Powder cavity subpackaging system of powder-liquid double-chamber bag

A sub-packaging system and powder chamber technology, which is applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of unable to realize powder filling and cannot guarantee the quality of powder filling, so as to improve the filling quality of powder chamber and reduce oxidation Function, effect of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

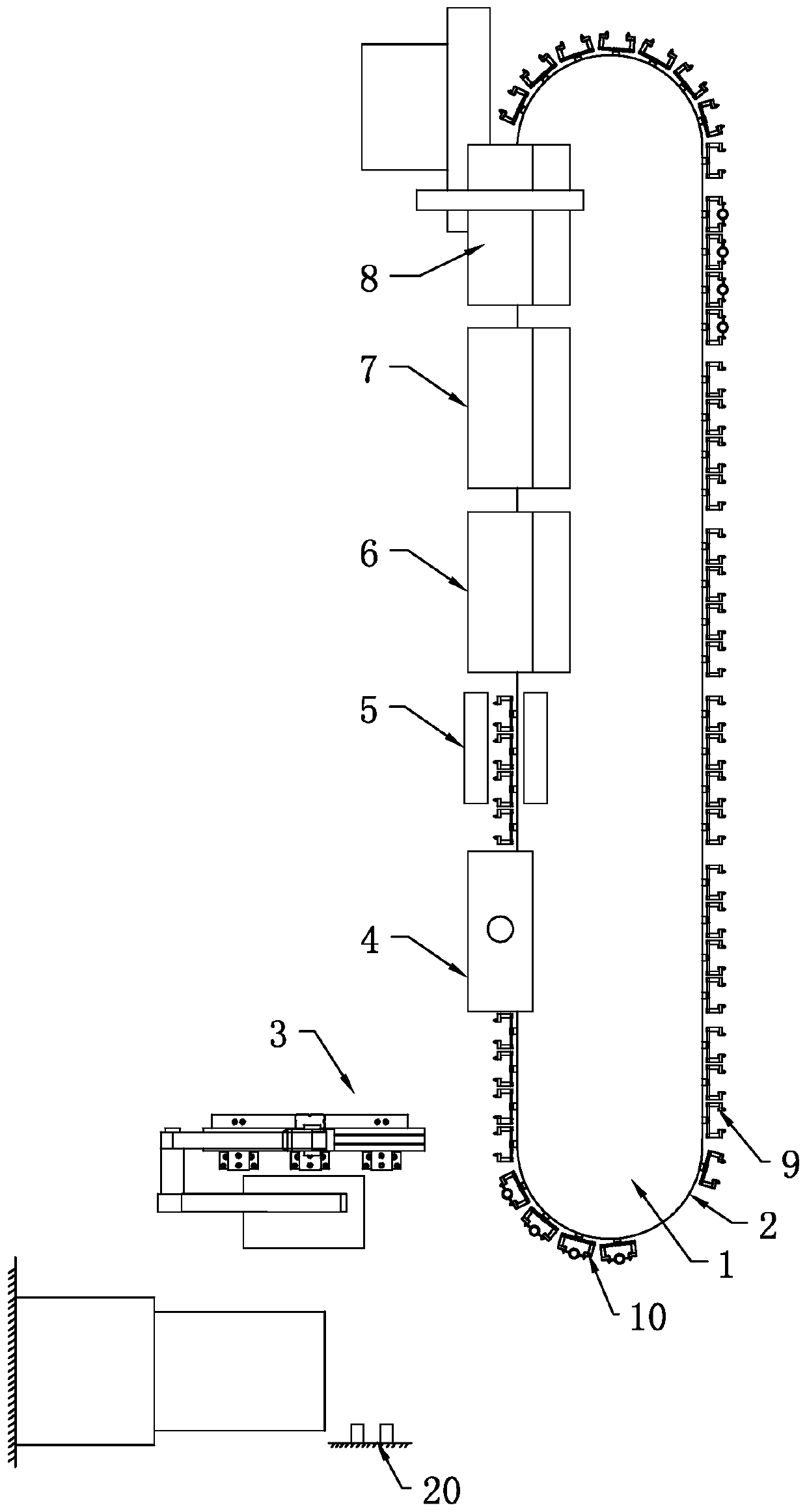

[0053] refer to figure 1 , the powder-liquid double-chamber bag has a liquid chamber and a powder chamber, the powder chamber filling is located after the liquid chamber filling, and the powder-liquid double-chamber bag after filling the liquid chamber needs to enter the light inspection station 20 for light inspection to judge Whether the liquid filling volume in the powder-liquid double-chamber bag is qualified, the powder-liquid double-chamber bag after passing the light inspection enters the powder filling system for powder filling.

