Settling and Separating Method of Fe Element in Aluminum Alloy Scrap Melt

A sedimentation separation, aluminum alloy technology, applied in the field of aluminum alloy melt purification, can solve problems such as low effect, achieve the effect of enhancing separability, solving low sedimentation efficiency, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

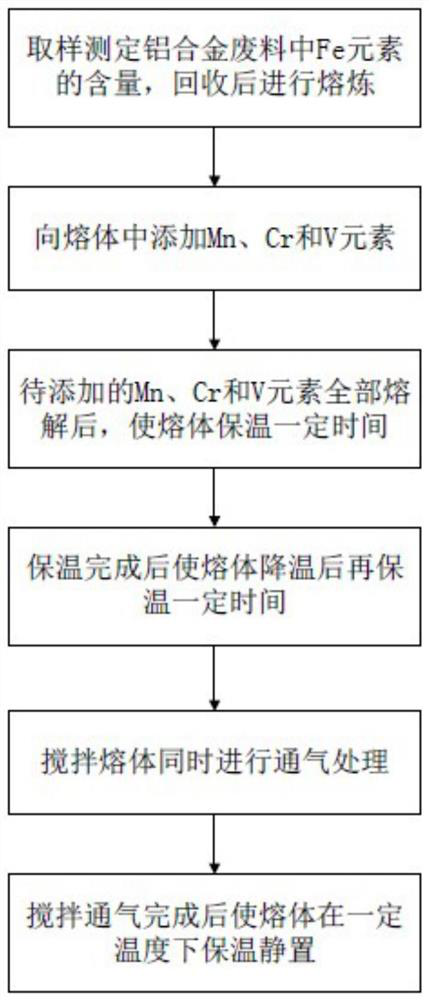

Method used

Image

Examples

Embodiment 1

[0036] Taking the aluminum alloy waste whose mass ratio of Fe impurity elements is 0.2% as an example, the aforementioned sedimentation separation method is carried out, wherein the specific mass percentages of the alloy are: Si 7%, Mg 0.6%, Cu≤0.3; Fe 0.2%; Zn ≤0.3%; Ti≤0.2%; the rest is Al. The sedimentation separation method comprises the following steps:

[0037] S1. Sampling and measuring the content of Fe element in the aluminum alloy scrap, melting after recovery, and controlling the temperature of the melt at 700°C;

[0038] S2. According to the content of Fe element in the aluminum alloy scrap, add Mn, Cr and V elements to the melt according to a certain mass ratio of Mn:Fe, Cr:Fe, V:Fe; the mass of the added Mn element and Fe element The ratio is 1, the mass ratio of added Cr element to Fe element is 0.5, and the mass ratio of added V element to Fe element is 0.2;

[0039] S3. After all the Mn, Cr and V elements to be added are melted, keep the alloy melt at 780° C...

Embodiment 2

[0051] Taking the aluminum alloy waste whose mass ratio of Fe impurity elements is 0.5% as an example, the aforementioned sedimentation separation method is carried out, wherein the specific composition mass percentages of the alloy are: Si 9%, Mg≤0.1%, Cu≤0.3; Fe 0.5%; Zn≤0.3%; Ti≤0.2%; the rest is Al. The sedimentation separation method comprises the following steps:

[0052] S1. Take a sample to measure the content of Fe in the aluminum alloy scrap, and melt it after recovery, and control the temperature of the melt at 750°C;

[0053] S2. According to the content of Fe element in the aluminum alloy scrap, add Mn, Cr and V elements to the melt according to a certain mass ratio of Mn:Fe, Cr:Fe, V:Fe; the mass of the added Mn element and Fe element The ratio is 2, the mass ratio of added Cr element to Fe element is 2, and the mass ratio of added V element to Fe element is 1;

[0054] S3. After all the Mn, Cr and V elements to be added are melted, keep the alloy melt at 810° ...

Embodiment 3

[0066] Taking the aluminum alloy waste whose mass ratio of Fe impurity elements is 1% as an example, the aforementioned sedimentation separation method is carried out, wherein the specific mass percentages of the alloy are: Si 11%, Mg 0.3%, Cu≤0.3, Fe 1%, Zn ≤0.3%, Ti≤0.2%, and the rest is Al. The sedimentation separation method comprises the following steps:

[0067] S1. Take a sample to measure the content of Fe in the aluminum alloy scrap, and melt it after recovery, and control the temperature of the melt at 820°C;

[0068] S2. According to the content of Fe element in the aluminum alloy scrap, add Mn, Cr and V elements to the melt according to a certain mass ratio of Mn:Fe, Cr:Fe, V:Fe; the mass of the added Mn element and Fe element The ratio is 5, the mass ratio of the added Cr element to the Fe element is 4, and the mass ratio of the added V element to the Fe element is 4;

[0069] S3. After all the Mn, Cr and V elements to be added are melted, keep the alloy melt at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com