Automatic egg shelling method and device

A technology for eggs and egg shells, applied in the field of automation, can solve the problem of transferring broken shells into eggs, and achieve the effects of high production efficiency, reducing quality and labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Step 1. Place the egg vertically, identify the cavity area on the top of the egg, calculate the burnt track on the egg according to the cavity area, and obtain the height of the burnt track;

[0059] Step 2, burning out an etching track with a certain depth along the burning track on the egg;

[0060] Step 3, tilting the etched egg at a certain angle;

[0061] Step 4, absorbing the eggshell to be removed on the upper part of the etching track, and knocking the eggshell to be removed, so that the upper and lower parts of the egg are cracked along the etching track;

[0062] Step 5. Remove the eggshell on the top of the egg, reset it, and wait for the next shelling cycle;

[0063] Wherein, a negative pressure is provided during the knocking process to guide and collect debris generated on the etching track.

[0064] Specifically, including:

[0065] Step S10, identifying the cavity range of the egg to be shelled.

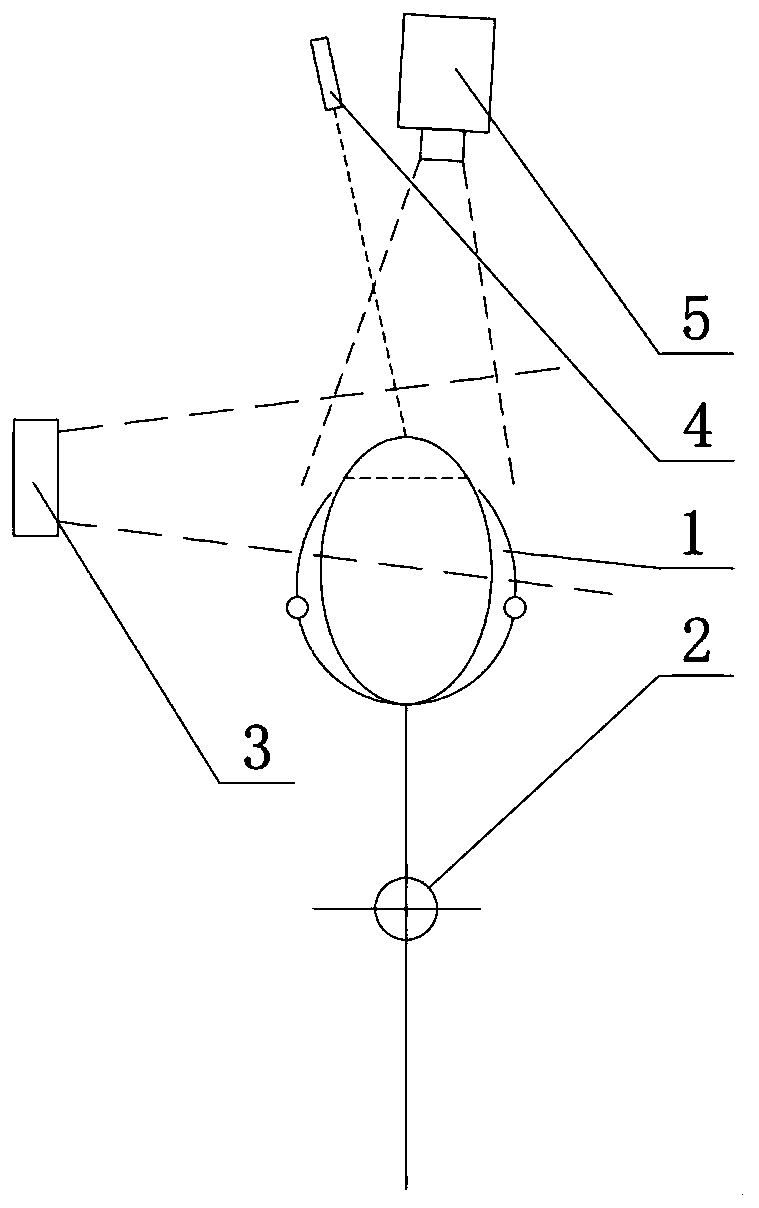

[0066] In this example, if Figure 1-9 As shown, the e...

