Miniature nitrogen-filled airtight vacuum control device

A technology of vacuum control and nitrogen filling, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, etc. It can solve the problems of complex structure, large volume, high cost, etc., and achieve small structure size , reliable control and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

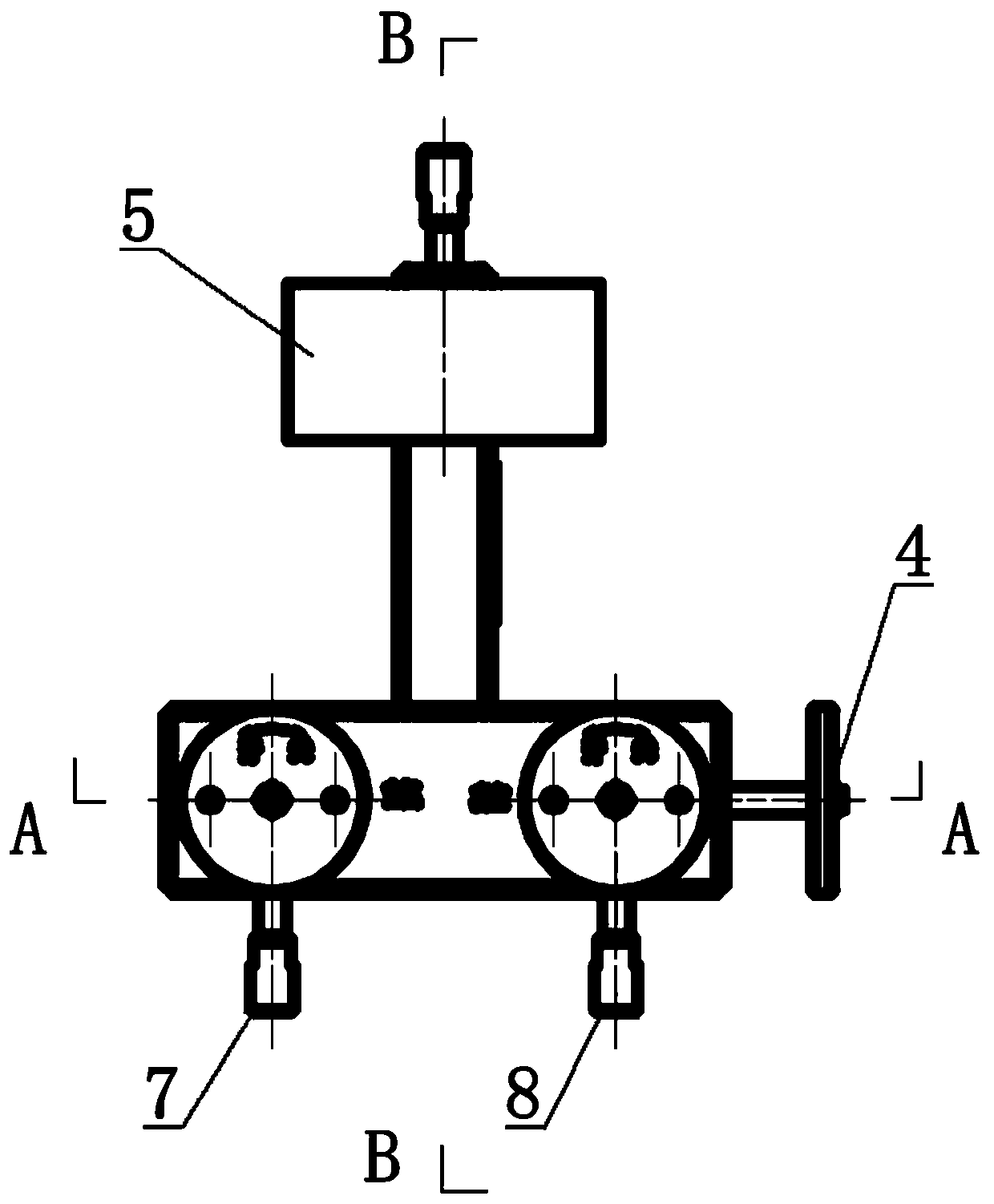

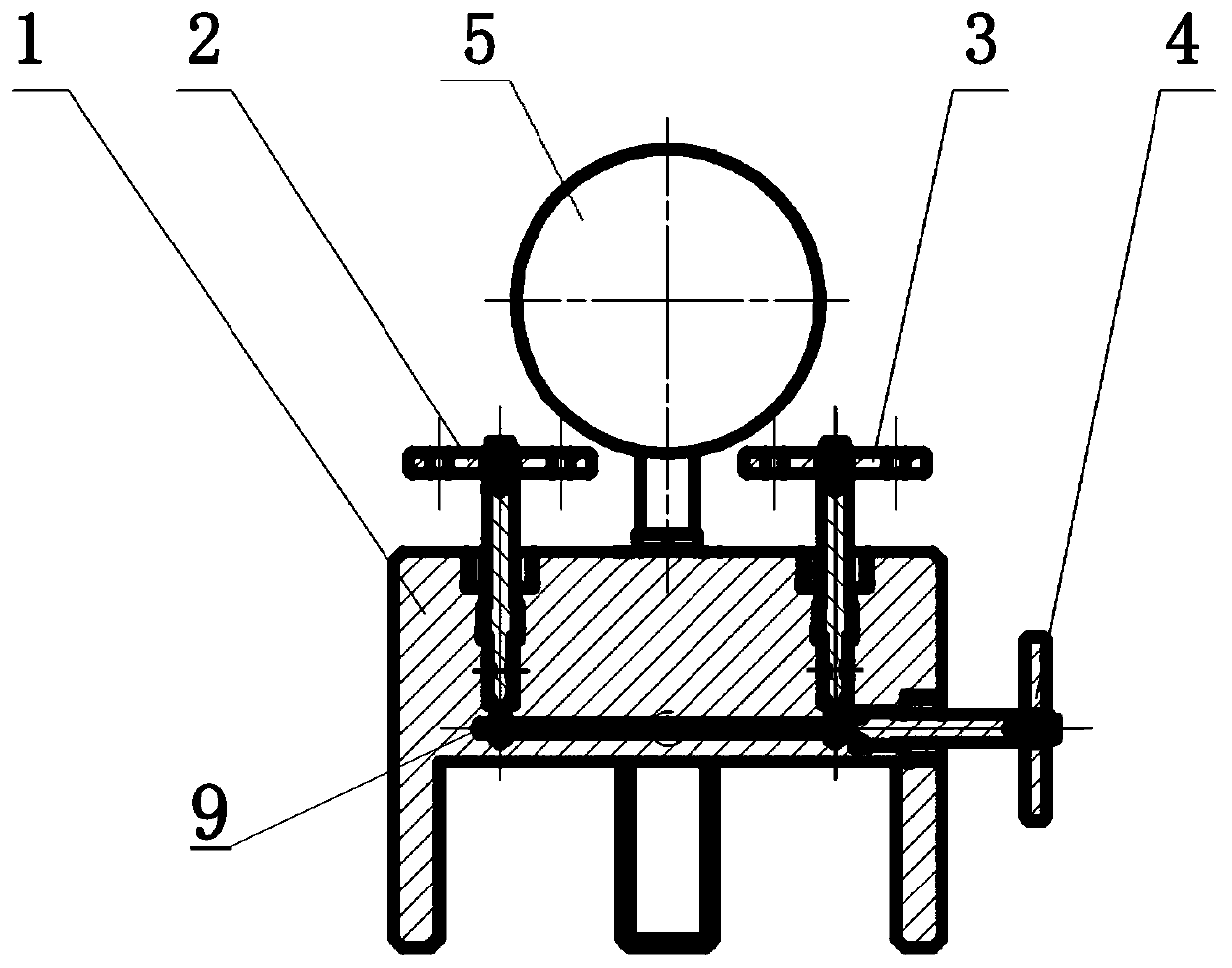

[0018] The miniature nitrogen-filled airtight vacuum control device includes an installation base 1, and the installation base 1 is provided with a ventilation channel 9, and the front left side of the ventilation channel 9 leads out from the installation base 1. There is a nitrogen filling valve 2, the front right side of the ventilation channel leads out of the installation base 1, and a vacuum adapter 8 is provided at the vacuum adapter 8, and a vacuum valve 3 is provided at the vacuum adapter 8, and the rear of the ventilation channel 9 exits the installation base 1, and a product adapter is provided 6. A pressure vacuum gauge 5 is provided above the ventilation passage 9 of the product adapter 6, and an exhaust valve 4 is provided at the right end of the ventilation passage 9 leading out of the installation base 1.

[0019] In the specific implementation process, the overall structure size is 276×218×262 (length×width×height), and the weight does not exceed 12kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com