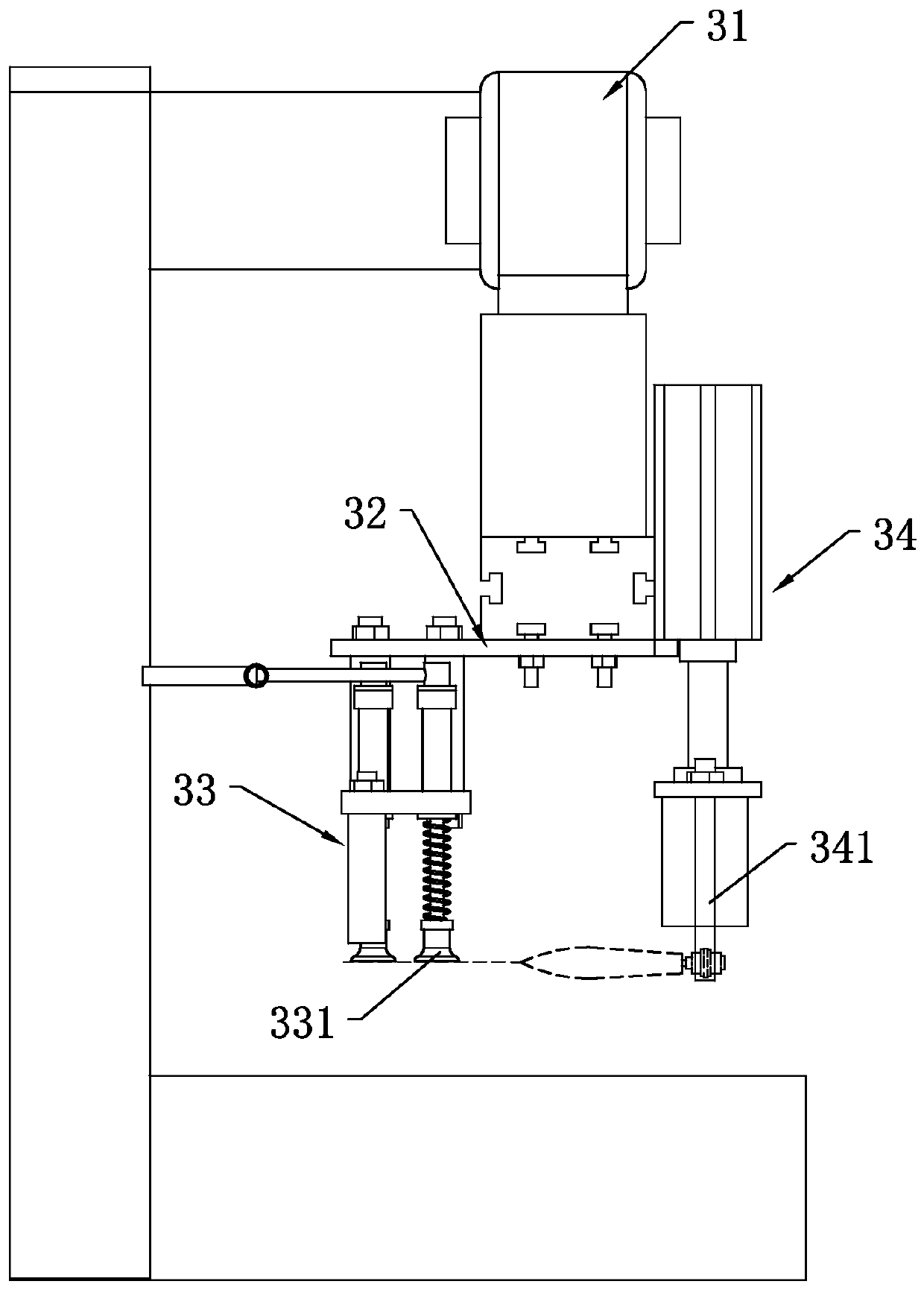

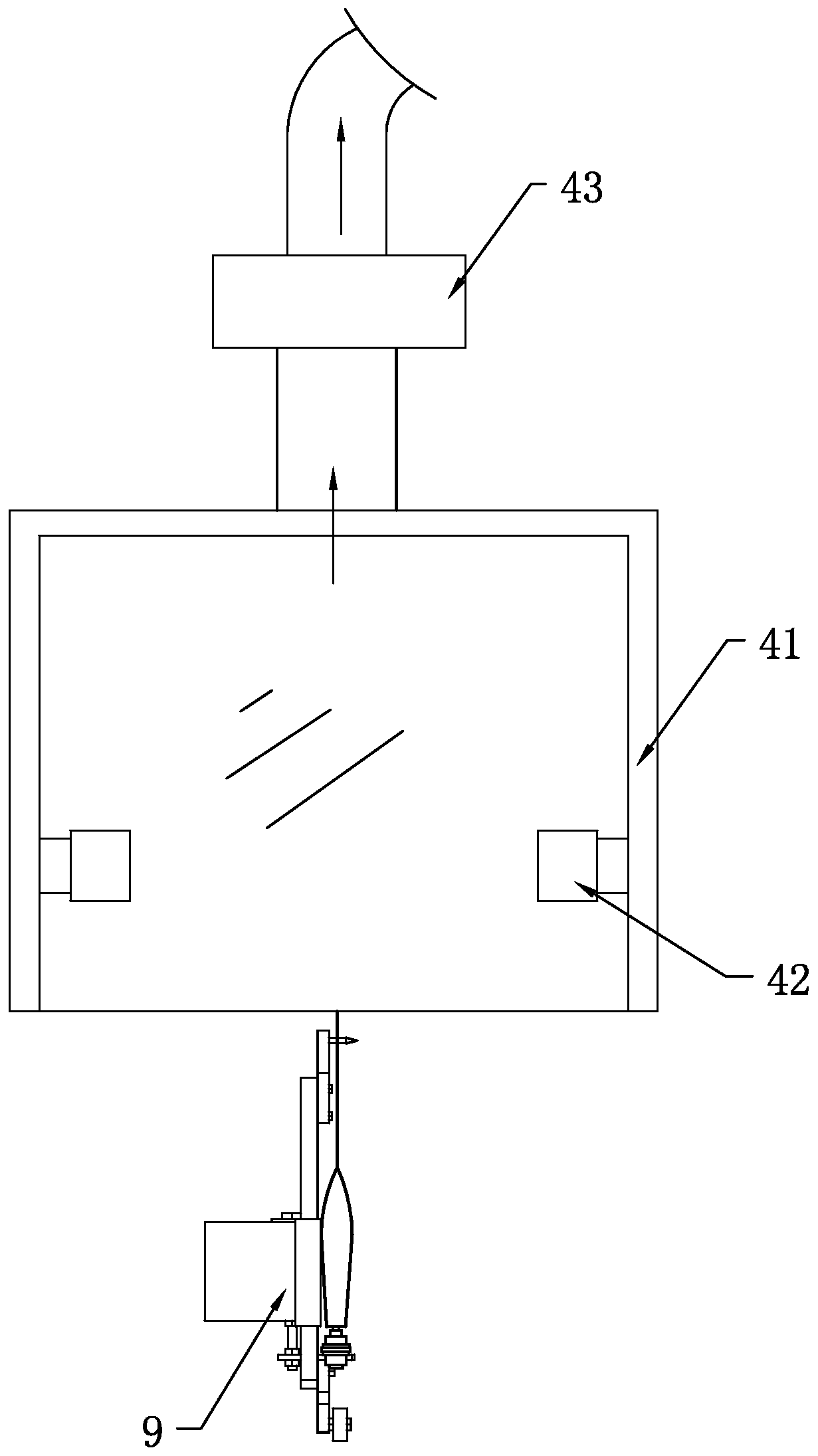

[0054] refer to figure 1 , the invention discloses a powder-liquid double-chamber bag powder chamber packing system, comprising a frame 1, a circulation conveying line 2 arranged on the frame 1, a bag hanging station 3, a bag cleaning Stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com