Flying knife setting device for disc chipper

A disc-type chipper and knife setting device technology, which is applied in the manufacture of veneer, wood processing equipment, manufacturing tools, etc., can solve the problem of exceeding the specified length and thickness of wood chips, inconsistent installation width B, high failure rate of wood chips, etc. problem, to achieve the effect of convenient processing, convenient tool setting and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

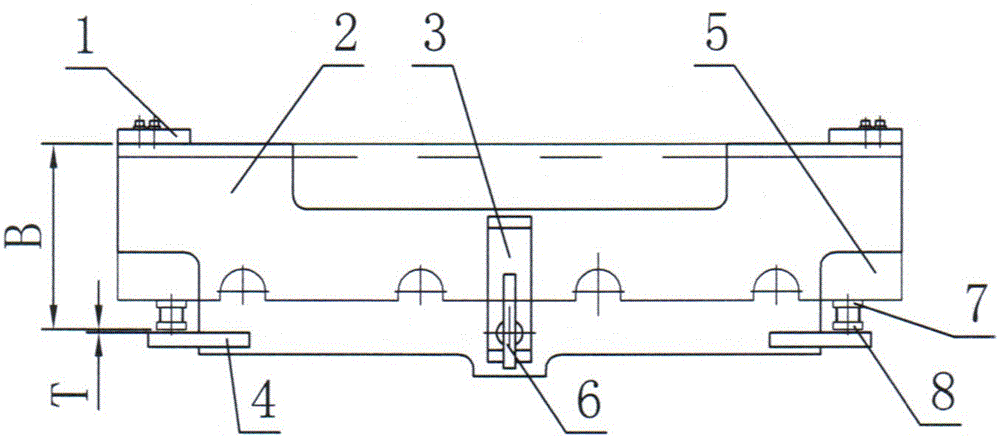

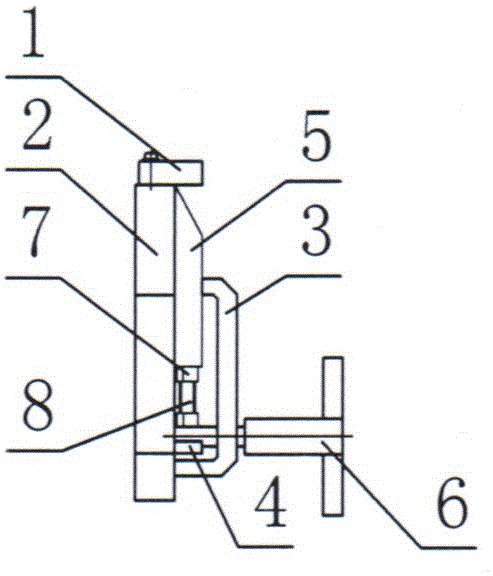

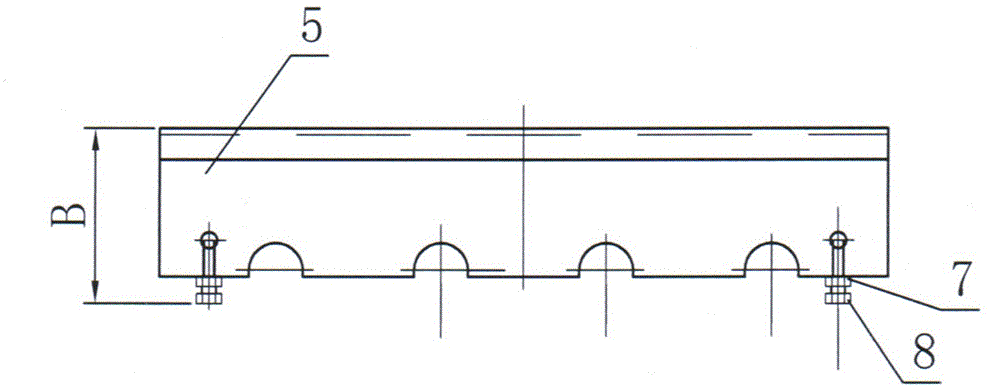

[0021] Such as Figure 1~3 As shown, a flying knife setting device for a disc chipper includes a base plate 2, a first positioning block 1 fixed on the upper side of the base plate 2, a second positioning block 4 fixed on the lower side of the base plate 2, and a A flying knife 5 between a positioning block 1 and a second positioning block 4, a knife pressing block 3 and a rotary handle 6, wherein:

[0022] ——The rotating handle 6 passes through the press block 3 and connects with the bottom plate 2, and the flying knife 5 is located between the press block 3 and the bottom plate 2;

[0023] ——The flying knife 5 is also provided with a locking nut 7 and an adjusting bolt 8. The locking nut 7 is sleeved on the adjusting bolt 8. The two adjusting bolts 8 are located on the lower side of the flying knife 5. The adjusting bolt 8 and the second positioning block 4 separation.

[0024] When dismounting, the rotating handle 6 is released, and the knife pressing block 3 will leave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com