Safety management method for spacecraft orbit control pipeline pressure intensity

A technology for safety management and spacecraft, which is applied in the field of safety management of spacecraft orbit control pipeline pressure, can solve problems such as the difficulty of determining the temperature control threshold, achieve the effects of reducing the number of switching operations, improving product reliability, and occupying less resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

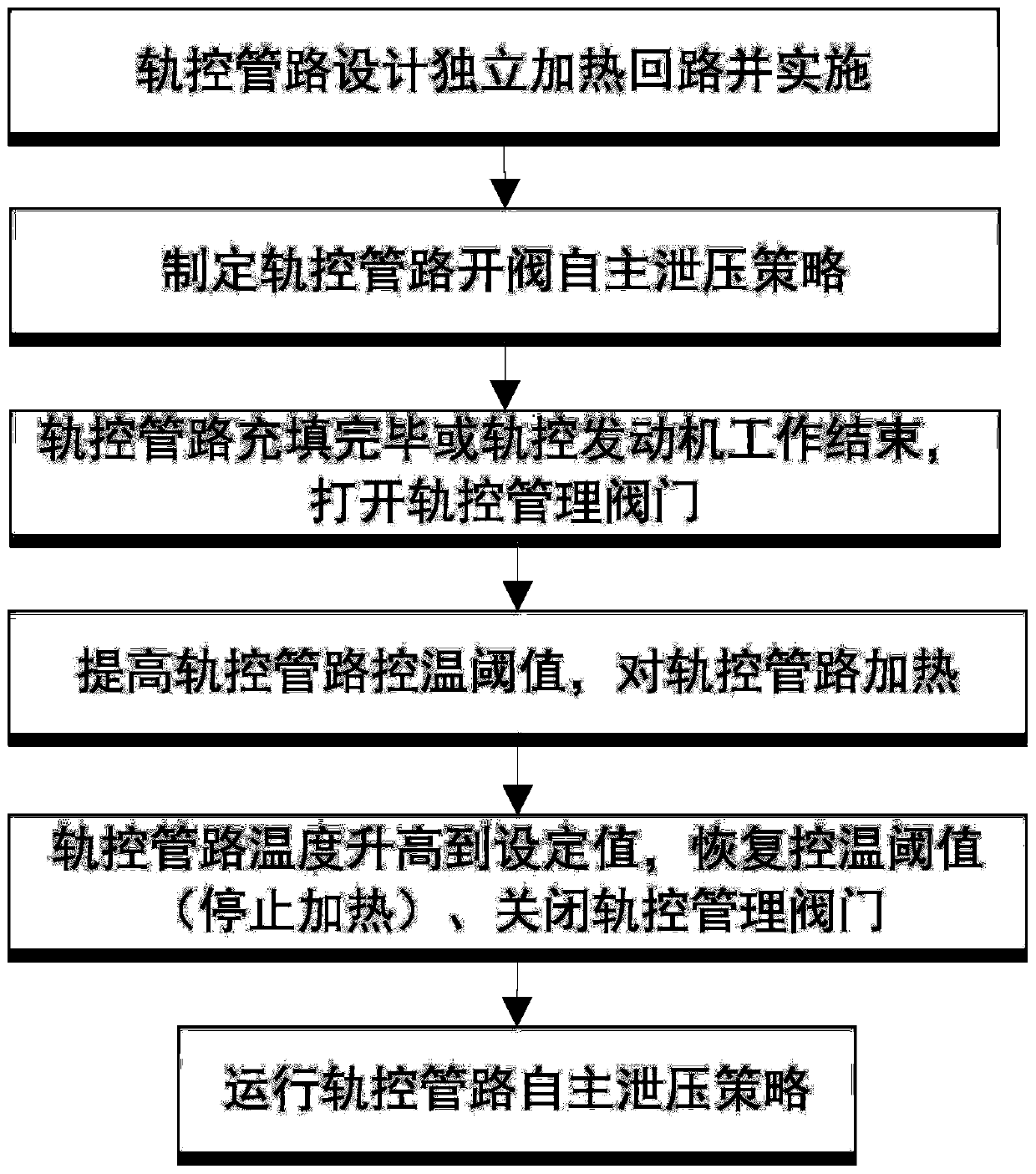

Method used

Image

Examples

Embodiment

