Interval adaptive planning method for five-axis machining feed speed

A feed rate, self-adaptive technology, used in instruments, digital control, control/regulation systems, etc., can solve problems such as difficulty in application, affecting the stability of feed motion, and heavy computational burden, achieving high computational efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

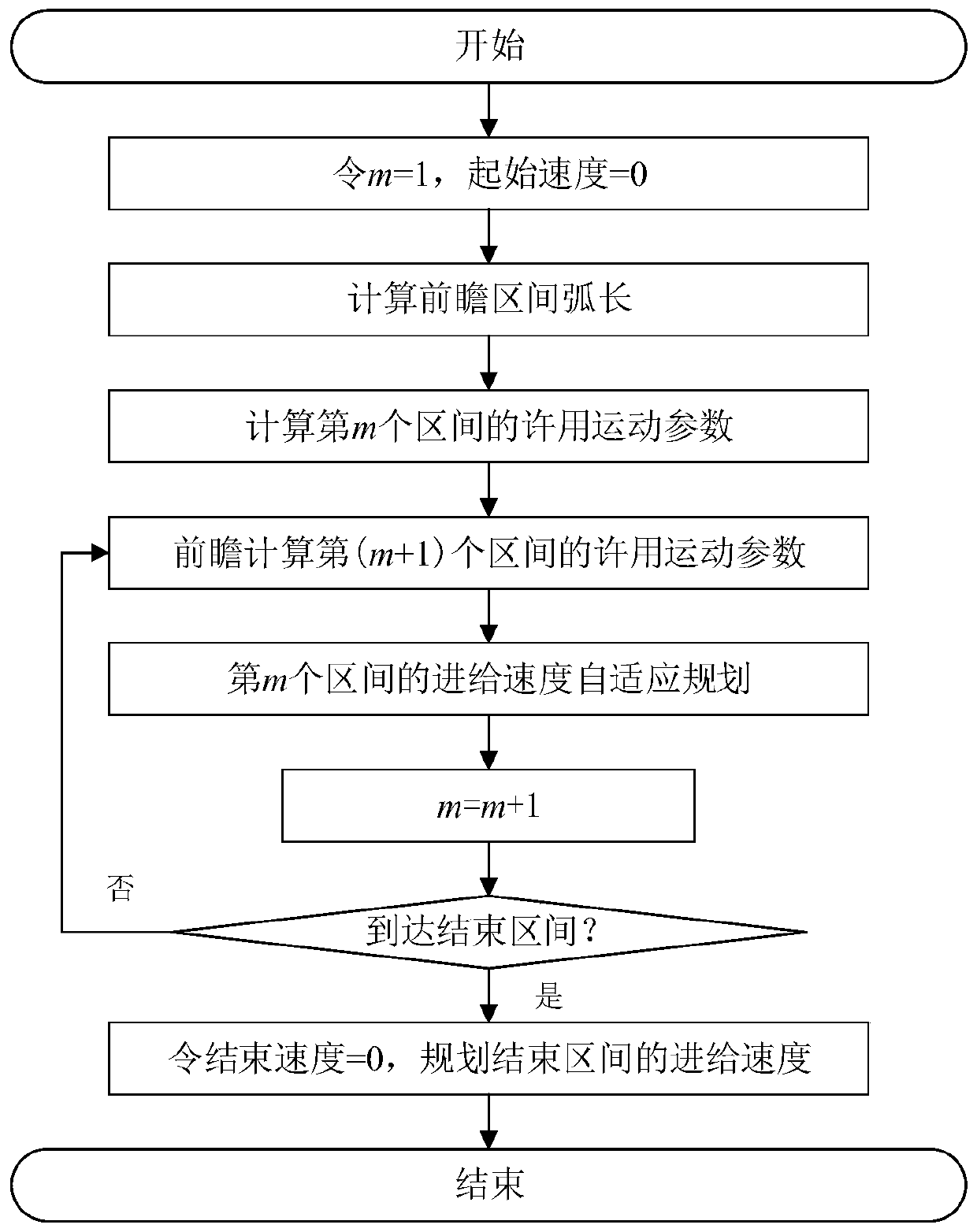

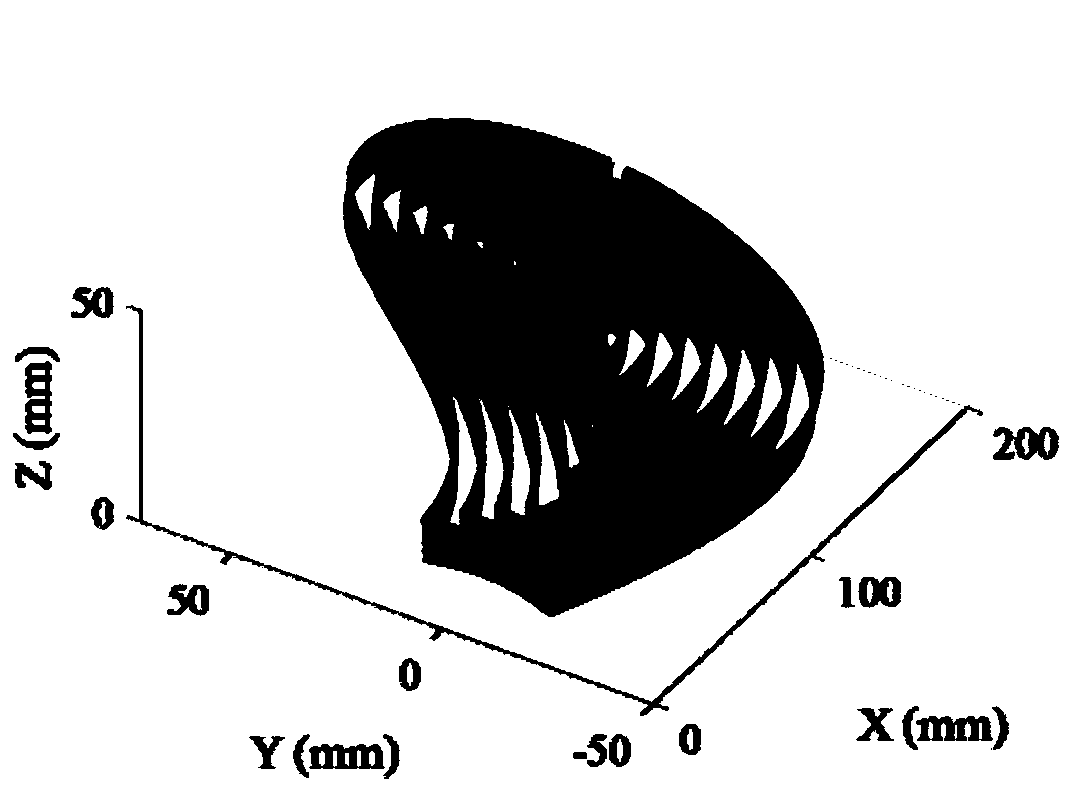

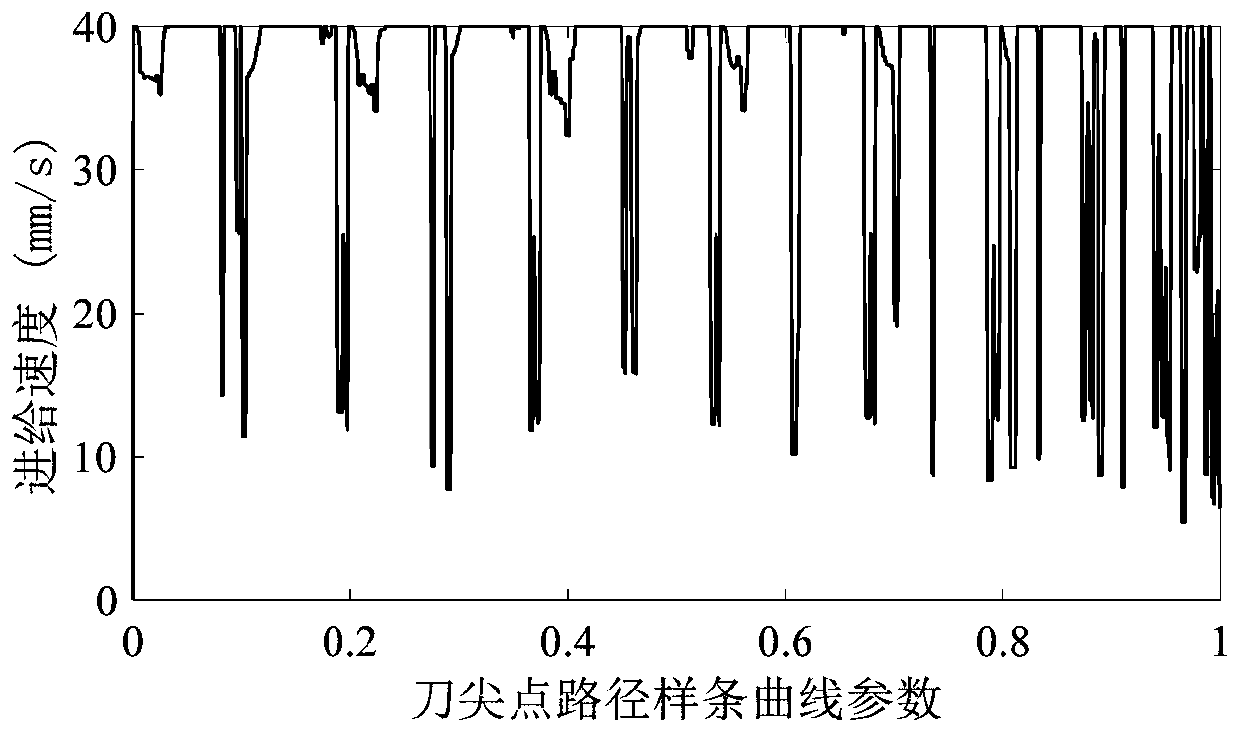

[0049] The purpose of the present invention is to overcome the defects of the prior art, and to invent an interval self-adaptive planning method for five-axis machining feed rate. The method applies a forward-looking window to cut off the influence of the curve shape outside the window on the feed rate planning of the current position, based on The differential principle plans the feed rate profile that satisfies the constraints of the axis driving capability area by area, and realizes the efficient generation of the feed rate of the five-axis long spline curve path. The technical solution of the present invention is an interval self-adaptive planning method for five-axis machining feed rate, which is characterized in that the method is based on the differential principle, determines the allowable motion parameters of the current interval, and calculates the drop rate und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com