A kind of anti-blowing type high-efficiency dust collector

A reverse blowing, dust collector technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of long time for air bag movement and low dust cleaning efficiency, and achieve better dust removal effect and dust removal. High efficiency and the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

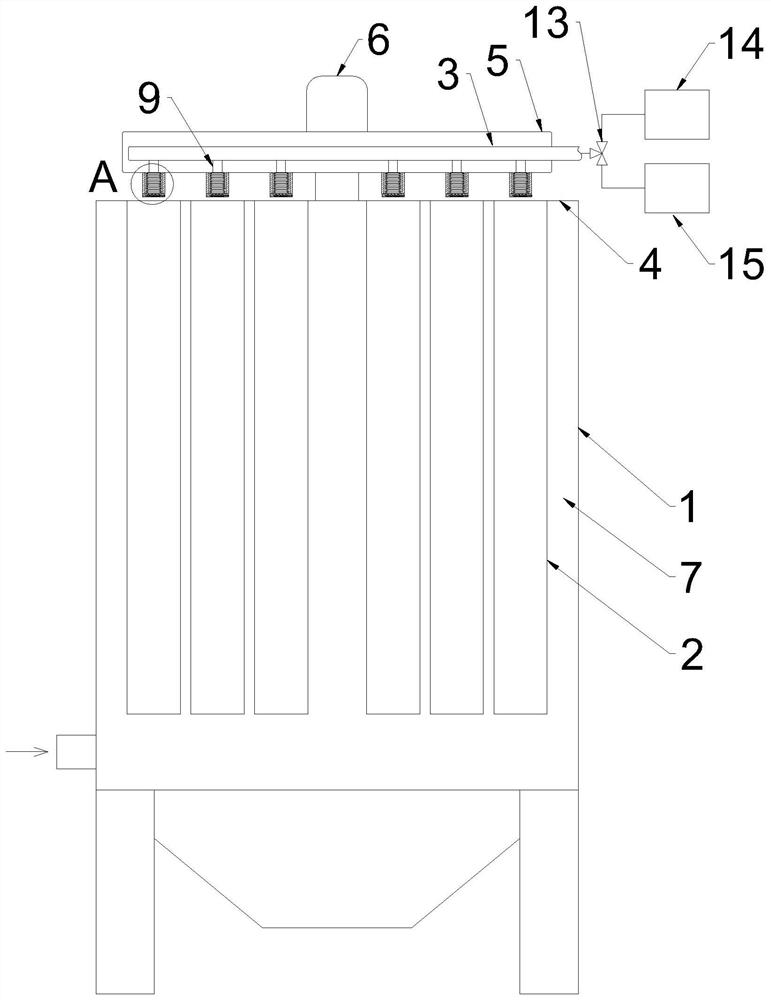

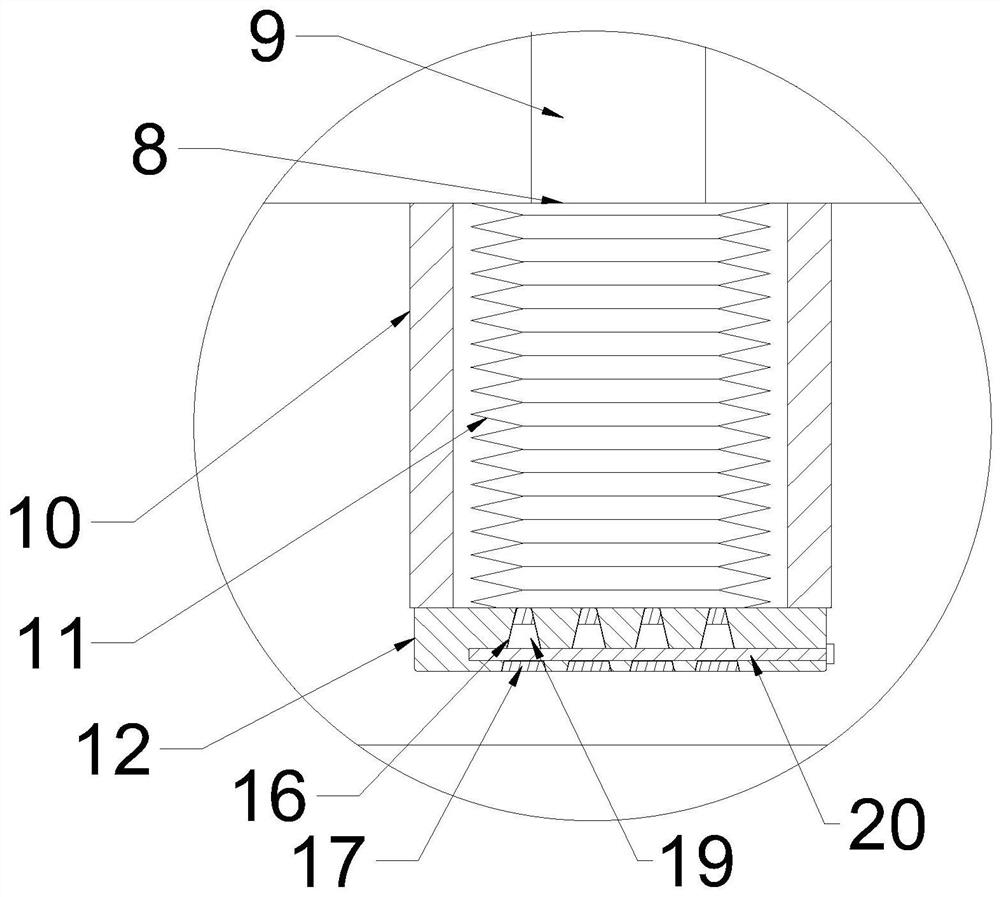

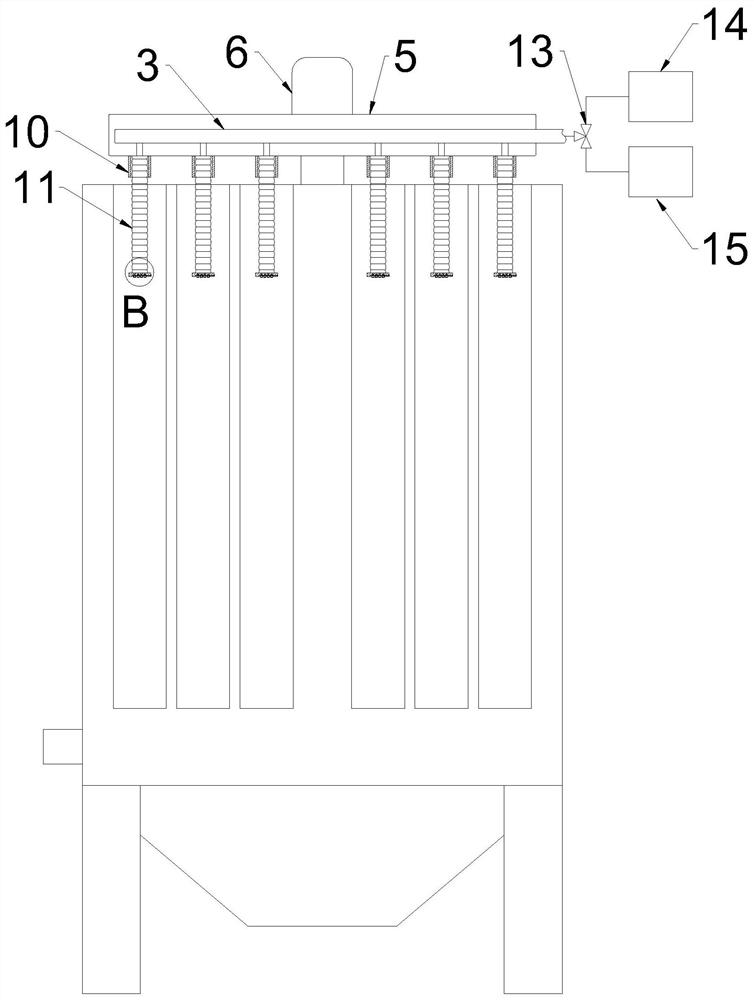

[0022] Such as figure 1 and image 3 As shown, a reverse blowing type high-efficiency dust collector includes a dust collector box 1, a filter bag 2, an air bag 3, a splitter plate 4, a rotating frame 5 and a servo motor 6.

[0023] Such as figure 1 and Figure 5 As shown, the dust collector box 1 is cylindrical, the bottom of the dust collector box 1 is provided with an air inlet, and the top is provided with an air outlet. Divider plate 4 is horizontally fixed in dust collector box 1, and divider plate 4 divides dust collector box 1 into dust removal chamber 7 and clean room (not shown in the figure) from bottom to top. Diverter plate 4 is provided with several filter bag fixing holes, and the filter bag fixing holes are arranged radially in a straight line centered on the axis of dust collector box 1; the top of filter bag 2 is installed in the filter bag fixing holes. The center of splitter plate 4 horizontally installs swivel frame 5 by rotating shaft and bearing, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com