Environment-friendly coating equipment

A coating and equipment technology, applied in the directions of packaging, wrapping paper, wrapping objects, etc., can solve the problems of waste of protective film, different sizes of diaphragms, and large differences in the coating of cylindrical workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

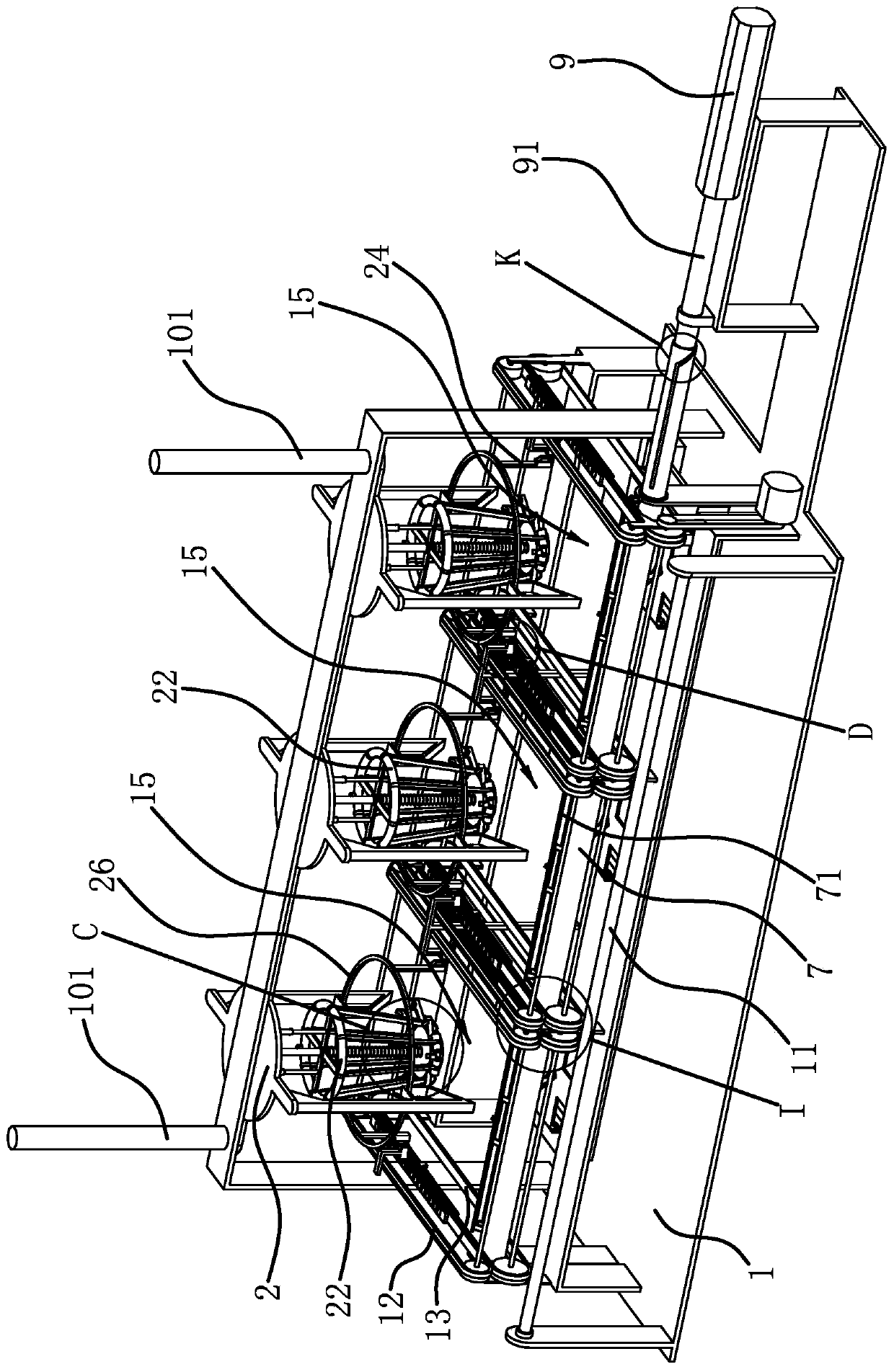

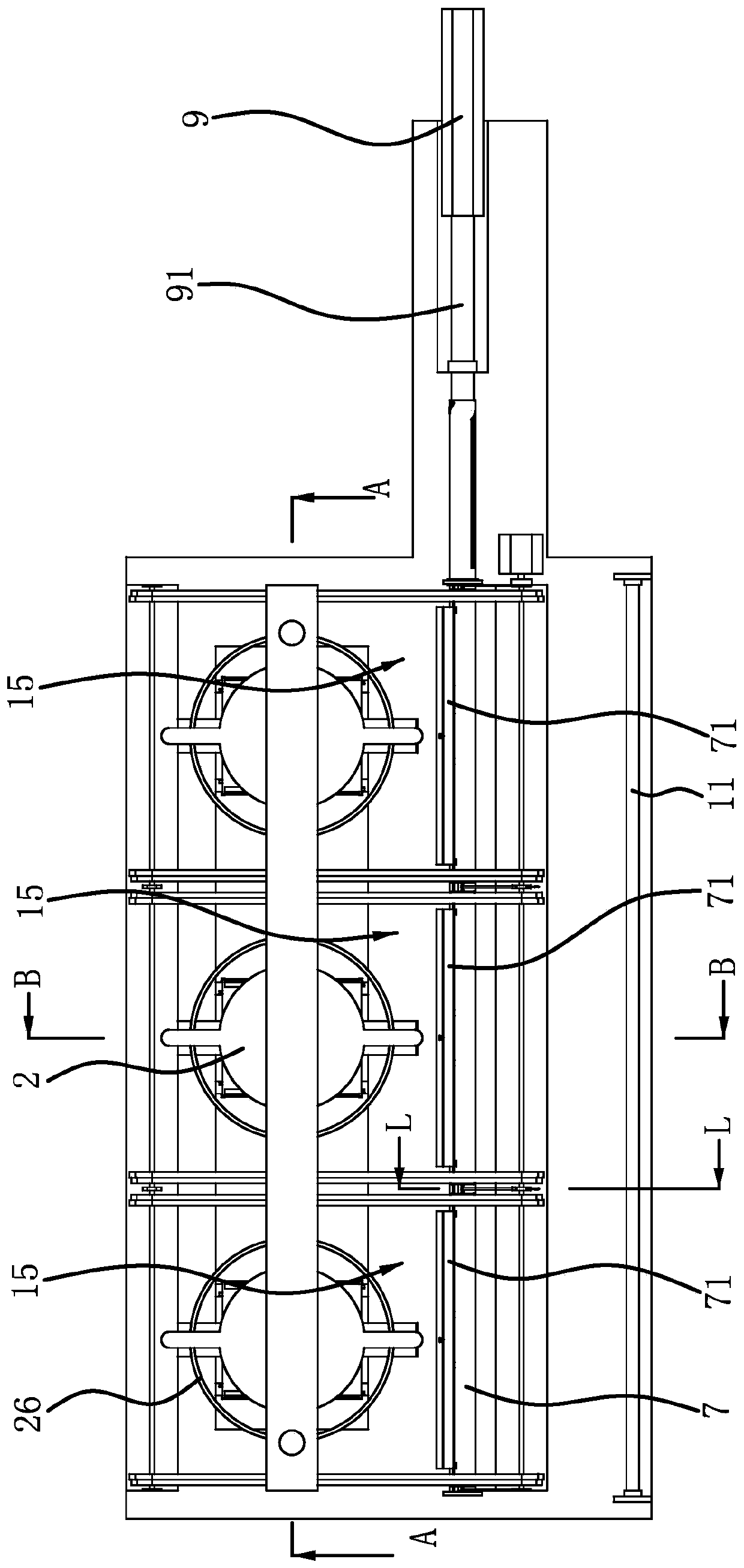

