Check method for single-core cable of road illumination system

A lighting system and cable technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of increasing the labor cost of insulation recovery materials at the stripping joint of cables, inability to intuitively judge, and cable leakage, etc. The effect of construction cost, low cost and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

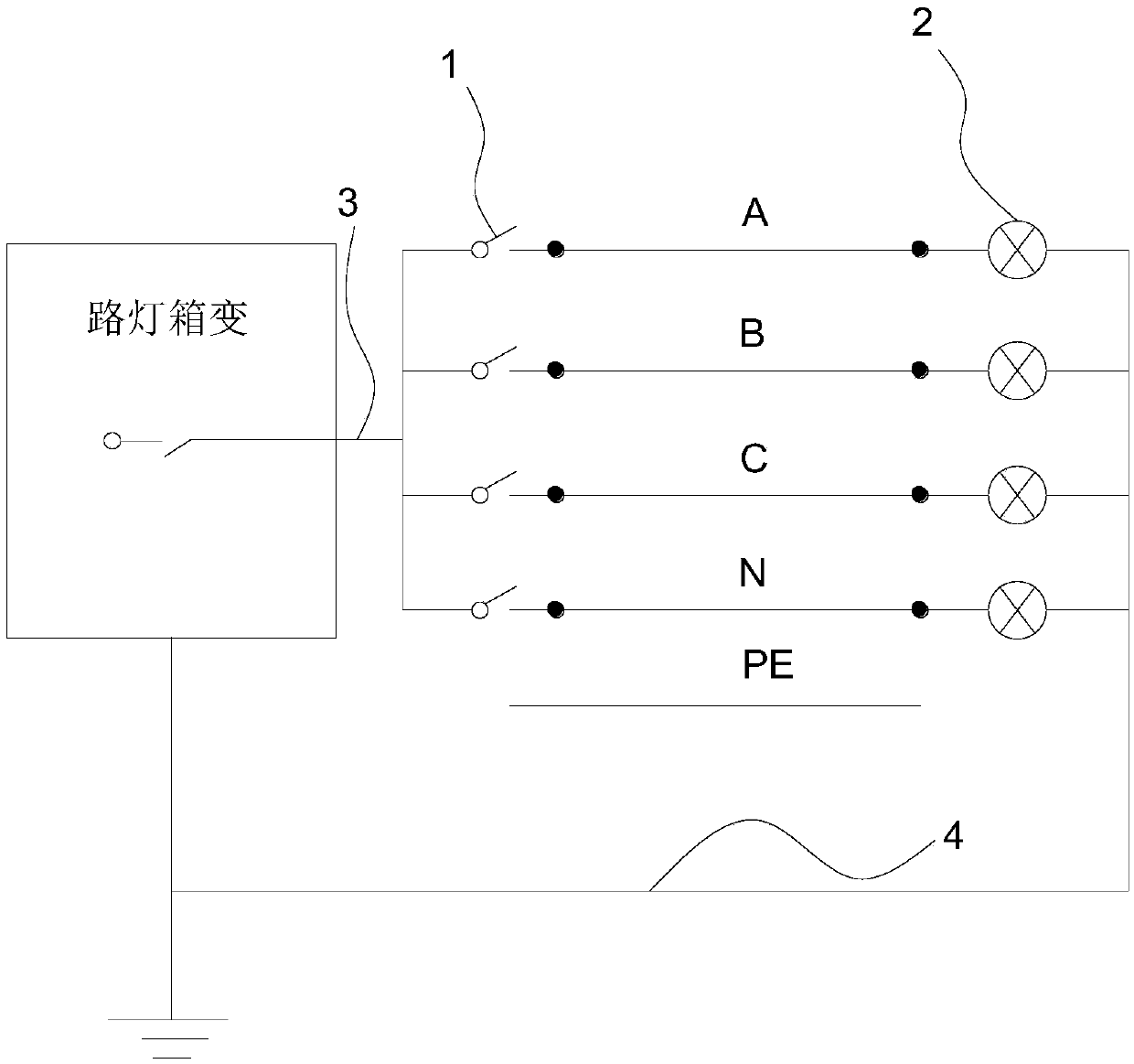

[0027] During the construction of municipal road street lamps, each street lamp needs 5 cables to connect to the bus in the hand hole well. These 5 cables are A cable, B cable, C cable, N cable and PE cable, A cable, B cable, C cable, The connections at both ends of the N cable and the PE cable must be corresponding. If one end of the A cable is connected to the A line interface of the street lamp, but the other end is not connected to the A line in the hand hole well, the street light cannot operate normally. Therefore, it is necessary to ensure that each cable The two ends are connected with the corresponding interface and the bus. Because the distance from the hand hole well to the street lamp is relatively long, the calibration line must be passed before wiring. The calibration method of the single-core cable of the road lighting system of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com