Method for measuring contaminated soil amount of screen scarifier

A technology of quantity measurement and screen cleaning machine, applied in the direction of measuring device, track superstructure, instruments, etc., can solve the problem that the screen cleaning machine cannot calculate and detect the amount of sewage conveyed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

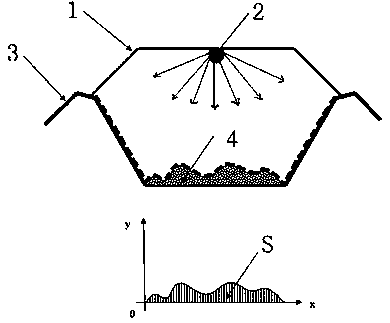

[0016] like figure 1 As shown, the soil measuring device of the present invention includes a sensor bracket 1, a profile sensor 2 and a rotational speed sensor; wherein the sensor bracket 1 is installed above the dirt conveyor belt 3, and the profile sensor 2 is installed on the sensor bracket 1 for real-time continuous scanning The profile of the dirt 4; the speed sensor is installed at the end of the driving shaft of the dirt conveyor belt to continuously monitor the rotation speed of the dirt conveyor belt in real time. Wherein the contour sensor 1 can adopt a laser sensor and other sensors with corresponding functions, and the rotational speed sensor can adopt an incremental encoder and other sensors with corresponding functions.

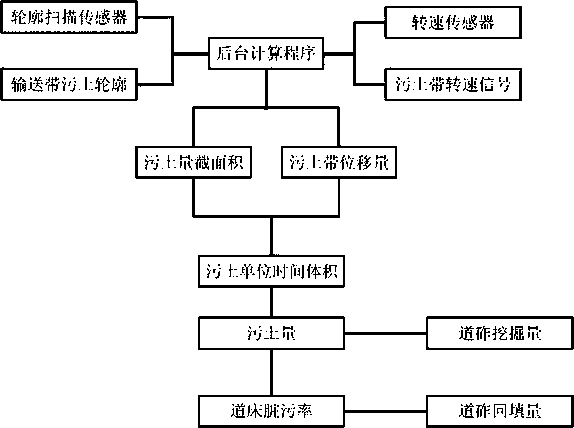

[0017] like figure 2 As shown, the measurement method of the present invention is to establish a set of mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com