Combined hoisting device for generator stator

A technology of generator stator and hoisting device, which is applied to cranes, transportation and packaging, walking bridge cranes, etc., can solve the problem of high transportation and installation costs, and achieve the effects of simple tools, easy transportation, and small size and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

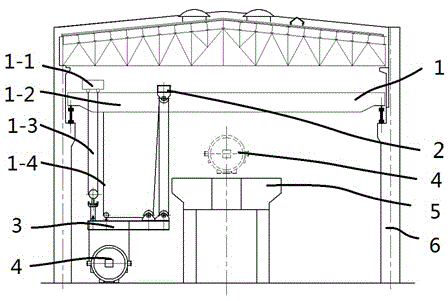

[0016] like figure 1 , 2 , 3, and 4, a generator stator 4 joint hoisting device of the present invention adopts the existing bridge crane 1 technology and transforms it, and utilizes the hoisting device to hoist more than the maximum rated lifting capacity of the bridge crane 1 generator stator 4.

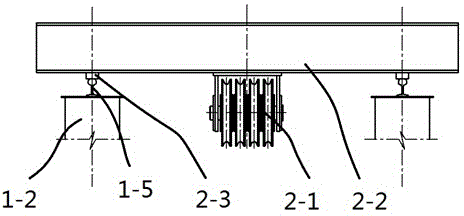

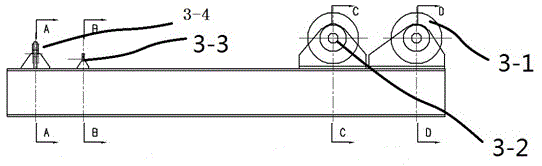

[0017] Its specific structure comprises bridge crane 1, and bridge crane 1 comprises two main girders 1-2 and auxiliary hook reel, and is provided with main hook reel and driving motor across between two main girders 1-2. The trolley 1-1, a sky beam 2 that can move along the main beam 1-2 is also straddled between the two main beams 1-2, the sky beam 2 includes a cross beam 2-2, the sky beam 2 and the lifting trolley 1-1 Connecting rods are connected between them, the upper fixed pulley block 2-1 is arranged at the bottom of the sky beam 2, the pole beam 3 is horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com