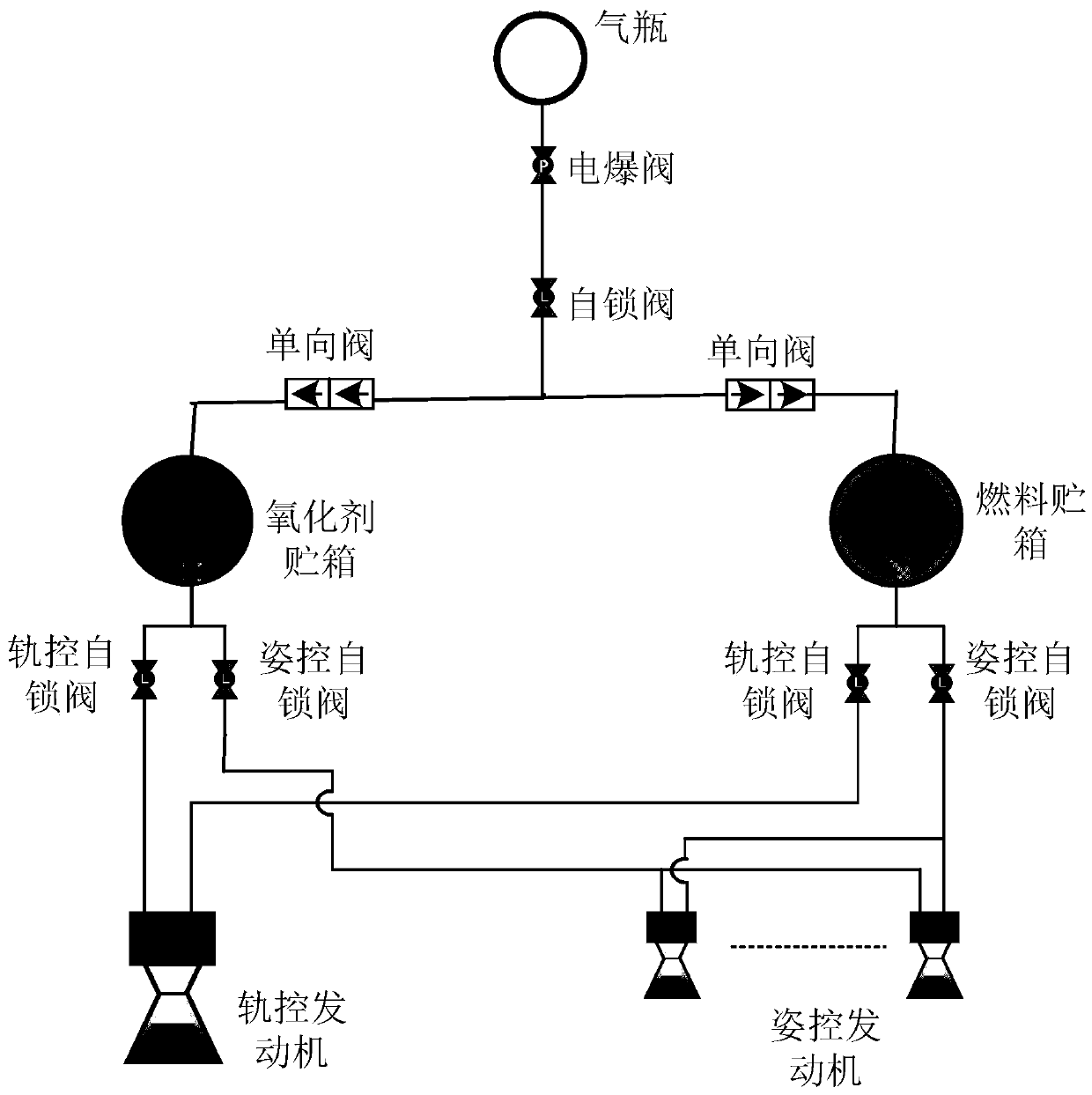

[0031] An aerospace probe propulsion system, which adopts a dual-unit attitude and orbit control unified supply system, and the attitude control engine and the orbit control engine are independently managed. The system principle is as follows: Figure 5 As shown, it is composed of gas cylinders, storage tanks, attitude control self-locking valves, orbital control self-locking valves, attitude control engines and orbital control engines. The steps for the detector to realize the pressure safety management of the rail control pipeline are as follows:

