Automatic truss type spraying system facing hull sections

A technology for hulls and racks, which is applied in jetting devices, abrasive jetting machine tools, used abrasive treatment devices, etc., can solve the problems of high consumption of raw materials, low efficiency and poor quality, so as to improve the coating quality and production. Efficiency, the effect of high-precision paint film thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

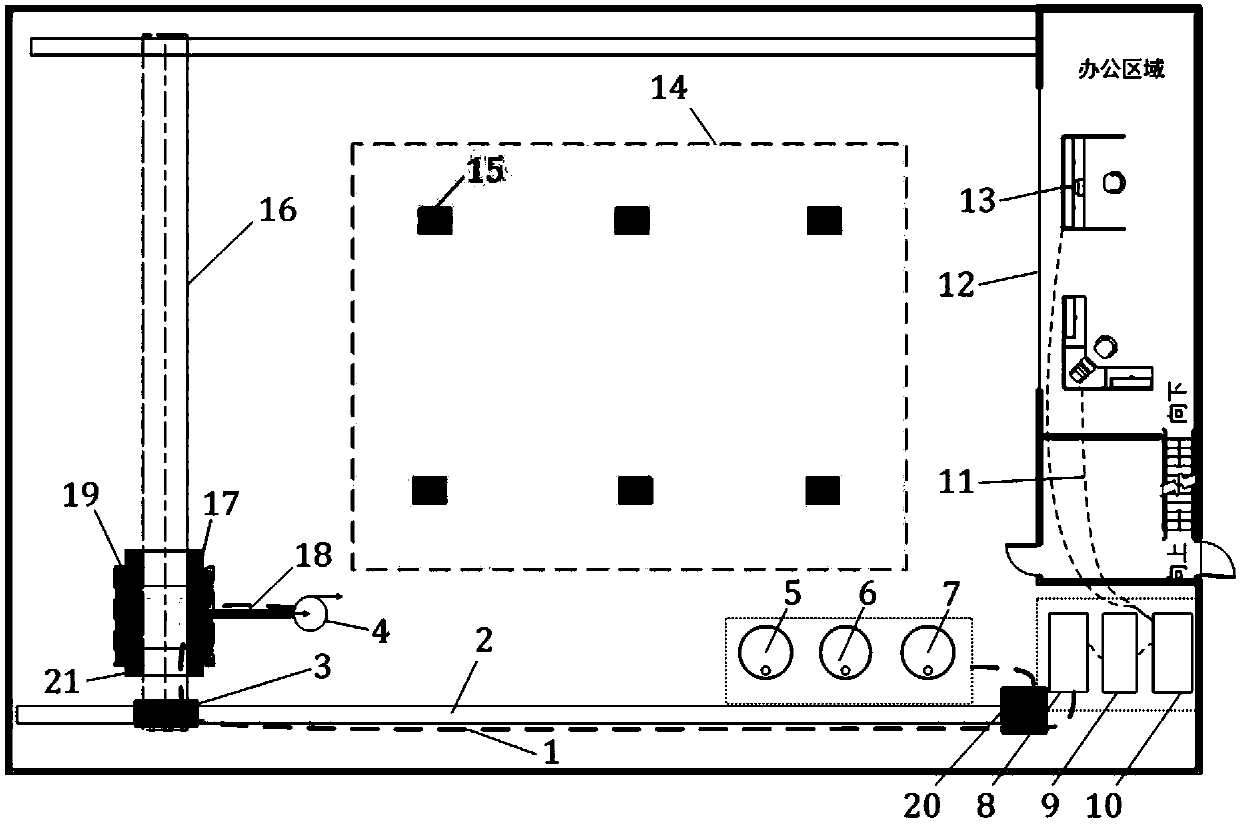

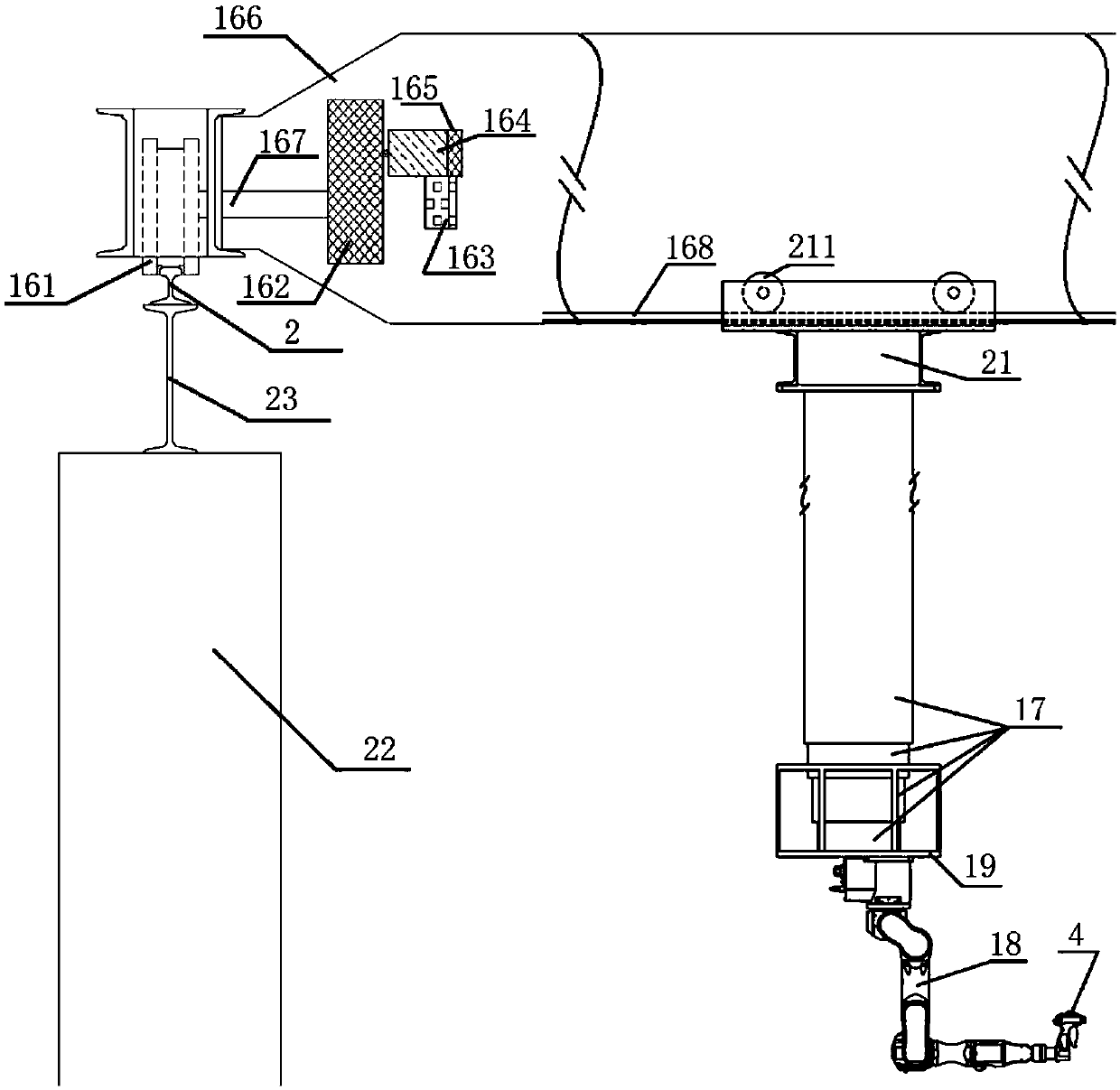

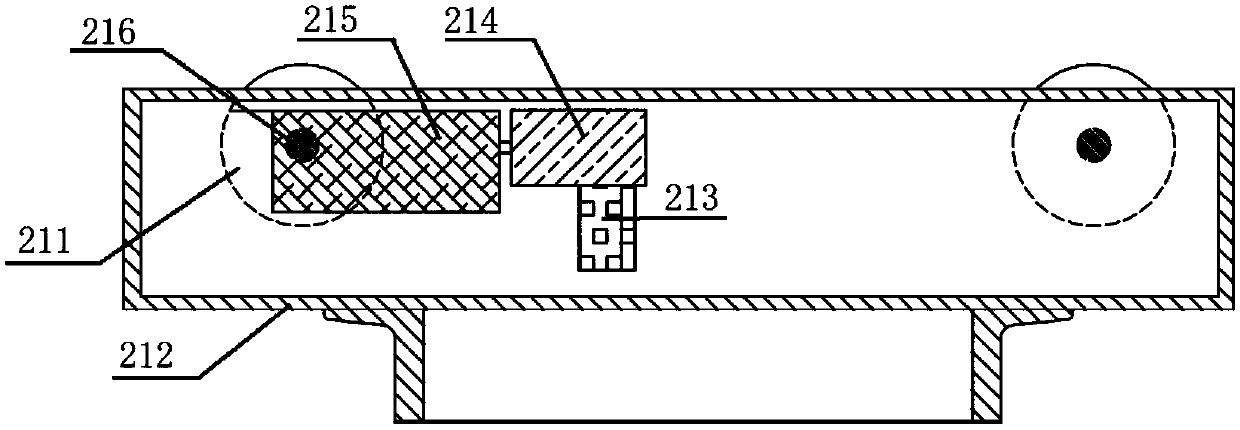

[0024] like figure 1 As shown, it is a specific application scenario of an automated rack-type spraying system for hull segmentation involved in this embodiment, which includes: the spraying workshop is divided into an office area and a spraying area, and the central control console 13 in the office area passes through the network cable 11 It is connected with the path planning module 9 and forms a local area network. The operator monitors the running status of the spraying robot through the glass monitoring window 12 and the centralized control console 13 in the office area, and controls the spraying robot. The path planning module 9 and the motion control module 8 pass through The industrial network cable is connected to transmit the motion path information of the spray gun. The output end of the motion control module 8 is connected to the electrical cabinet 10 and transmits the motion command information of each axis of the spraying robot. The electrical cabinet 10 is also u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com