A real-time monitoring device and method for TBM hob loss state

A real-time monitoring and hob technology, which is applied in the field of real-time monitoring device for TBM hob wear state, which can solve the problems of affecting the measurement results, affecting the rock breaking ability of the hob, and difficult to monitor the abnormal wear of the hob and the hob.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

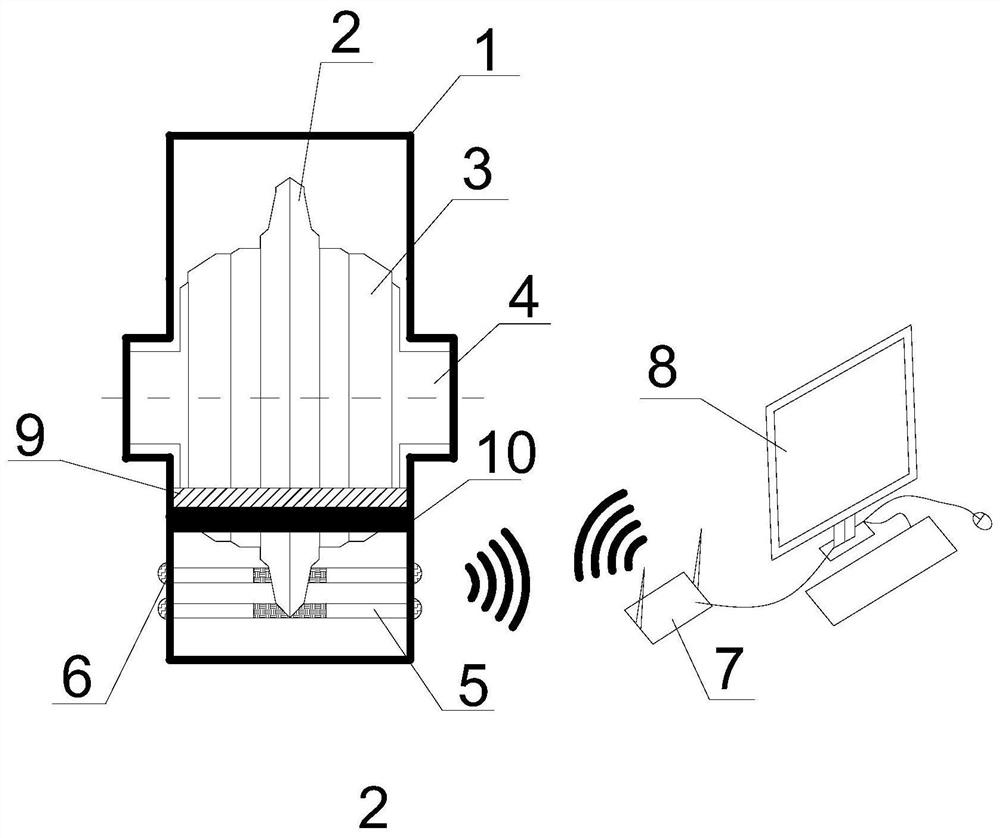

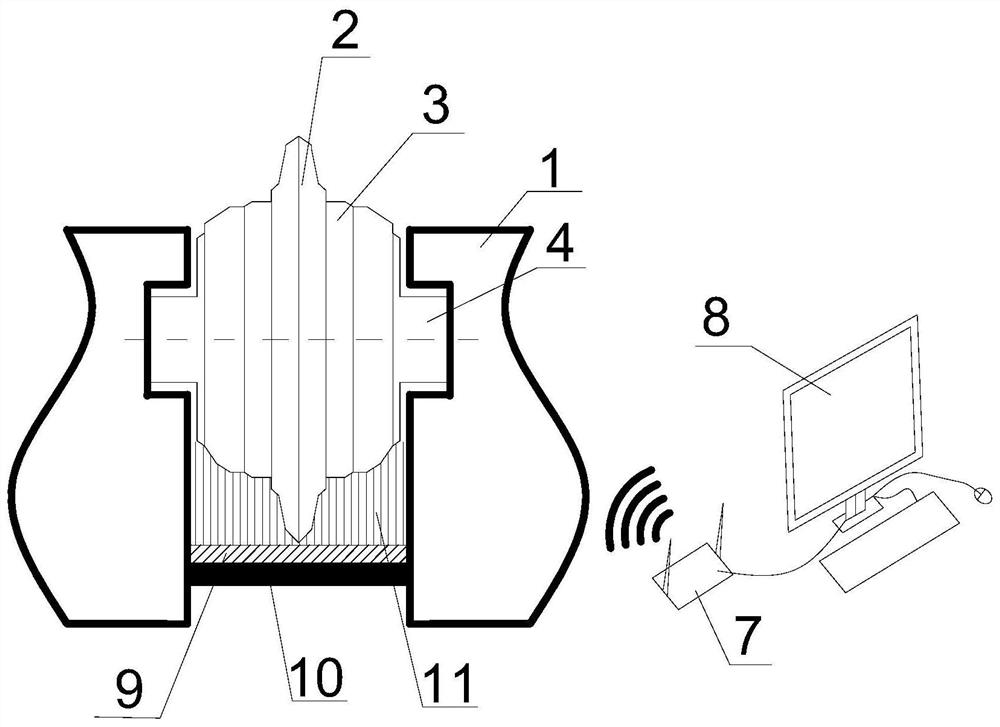

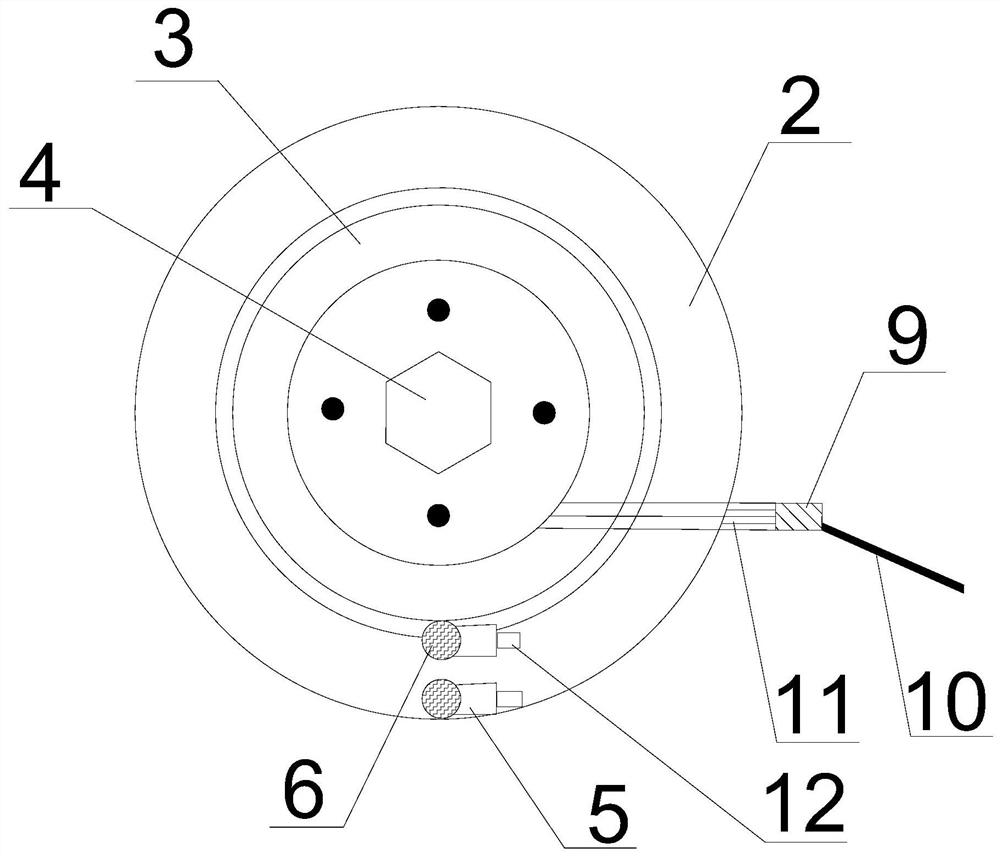

[0045] In a typical implementation of the present application, such as Figure 1-Figure 7 As shown, a real-time monitoring device for TBM hob loss status is proposed.

[0046] Including a loss sensing module 5, a data acquisition and sending module 6, a processor, and a hob cleaning module, the loss sensing module 5 includes a protective shell, a reed 12, and a semiconductor self-compensating strain gauge 15; the data acquisition And transmission module 6 comprises data acquisition circuit, single-chip microcomputer, wireless signal transmission device, and data acquisition circuit converts the resistance variation of the strain gauge 15 of semiconductor self-compensation type into voltage variation, and the voltage signal is converted into digital signal after being processed by single-chip microcomputer and is sent by wireless signal Device sends; Described processor comprises data receiving module 7, also comprises wireless signal receiving device, single-chip microcomputer...

Embodiment 2

[0058] In another typical embodiment of the present application, a method for real-time monitoring of the wear state of the TBM hob is provided, using the real-time monitoring device for the wear state of the TBM hob as described in any one of the above.

[0059] Select the monitoring target points on each part of the hob, and arrange the loss sensing module;

[0060] The loss perception module collects the vibration signal when the hob is driving, and sends the vibration signal to the processor through the data collection and sending module;

[0061] After the processor receives the vibration signal, it compares the collected vibration signal with the vibration signal database of the hob loss state, obtains the loss state of the hob at this time, and realizes monitoring.

[0062] Further, the vibration signal database of the loss state of the hob is established by the following process:

[0063] Select the monitoring target points at different parts of the hob, and select th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com