Drag type cropping robot trolley for large cloth roll

A robot and tow-type technology, applied in the field of tow-type large cloth rolling and unwinding robot trolleys, can solve the problems of time-consuming and labor-intensive, hidden dangers, easy accidental injury, etc., and achieve the effects of convenient use, guaranteeing safety, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

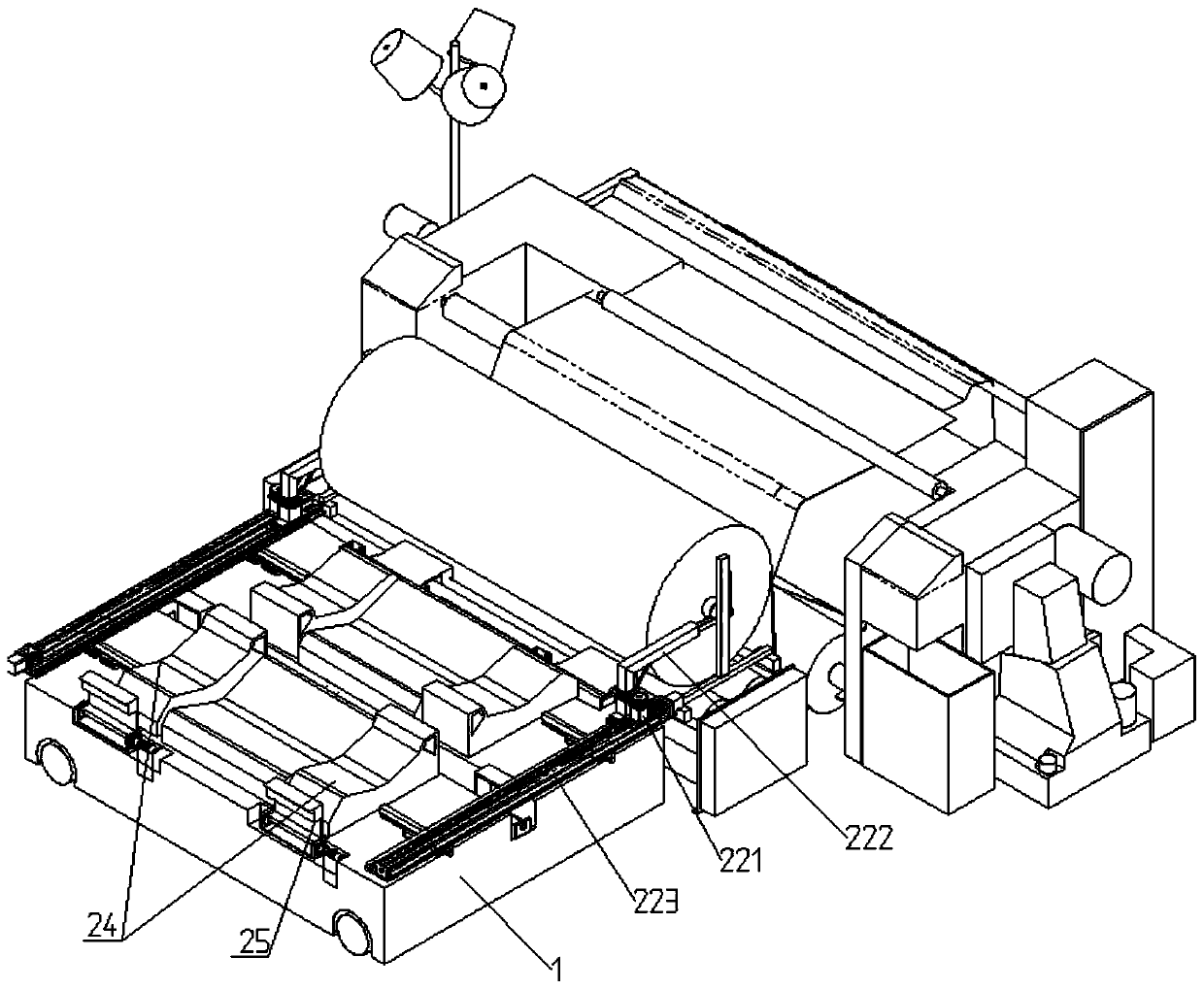

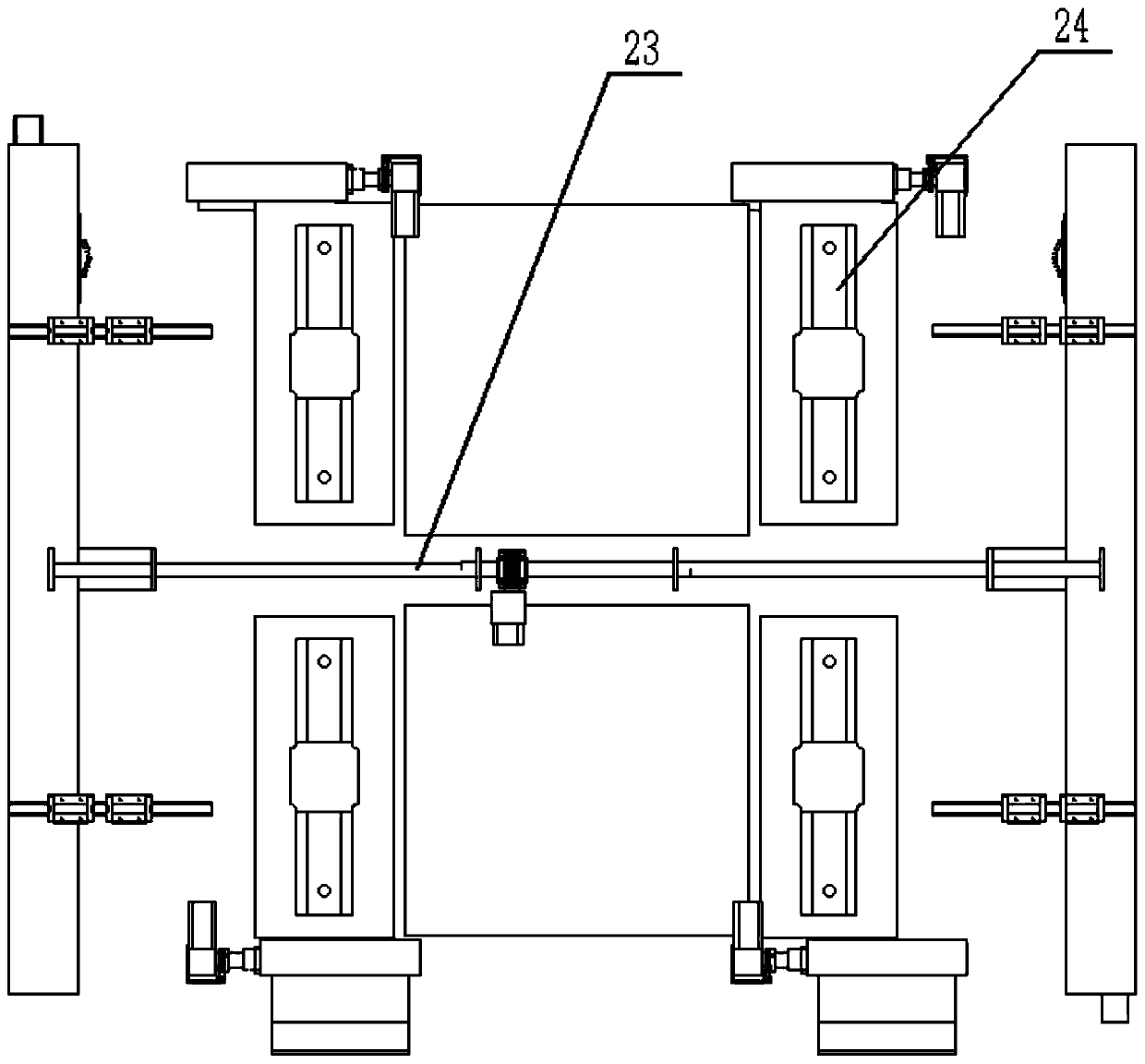

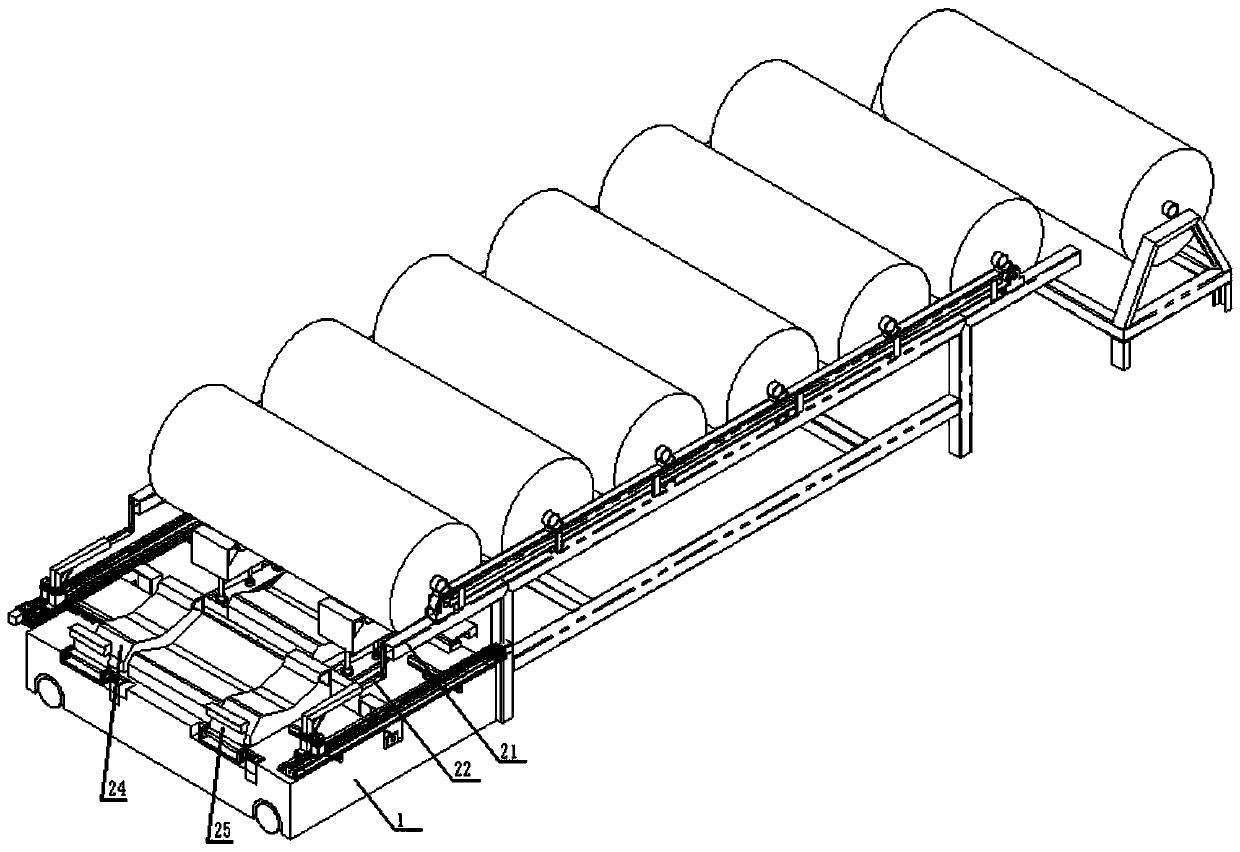

[0024] As an implementation, the drag mechanism 22 includes a horizontal rotation mechanism 221, an L-shaped bar 222, and a front and rear translation mechanism 223. The horizontal rotation mechanism 221 is arranged on the front and rear translation mechanism 223, and the front and rear translation mechanism 223 is used to drive The horizontal rotation mechanism 221 moves back and forth, the vertical end of the L-shaped rod 222 is fixed on the horizontal rotation mechanism 221, the horizontal end of the L-shaped rod 222 is provided with a hook 224, and the horizontal rotation mechanism 221 is used to drive the L-shaped The rod 222 rotates in the horizontal plane.

[0025] As an implementation, the horizontal rotation mechanism 221 includes a driving gear, a driven gear and a motor, the motor is used to drive the driving gear to rotate, the driving gear meshes with the driven gear, and the driven gear is fixed with L-shaped rod 222 .

[0026] As an implementation manner, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com