A bearing ring numerical control machine tool

A bearing ring, CNC machine tool technology, used in metal processing machinery parts, maintenance and safety accessories, metal processing and other directions, can solve problems such as inconvenience for workers to maintain machine tools, reduce vibration, reduce radiation range, and improve machining accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

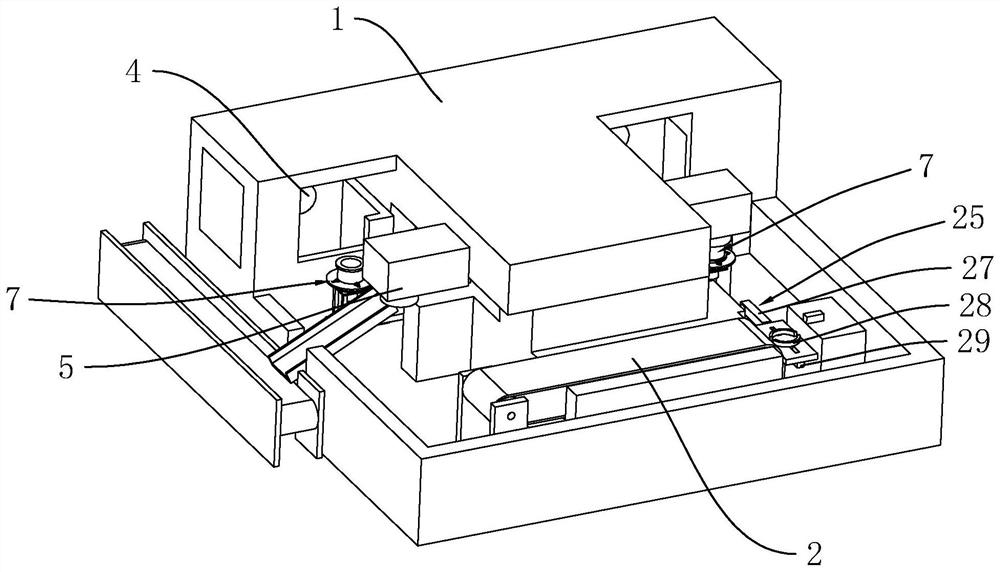

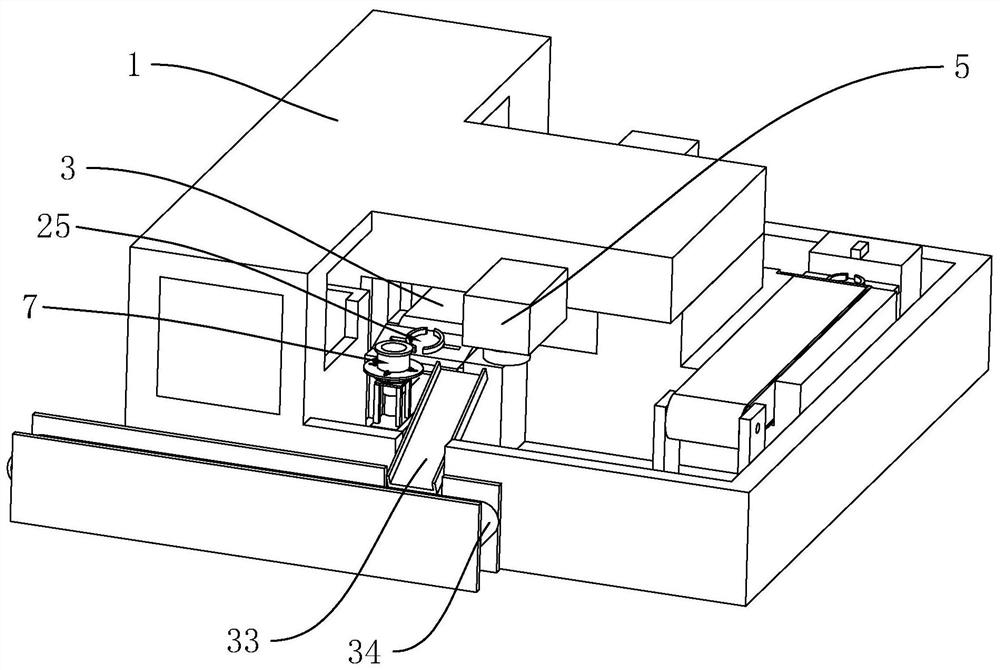

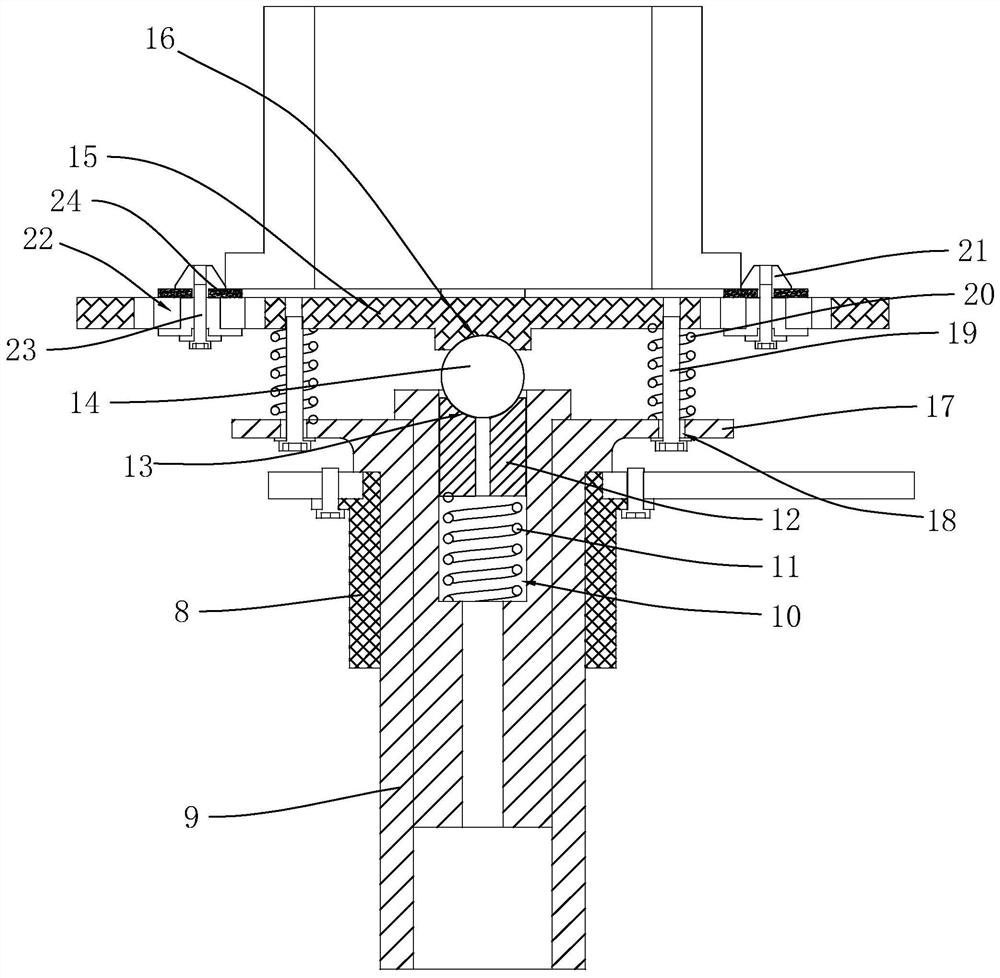

[0031] combine figure 1 and figure 2As shown, a bearing ring numerical control machine tool includes a body 1, a feed conveyor belt 2 is arranged on the body 1, and a return conveyor belt 3 is arranged on one side of the feed conveyor belt 2, the transmission directions of the two are parallel and opposite, and the return Knife turrets 4 are arranged at both ends of the side of the material conveyor belt 3 facing away from the feed conveyor belt 2, and a manipulator 5 corresponding to the turret 4 is arranged on the body 1, and the turret 4 is arranged on the body 1, and the turret 4 is fixedly distributed with many cutters 6 (not shown in the figure) used for bearing ring processing, and the axial direction of the cutter tower 4 is perpendicular to the transmission direction of the return conveyor belt 3. At this time, the setting range of the entire fusel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com