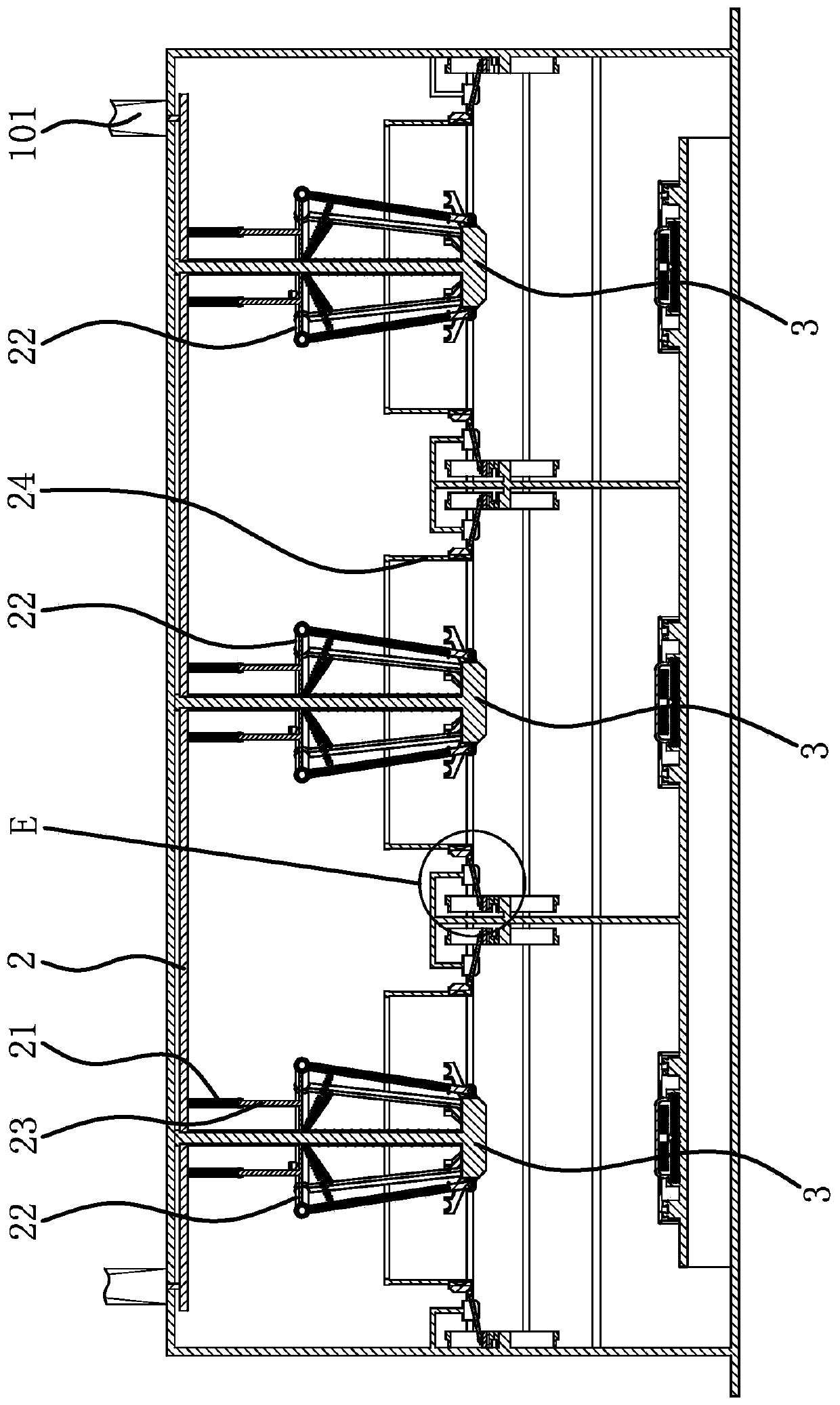

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0020] Such as Figure 1 to Figure 5As shown, a kind of environmental protection coating equipment comprises frame 1, several pairs of upper conveyor belts 12 and some pairs of lower conveyor belts 13, frame 1 includes two rows of vertically arranged support plates 16, all of which are rotatably connected with uploading links on support plates 16. The transmission wheel 122 and the lower transmission wheel 132, the upper transmission belt 12 is sleeved on the corresponding two upper transmission wheels 122, the lower transmission belt 13 is sleeved on the corresponding two lower transmission wheels 132, and the upper transmission wheels 122 of the same row are connected by the upper shaft. Fixed connection, the lower trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com