Aircraft engine cable intermittent fault detector and detection method thereof

A technology for aircraft engine and fault detection, which is applied in the direction of fault location and fault detection according to conductor type, so as to achieve the effect of convenient and timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

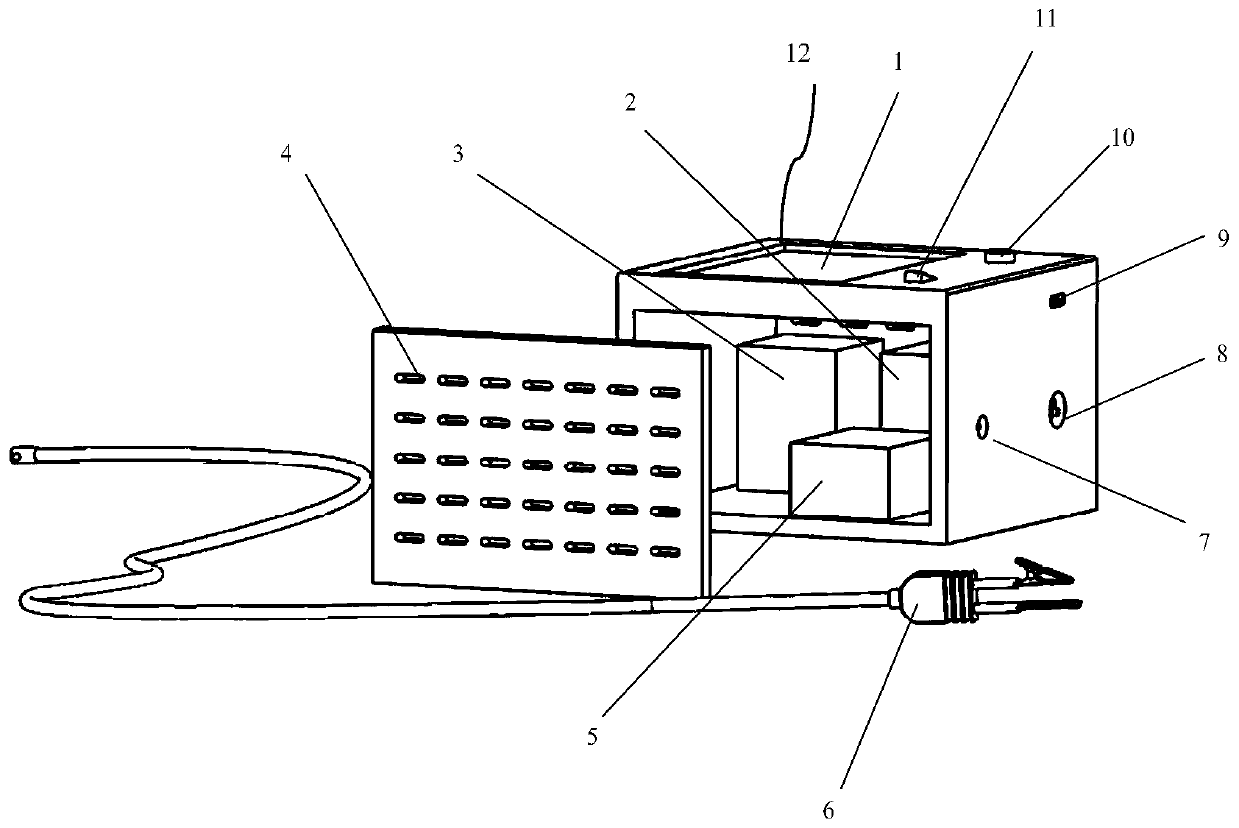

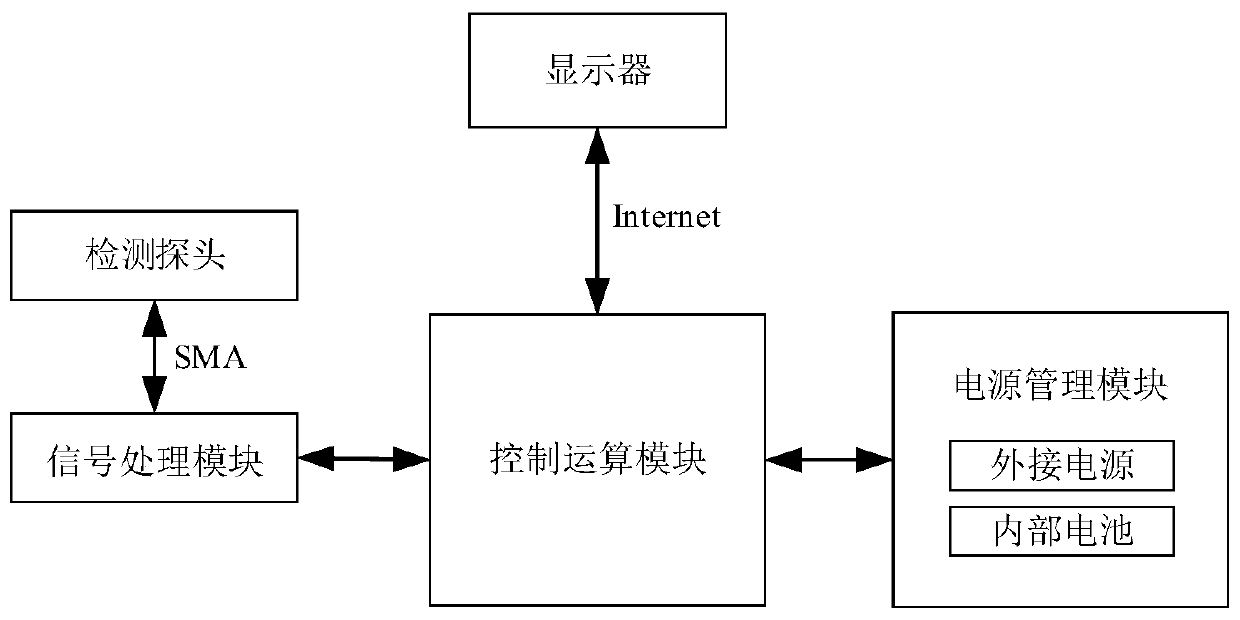

[0044] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

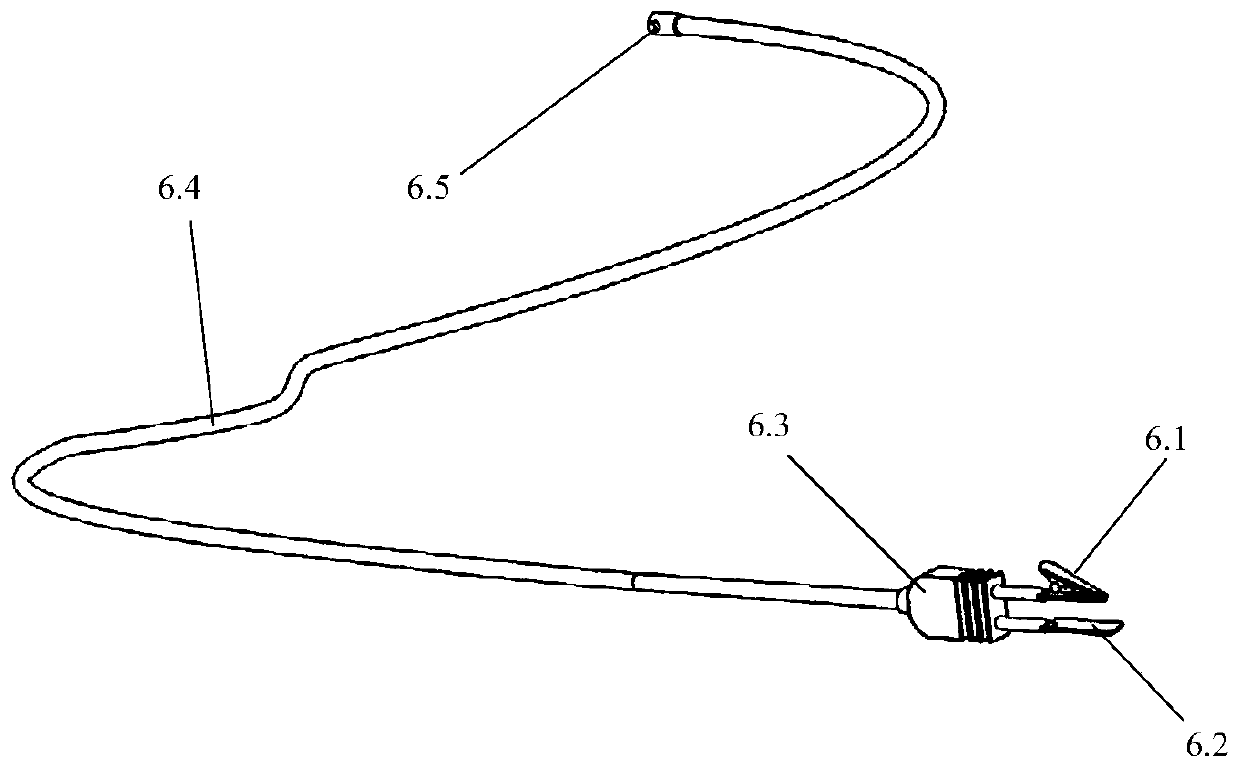

[0045] The inventor noticed during the invention process that the violent vibration of the engine during operation may easily lead to failures such as loosening of the core crimping point of the electrical connector of the aircraft engine cable, partial strand breakage of the cable, and the like. The characteristics of this kind of fault are more prominent when the engine is running, and the fault information is not clear when it is static, showing obvious int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com