Damping device for textile machinery

A technology of shock absorption device and textile machinery, applied in spinning machines, mechanical equipment, textiles and papermaking, etc., can solve the problems of insufficient heat dissipation, vibration, increased workshop noise, etc., so as to improve the shock absorption effect and prolong the service life. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

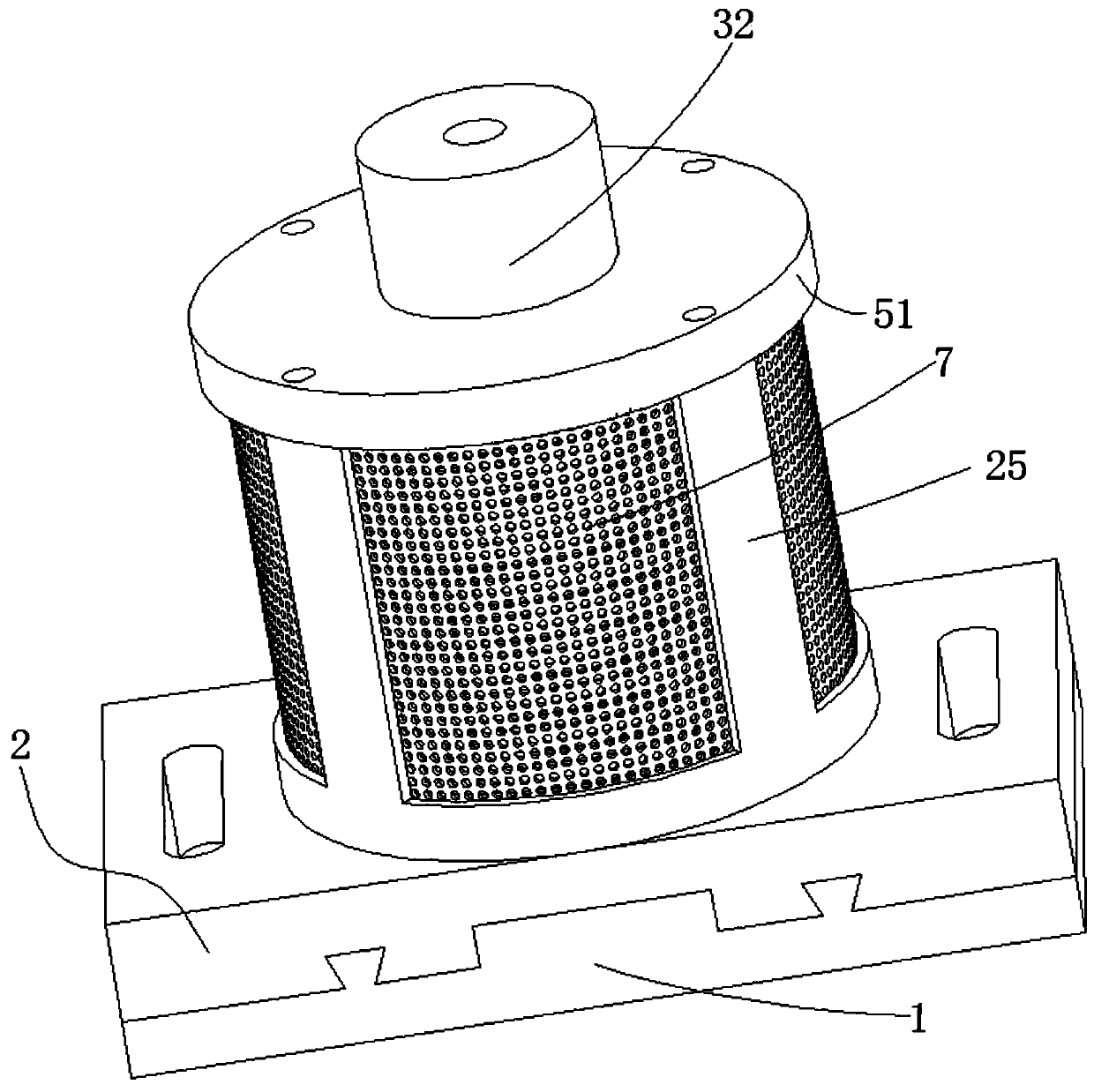

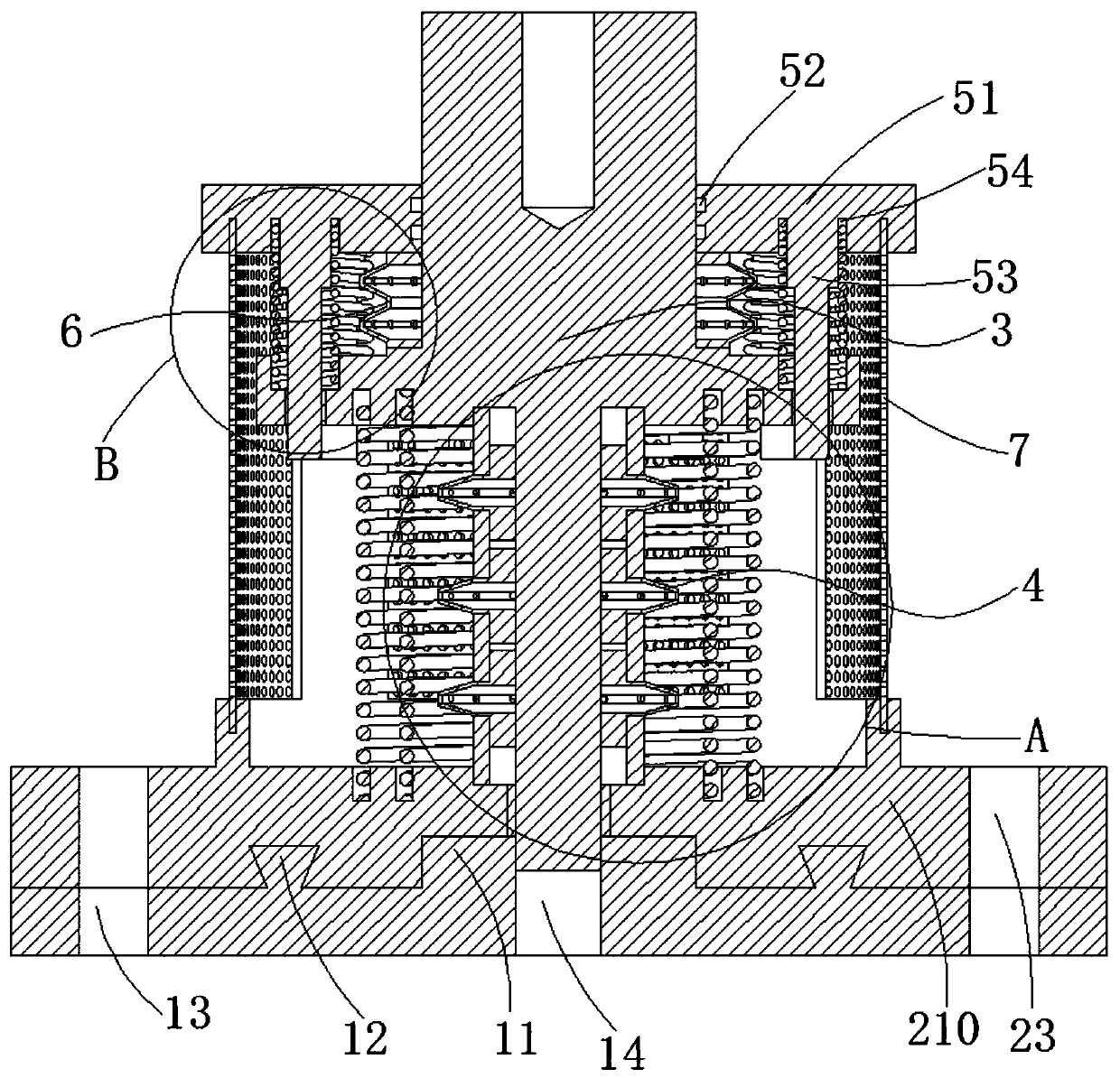