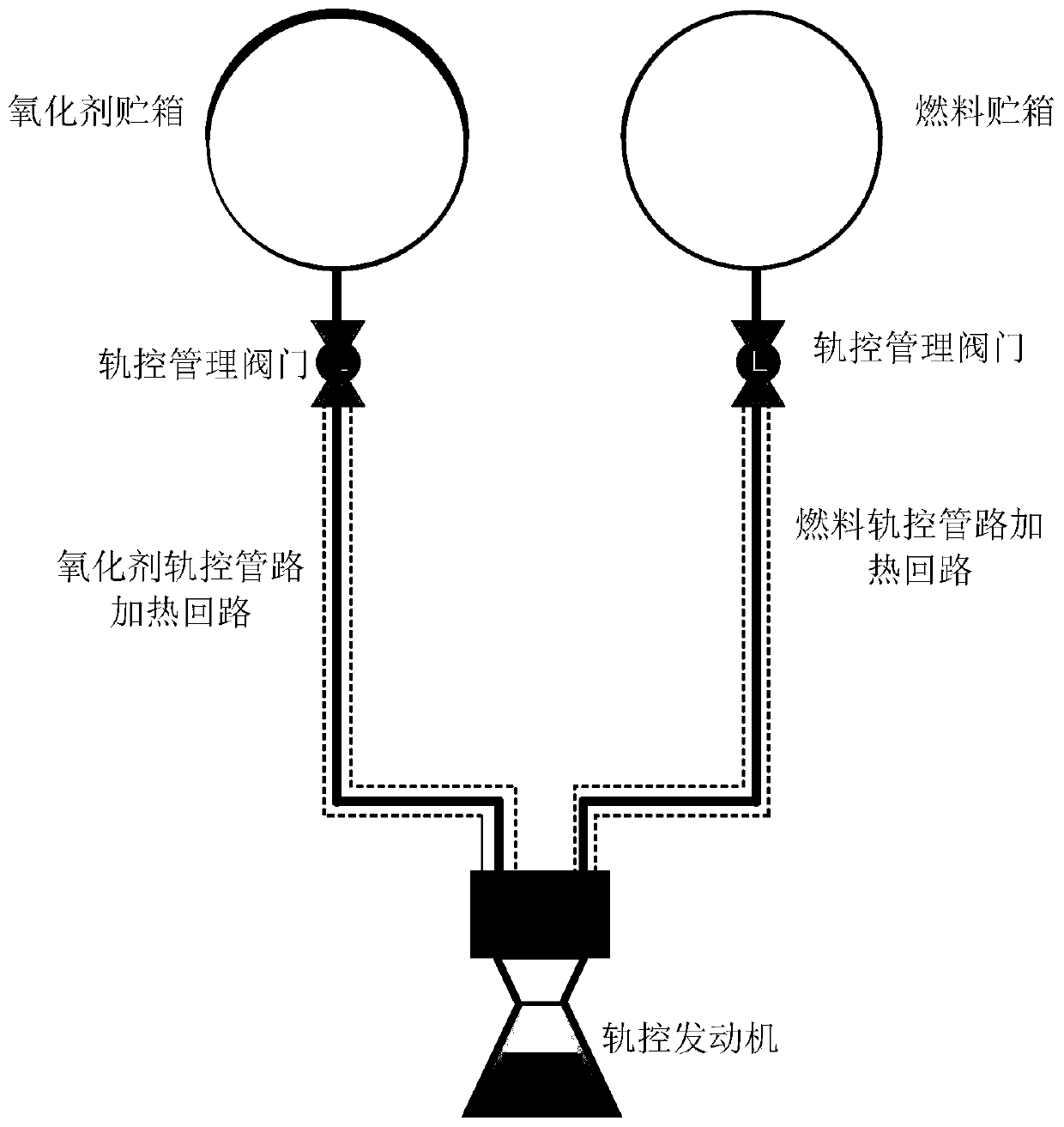

[0032] (1) Independent heating circuits are designed for the oxidant rail control pipeline and the fuel rail control pipeline. The ground test proves that the design of the heating circuit meets the requirements and can effectively heat the rail control pipeline.

[0033] (2) The autonomous pressure relief software of the rail control pipeline was developed, and the effectiveness was verified through ground tests. The autonomous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com