Feed structure of dielectric phase shifter

A phase shifter and medium technology, applied in circuits, electrical components, waveguide-type devices, etc., can solve the problems of antenna connection, inability to meet the miniaturization of 5G antennas, etc., and achieve the effect of avoiding loosening and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the drawings and embodiments, but it is not used as a basis for any restriction on the invention.

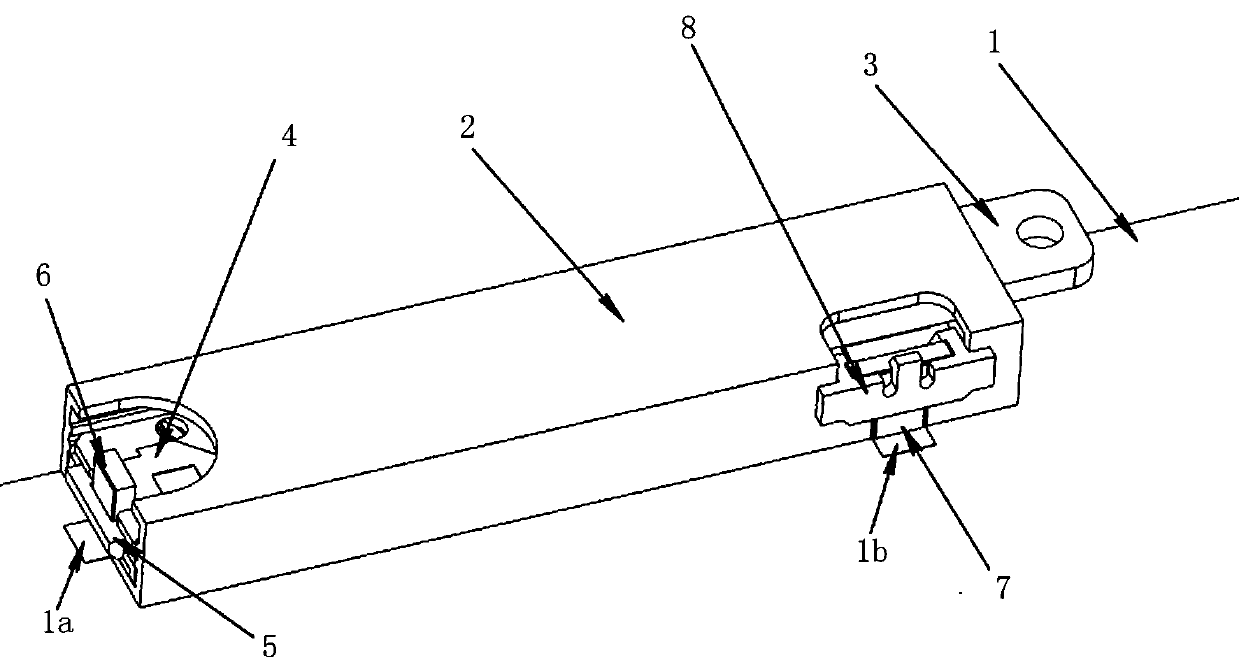

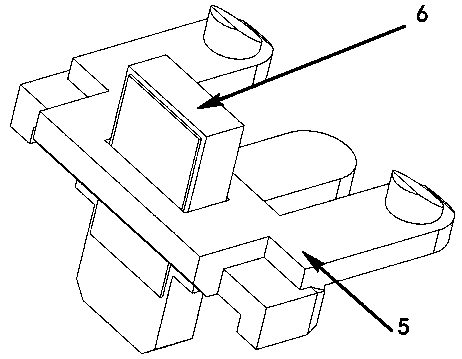

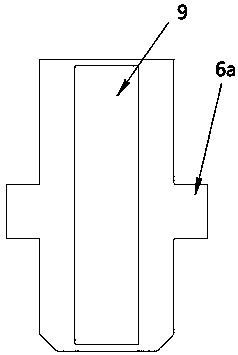

[0028] Referring to the drawings, a feed structure of a dielectric phase shifter. The dielectric phase shifter includes a bottom PCB feeder network 1 and a phase shifter cavity 2. The phase shifter dielectric plate 3 is installed in the phase shifter cavity 2 And the dielectric phase shifter PCB board 4, the phase shifter cavity 2 is provided with two notches corresponding to the input and output ports of the dielectric phase shifter PCB 4 respectively. One of the two notches is located in the phase shifter One end of the cavity 2 corresponds to the input port of the dielectric phase shifter PCB board 4, and the other gap is located at the other end of the phase shifter cavity 2, and corresponds to the output port of the dielectric phase shifter PCB board 4 . The feeding structure includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com