A broken stone processing equipment for bridge engineering construction which is changed from throwing to accelerated crushing

A technology of processing equipment and bridge engineering, which is applied in the direction of grain processing, etc., can solve the problems of counterattack plate deformation, wear, strong force, etc., and achieve the effect of enhanced change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

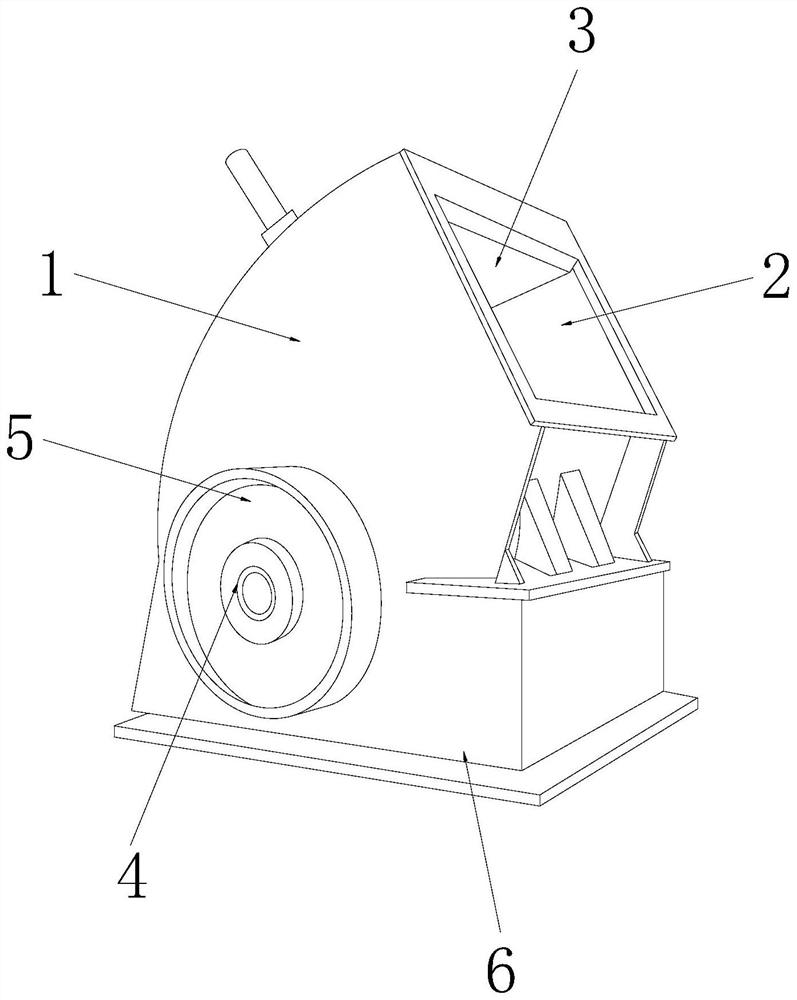

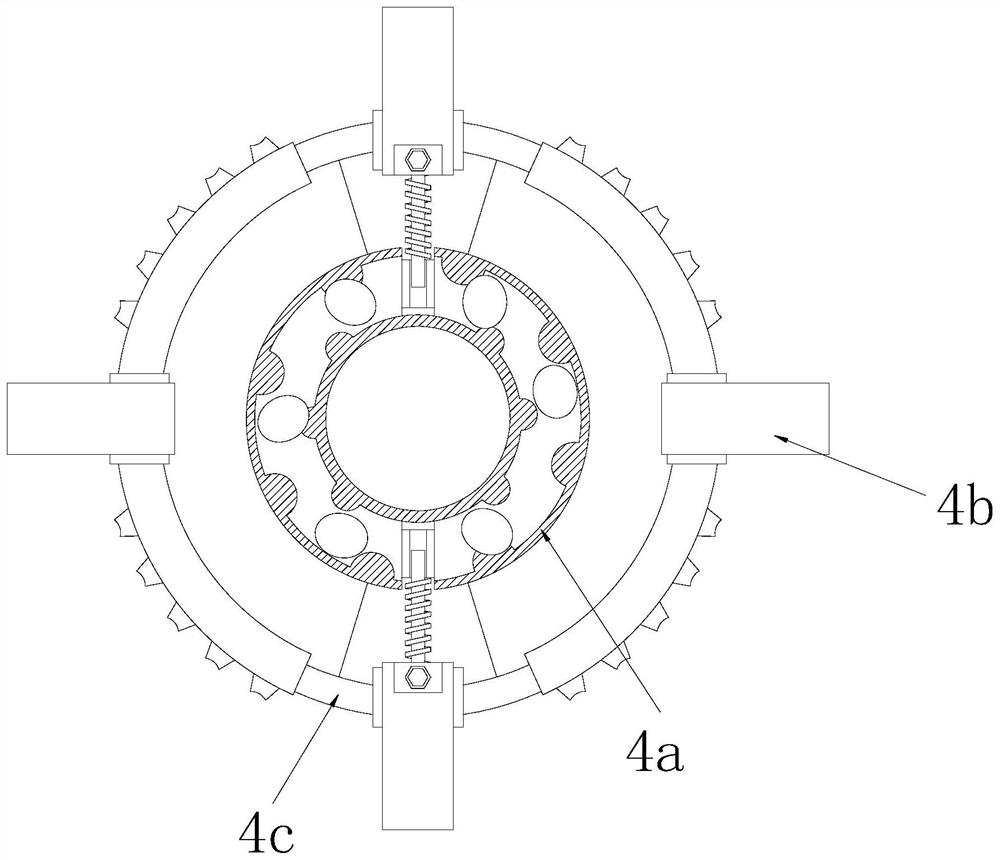

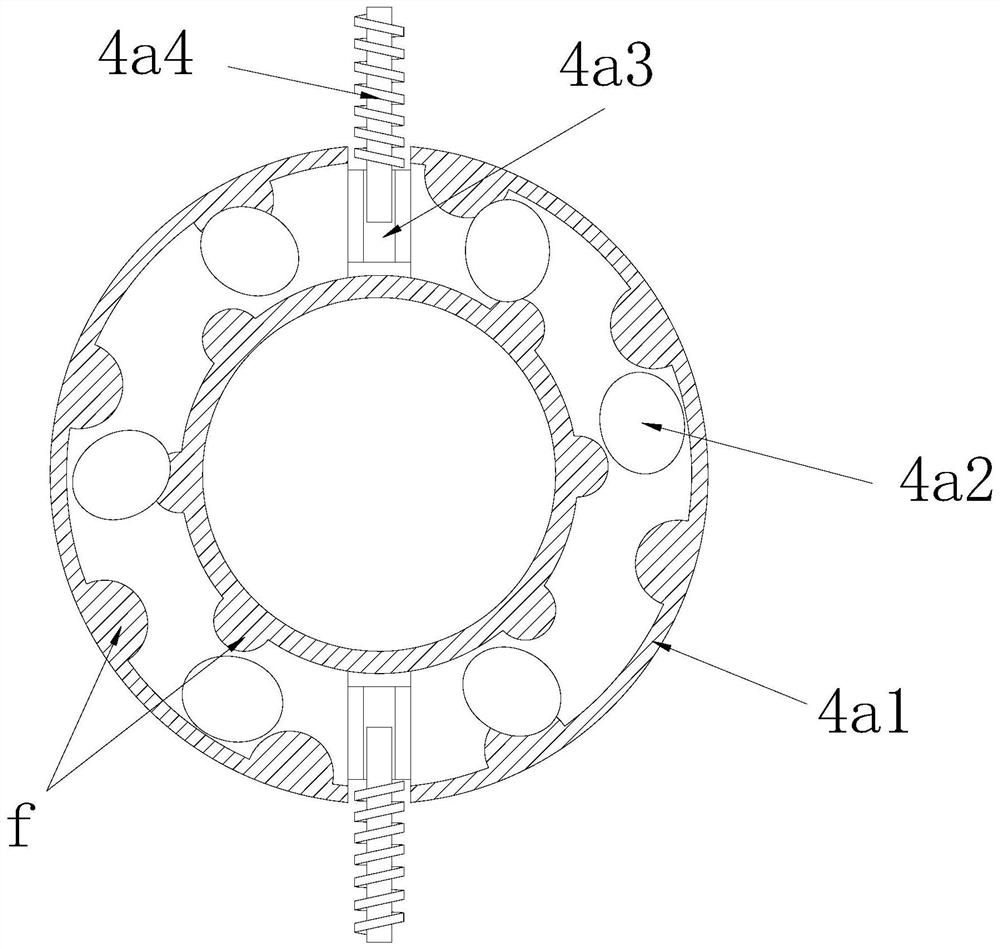

[0027] Such as Figure 1-Figure 4 As shown, the present invention provides a technical scheme of a broken stone processing equipment for bridge engineering construction that is changed to accelerated crushing by throwing:

[0028] Such as Figure 1-Figure 2 As shown, a kind of gravel processing equipment for bridge engineering construction that is changed to throwing and accelerated crushing, its structure includes a shell 1, a feed port 2, an impact plate 3, an equalization device 4, a rotor 5, and a discharge port 6. The feeding port 2 is set on the upper part of the shell 1 and is an integrated structure. The counterattack plate 3 is installed on the inner upper wall of the shell 1 and connected by a screw screw. The equalization device 4 and the rotor 5 are connected by fitting. And located in the middle of the housing 1, the rotor 5 and the housing 1 are connected by electric welding, the feeding port 6 is located on the lower surface of the housing 1 and is an integrate...

no. 2 example

[0037] Such as figure 1 , figure 2 as well as Figure 5 As shown, the present invention provides a technical scheme of a broken stone processing equipment for bridge engineering construction that is changed to accelerated crushing by throwing:

[0038] Such as Figure 1-Figure 2 As shown, a kind of gravel processing equipment for bridge engineering construction that is changed to throwing and accelerated crushing, its structure includes a shell 1, a feed port 2, an impact plate 3, an equalization device 4, a rotor 5, and a discharge port 6. The feeding port 2 is set on the upper part of the shell 1 and is an integrated structure. The counterattack plate 3 is installed on the inner upper wall of the shell 1 and connected by a screw screw. The equalization device 4 and the rotor 5 are connected by fitting. And located in the middle of the housing 1, the rotor 5 and the housing 1 are connected by electric welding, the feeding port 6 is located on the lower surface of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com