Embodiment 2

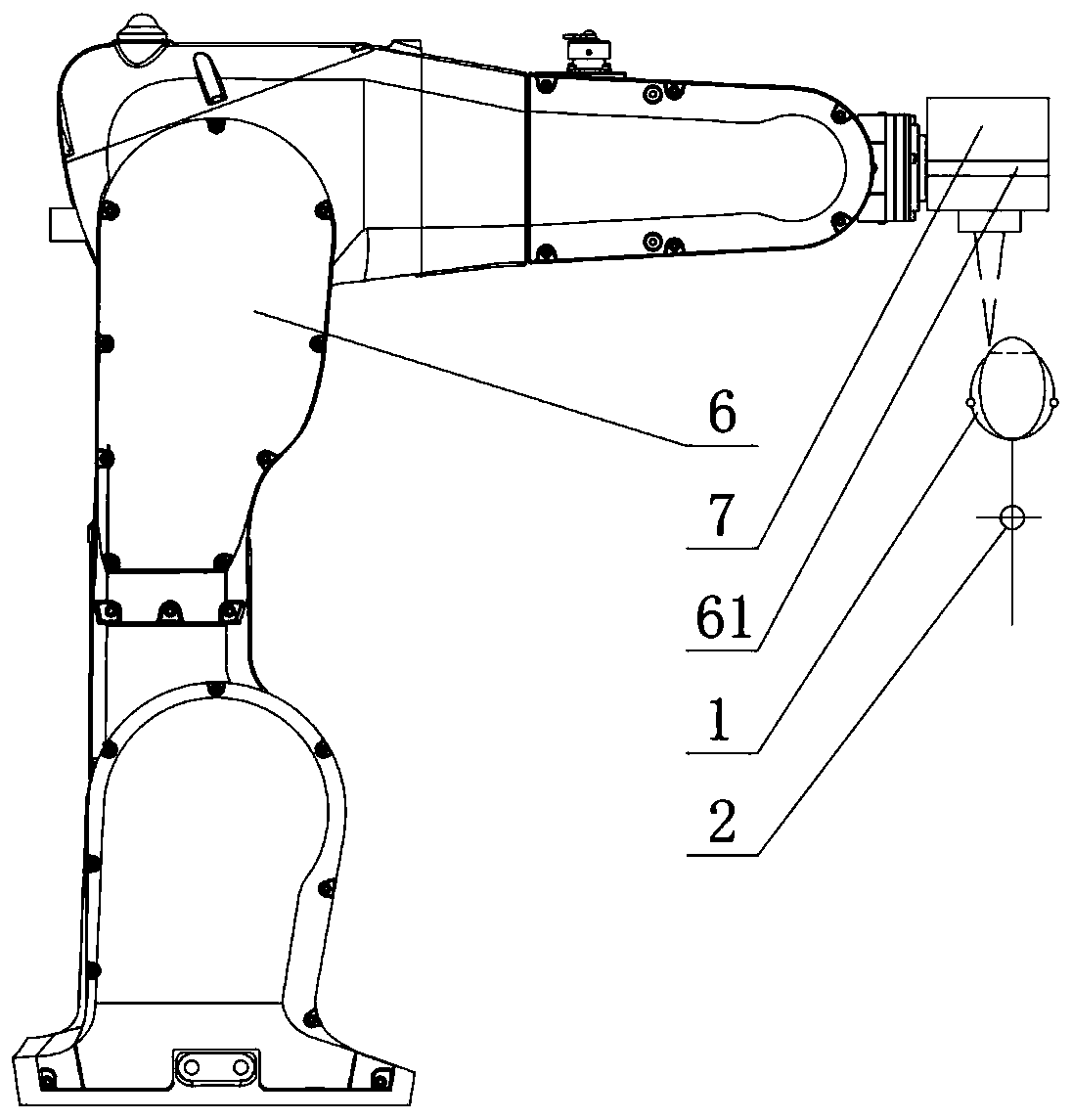

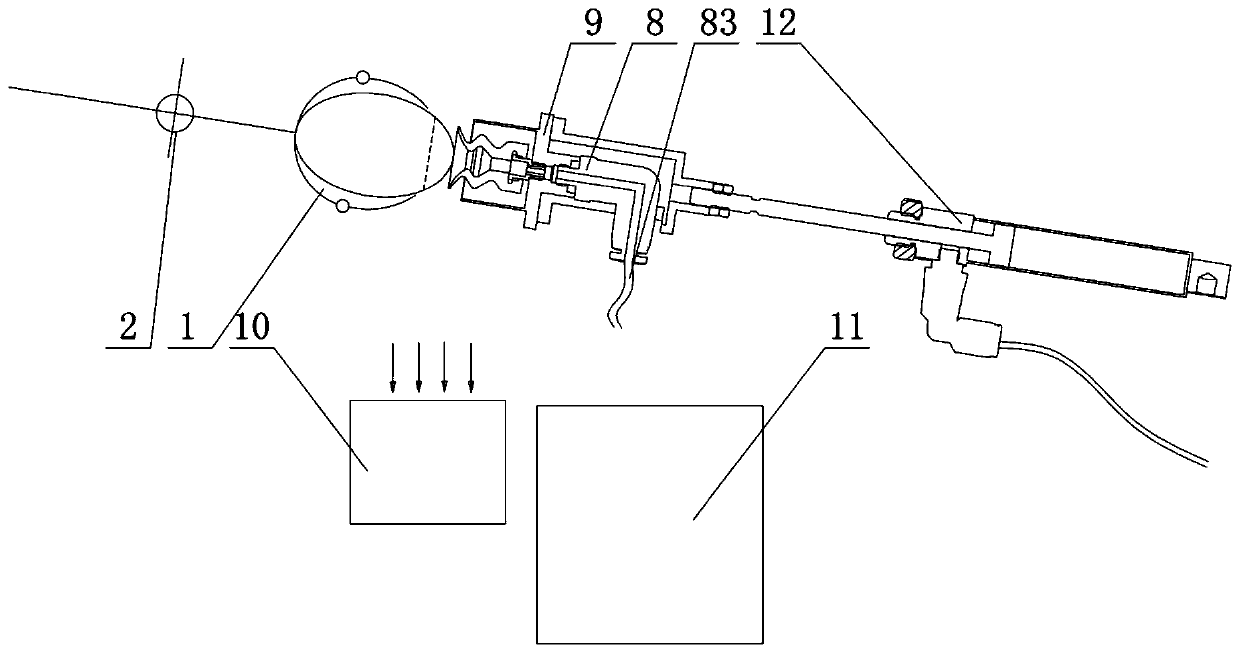

[0090] The present invention provides a kind of laser engraving and shelling process of automatic egg and egg with chicken embryo, now will describe the embodiment that is used for implementing a kind of automatic egg of the present invention and the egg laser engraving and shelling equipment that has chicken embryo , The equipment includes an egg tray 1 that can hold eggs, a visual inspection unit, a laser etching unit, a shell knocking and shelling unit, and a broken shell collection box 11, etc.

[0091] The egg tray 1 is a hollow structure with an open upper end. When an egg is placed in the egg tray 1, the upper part of the egg is exposed from the opening at the upper end of the egg tray 1. The exposed end includes the eggshell part that needs to be removed, that is, the exposed The end is the working part in the laser burning and shelling work. Further, the lower end of the egg tray 1 is connected and fixed with the egg tray rotating shaft 2. While supporting the egg tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com