Rapid positioning device for machining

A positioning device and machining technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of low production efficiency and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

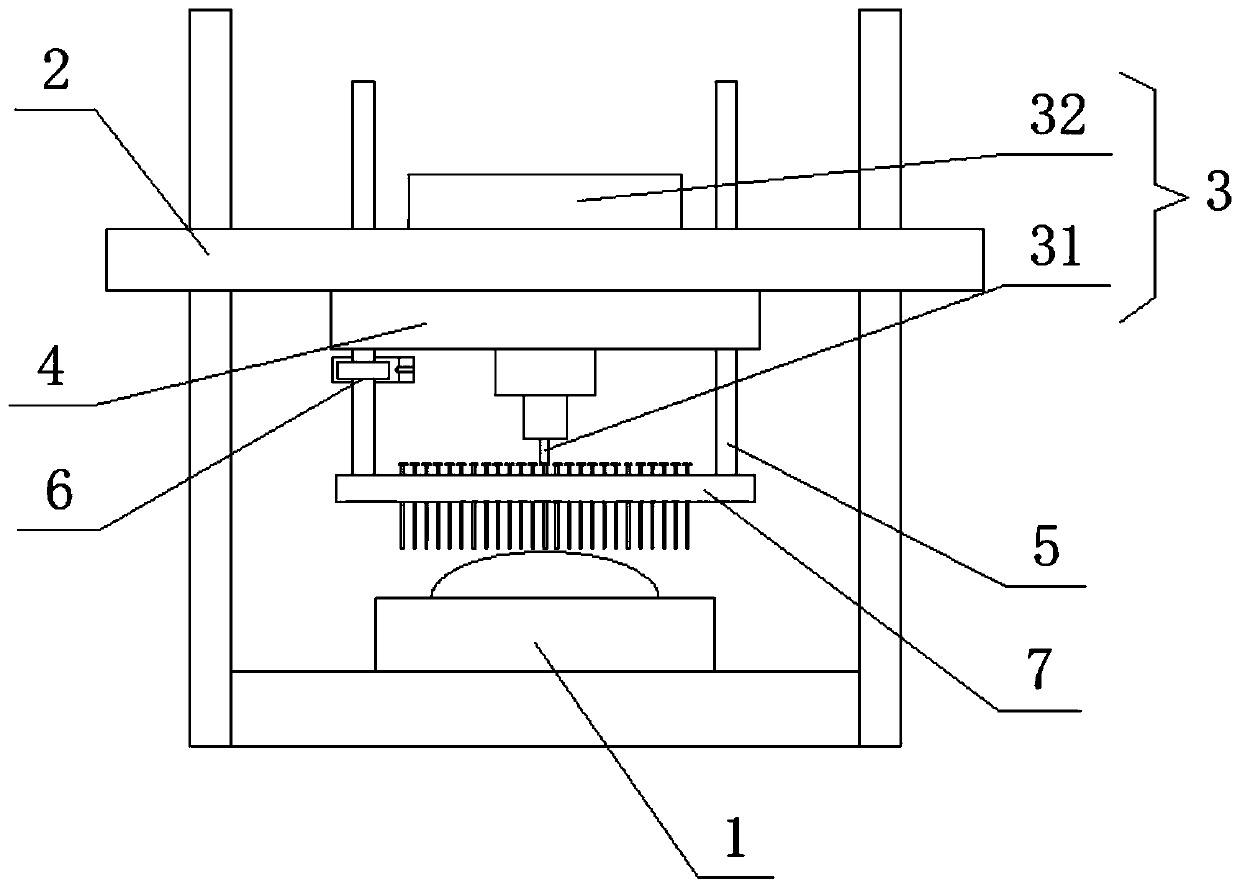

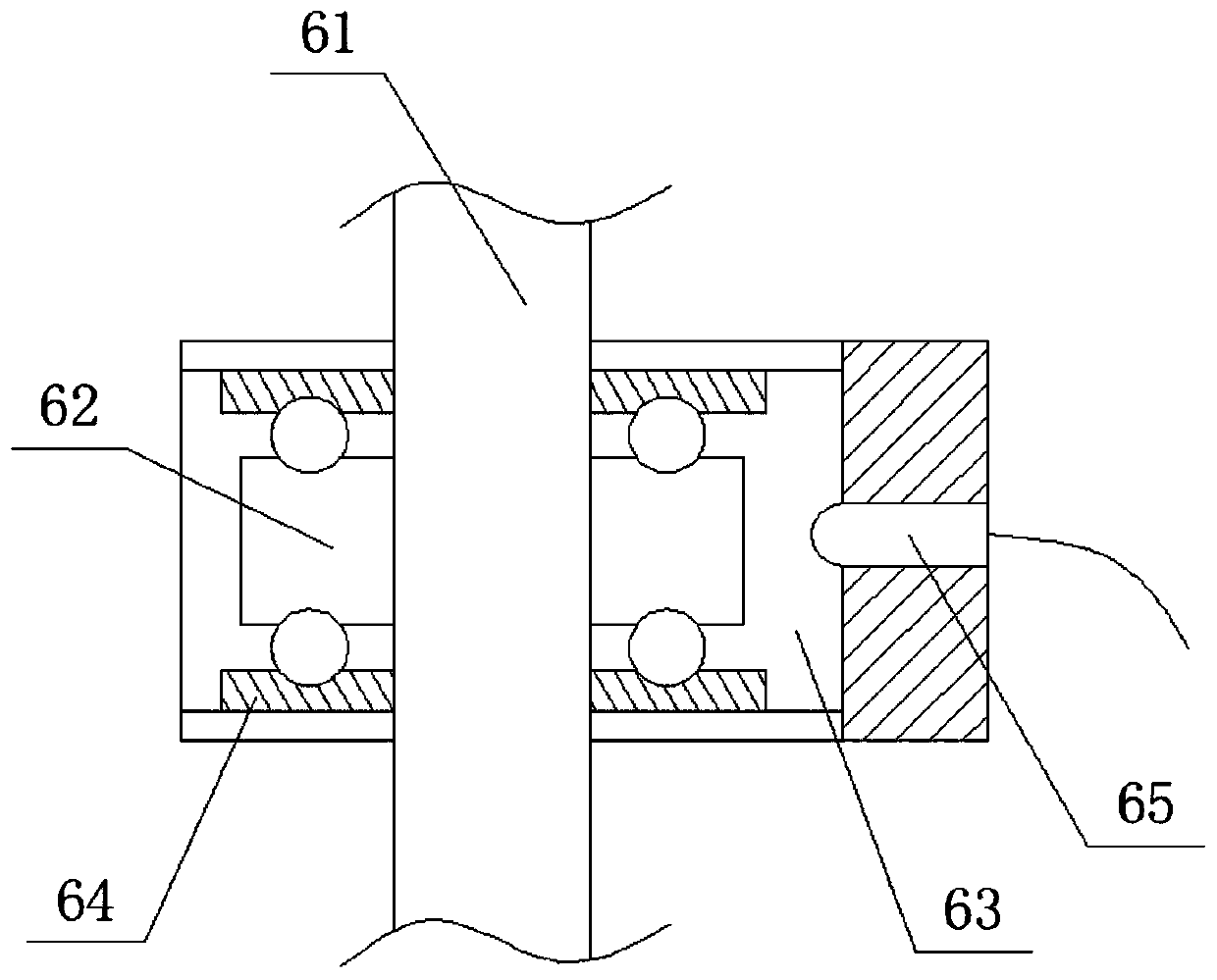

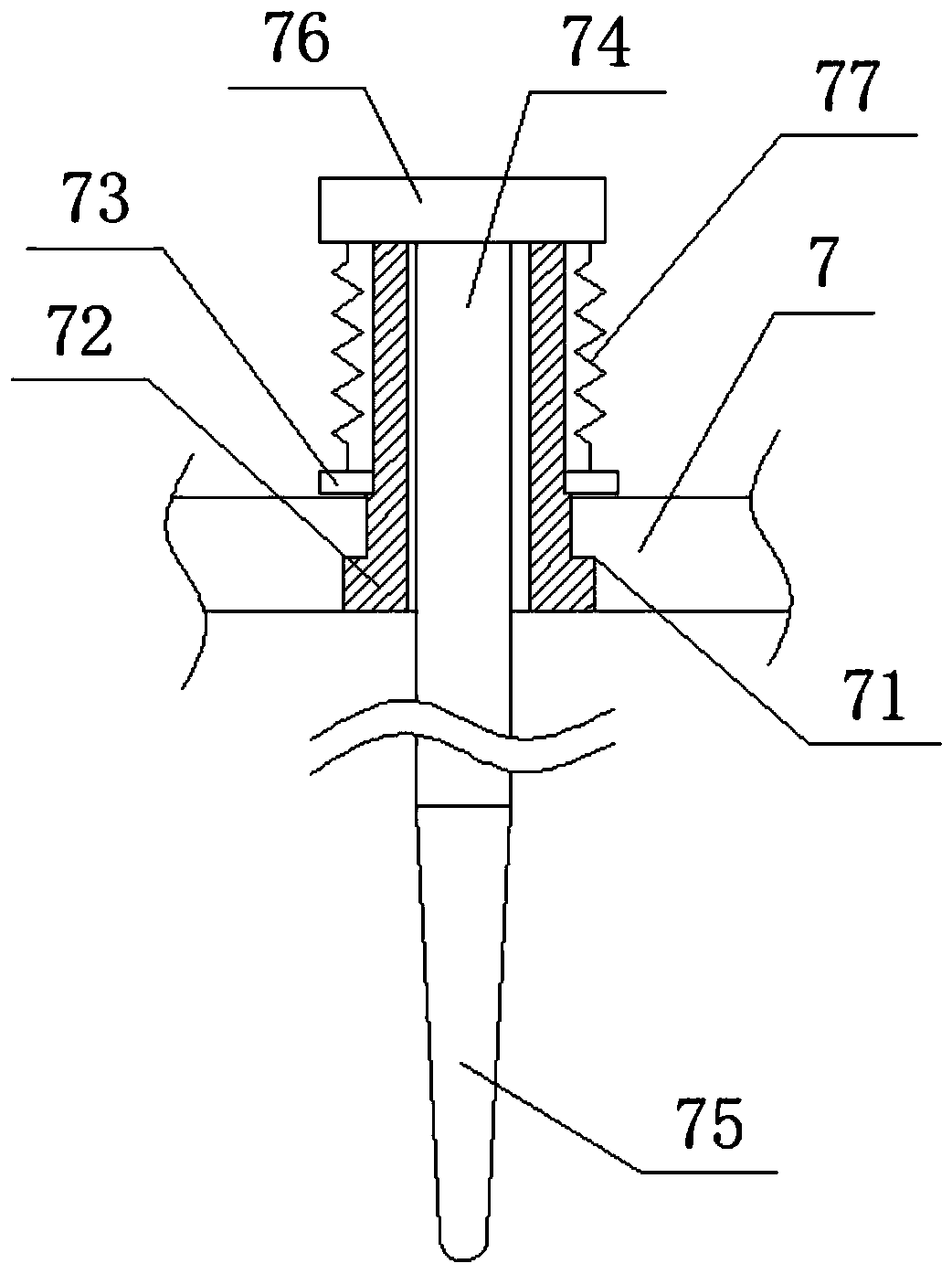

[0021] Such as Figure 1 ~ Figure 4 As shown, the rapid positioning device for machining provided in this embodiment includes a clamping table 1, a support frame 2 and a cutting system 3. The four corners of the clamping table 1 are equipped with a support frame 2, and the support frame 2 is suspended and installed with a The cutting system 3 matched with the clamping table 1, the cutting system 3 is composed of a tool 31 and a control system 32 for controlling the movement of the tool 31, an auxiliary positioning system is also provided between the cutting system 3 and the clamping table 1, the The auxiliary positioning system includes a support 4, a linear movement pair 5, a ball screw 6, a probe board 7 and a measuring system 8. The support 4 is detachably installed on the support frame 2 on one side of the cutting system 3, and the support 4 is provided with There are at least three vertically arranged linear moving pairs 5, wherein one of the linear moving pairs 5 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com