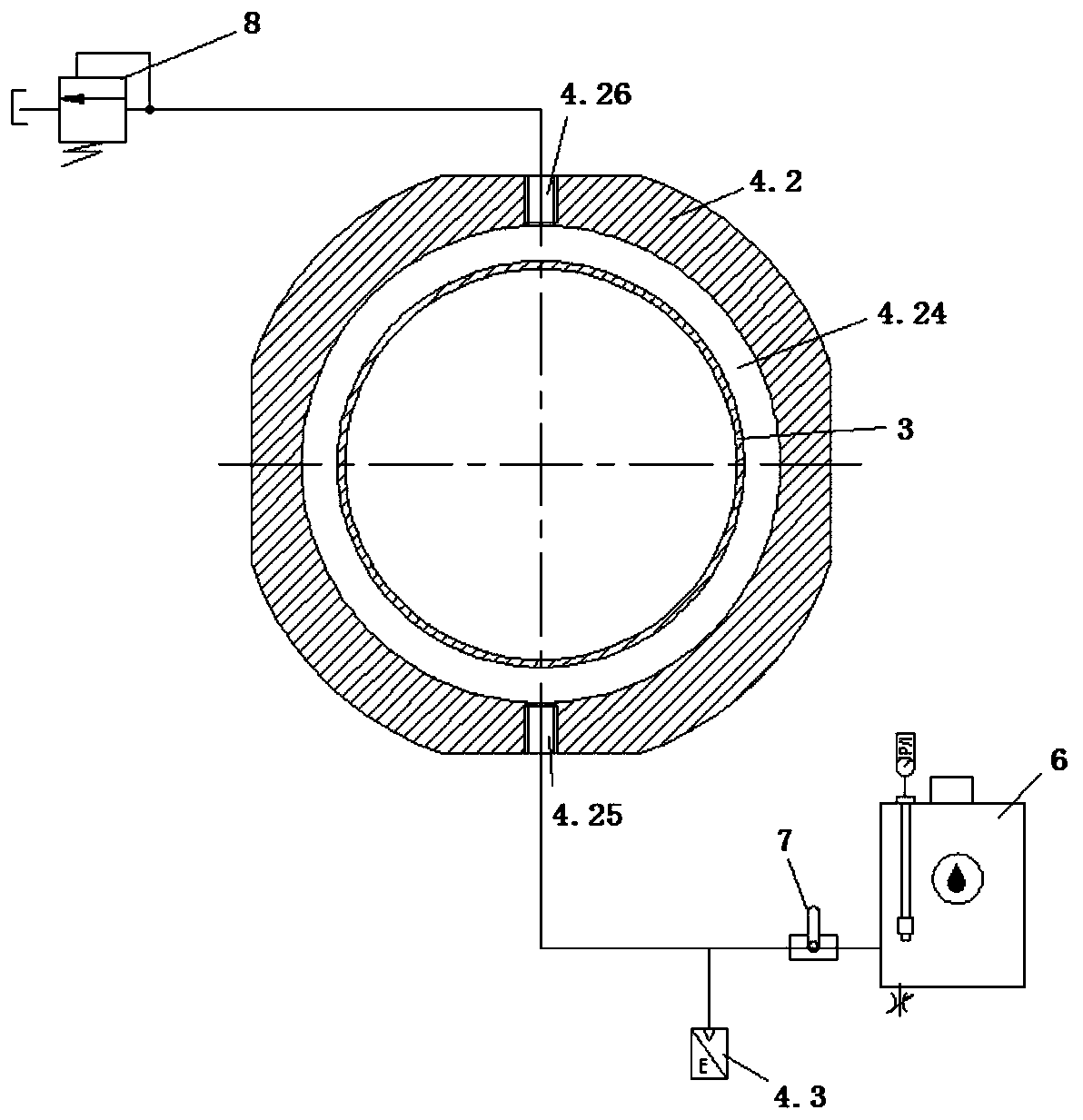

[0042] Preferably, the antifouling ring 4.2 includes a body 4.21, a first installation groove 4.22, a second installation groove 4.23, a lubricating oil receiving chamber 4.24, a lubricating oil injection port 4.25 and an exhaust overflow port 4.26, see Figure 4, the first installation groove 4.22 and the second installation groove 4.23 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com