Bicycle without chain

A bicycle and chainless technology, which is applied to vehicle components, vehicle gearboxes, wheel transmissions, etc., can solve problems such as easy wear, immature technology of chainless bicycles, and short lifespan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

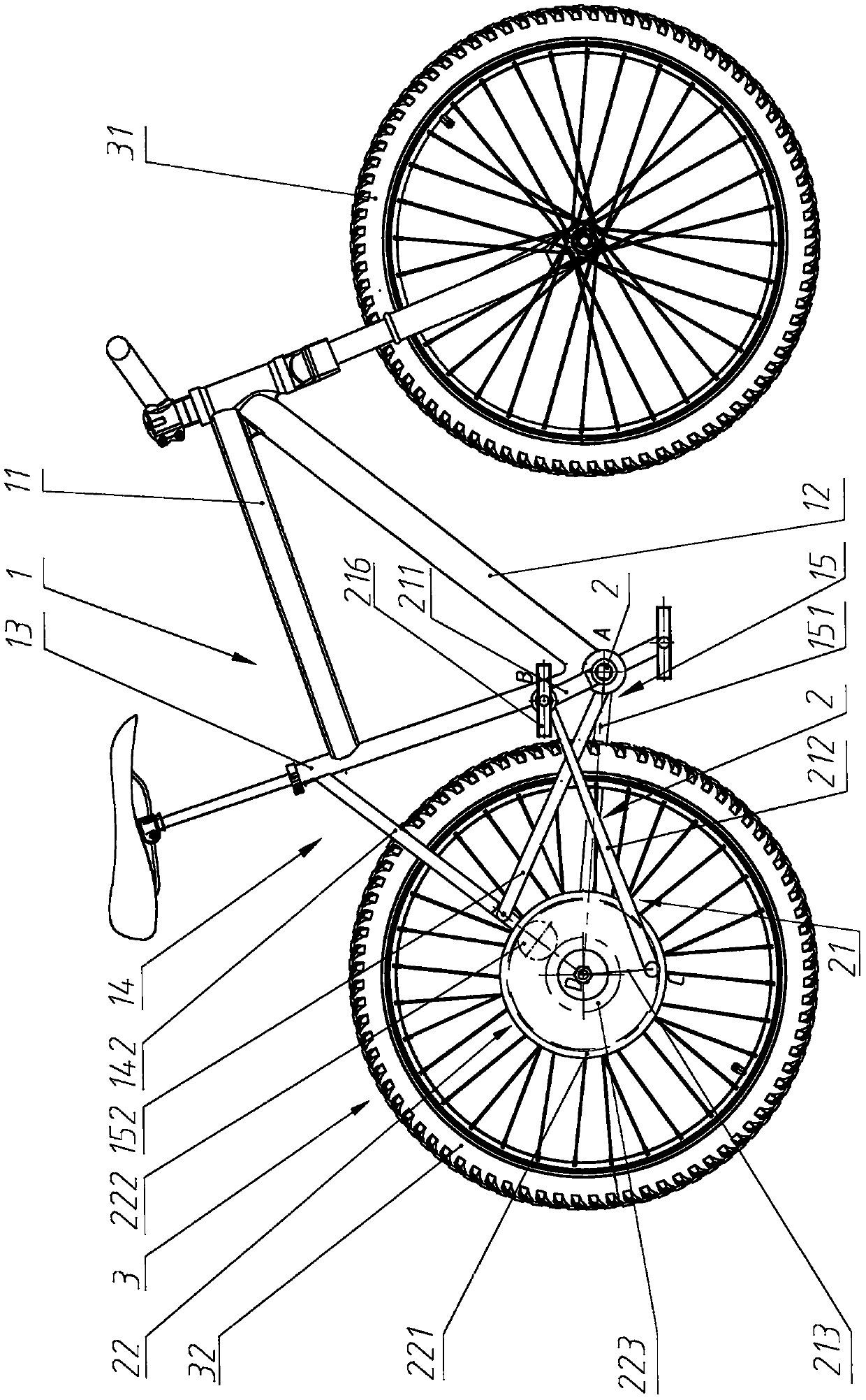

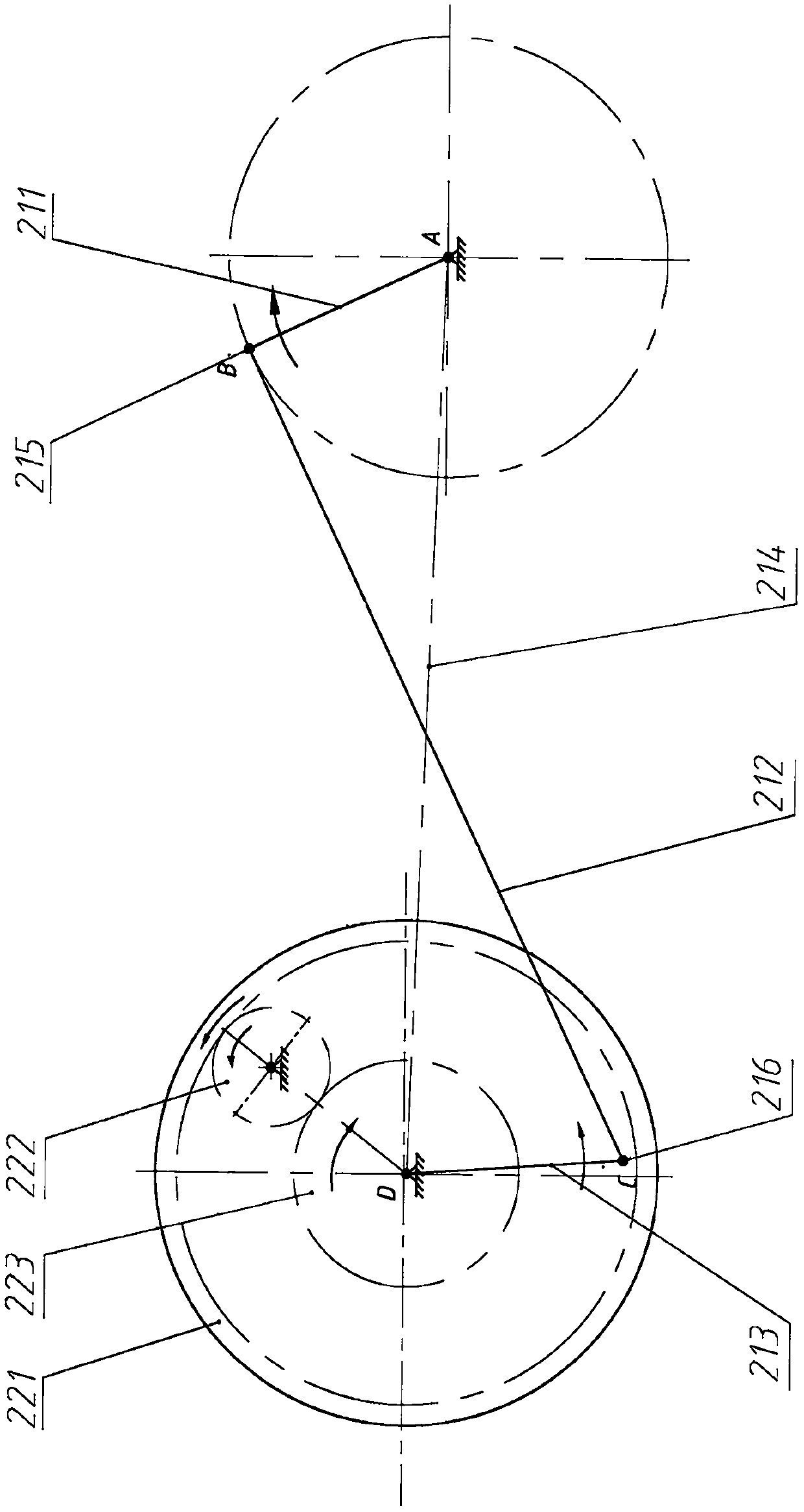

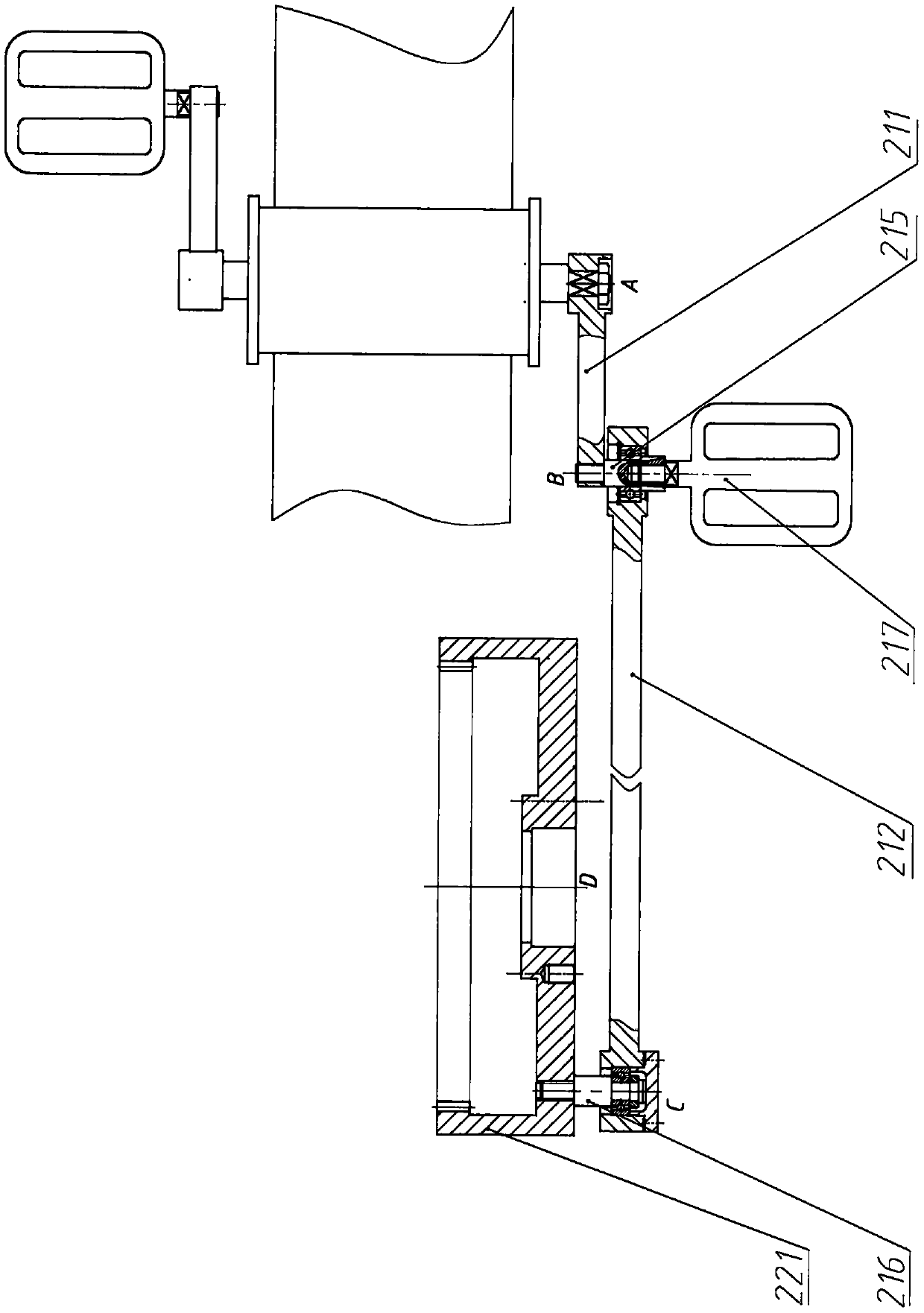

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, the present invention provides a chainless bicycle, including a frame 1, a transmission device 2 and wheels 3. The frame 1 includes an upper tube 11, a lower The pipe 12, the stand pipe 13, the seat stay 14 and the chain stay 15 are provided with a circular hole at the junction of the lower pipe 12 and the stand pipe 13, and are hinged to the outer circle of the central shaft 4. The transmission device 2 includes A reverse double crank mechanism 21 and a speed increasing and changing direction mechanism 22. The reverse double crank mechanism 21 includes a driving crank 211, a connecting rod 212, a driven crank 213, and a frame 214. The A end of the driving crank 211 A square hole is fixedly connected to the square head of the central shaft 4. The speed increasing and changing direction mechanism 22 includes an internal gear 221, an idler 222, an external gear 223 and a fixed support frame 224. The outside of the idler 222 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com