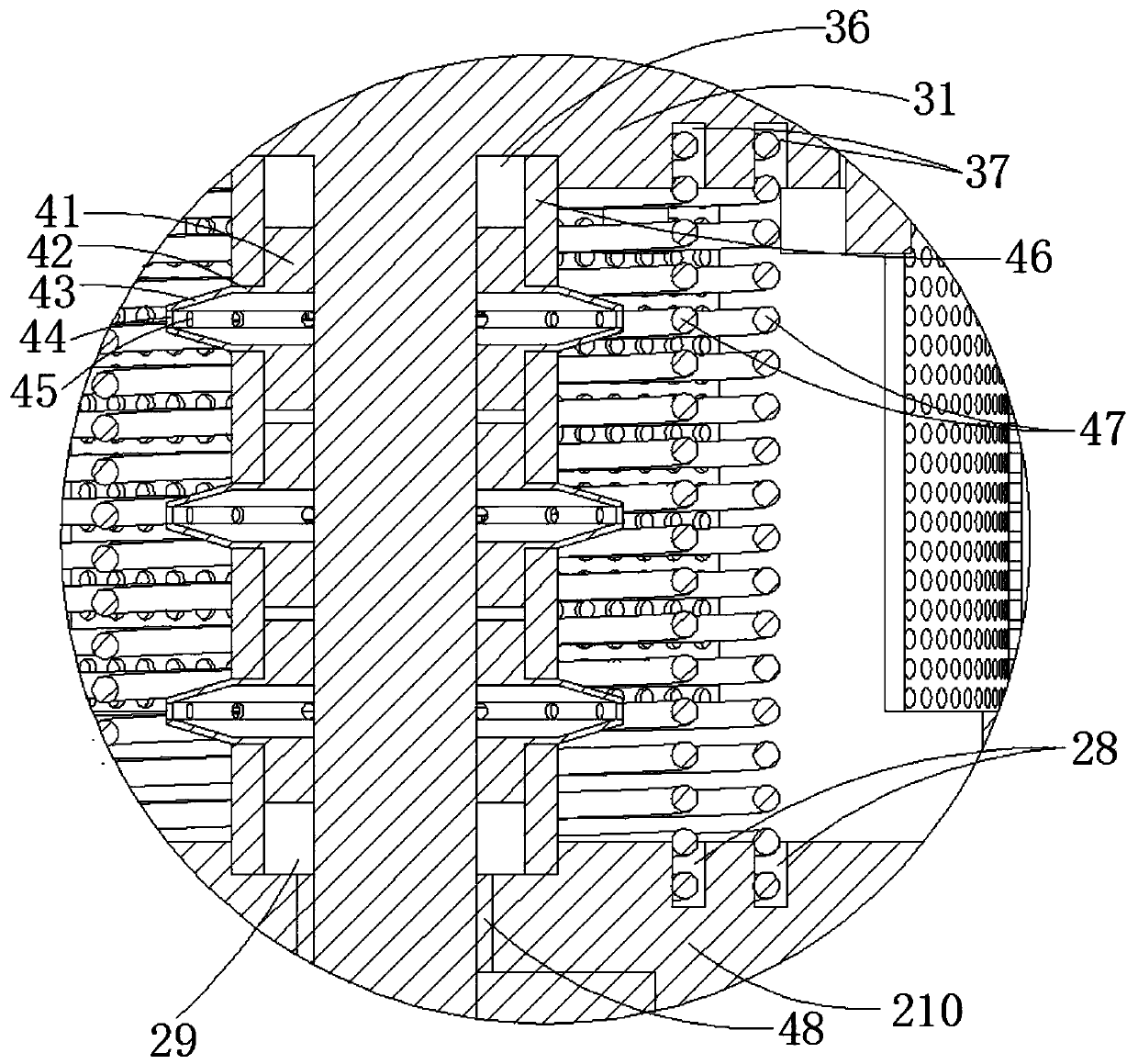

[0027] Such as Figure 1 to Figure 11 As shown, a shock absorbing device for textile machinery includes a base 2, an upper cover 5, a filter screen 7 and a bearing plate 3, the base 2 includes a square seat 210, and the center of the upper end surface of the square seat 210 extends upwards Form the convex ring 24 of the base, and the periphery of the convex ring 24 of the square seat body 210 is provided with a waist-shaped hole 23 of the base. Square structure, the base shock-absorbing pad 1 and the square base body 210 have the same length and width, the base shock-absorbing pad 1 is provided with a shock-absorbing pad waist hole 13 that penetrates up and down, the shock-absorbing pad waist hole 13 and the base waist hole 23 are opposite up and down, The waist-shaped hole 13 of the shock-absorbing pad and the waist-shaped hole 23 of the base are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com