A light variable frequency flexible cable for ships and offshore engineering platforms and its manufacturing method

A flexible cable, marine technology, applied in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problem of easy deviation of the core position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

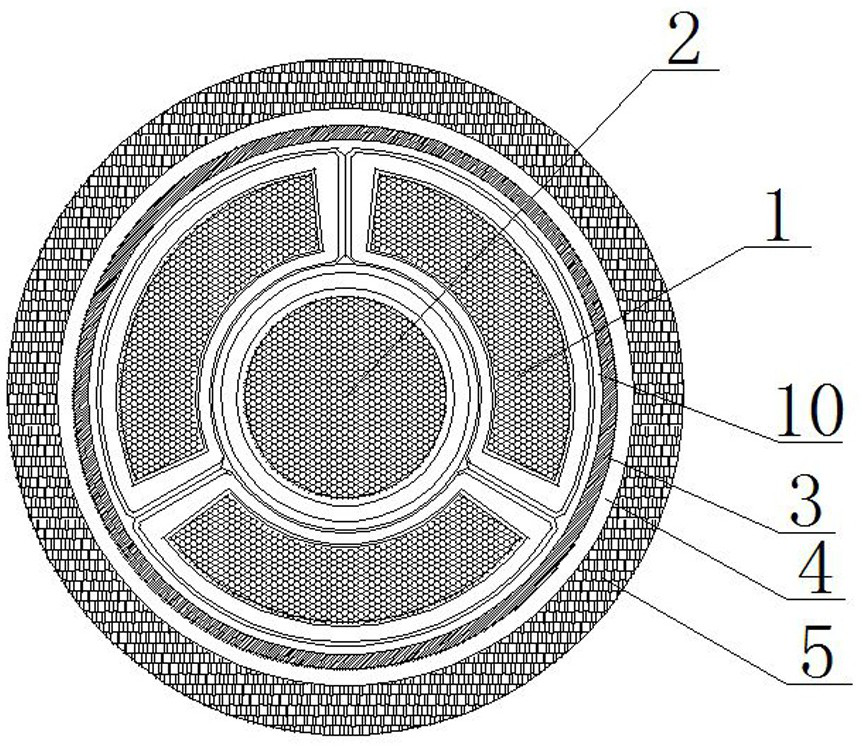

[0031] Such as figure 1 As shown, a light variable frequency flexible cable for ships and offshore engineering platforms of the present invention includes a main insulated core 1, a neutral core 2, a shielding layer 3, an armor layer 4 and an outer sheath 5, and the main insulated core 1 is three and its section is tile-shaped at 120 degrees. The three main insulated cores 1 form a complete ring and are set outside the neutral core 2. The shielding layer 3, the armor layer 4 and the outer sheath 5 are from the inside to the outside. The outside is sheathed on the outside of the main insulated wire core 1 in turn. The three main insulated wire cores 1 are in the shape of 120° tiles, and a neutral wire core 2 is distributed in the center of the three mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com