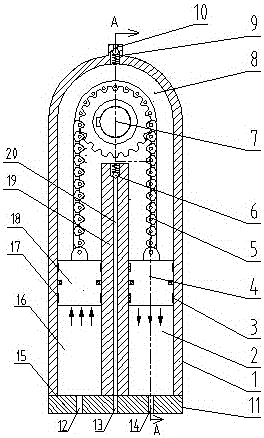

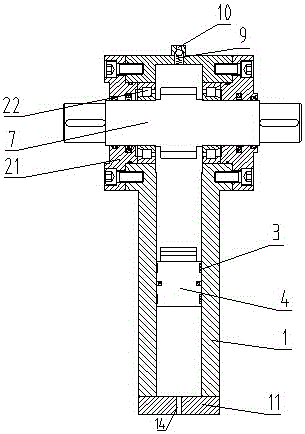

Large-torque U-shaped hydraulic slewing mechanism

A technology of slewing mechanism and high torque, applied in the direction of fluid pressure actuating device, etc., can solve the problems of large axial structure size, unusable installation space, limited promotion, etc., and achieve the effect of small shape and structure size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] Embodiment: The high-torque U-shaped hydraulic slewing mechanism as shown in the figure includes a cylinder body 1, which is U-shaped with an opening downward. The upper end of the cylinder body 1 is provided with an exhaust hole 10 for exhausting A one-way valve 9 for deflation is provided at the hole 10 . The upper part of the cylinder body 1 is a hydraulic oil chamber 8, the two ends of the hydraulic oil chamber 8 are provided with end caps 21, and the end caps 21 are provided with bearings 22, and a rotary shaft 7 is installed between the bearings 22, and the rotary shaft The middle part of 7 is sprocket. A partition 19 is arranged in the middle of the lower part in the cylinder body 1, and an oil inlet passage 20 is arranged in the middle of the partition 19. The lower end of the oil inlet passage 20 is an oil inlet hole 13, and the upper end of the oil inlet passage 20 is located at the hydraulic pressure. An oil discharge hole is arranged in the oil chamber 8 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com