Self-luminous webbing knitting process

A self-illumination and craftsmanship technology, applied in the direction of weaving, fabrics, textiles and papermaking, etc., to achieve the effect of fabric firmness and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] A self-luminous ribbon weaving process, comprising the following steps:

[0047] 1), threading

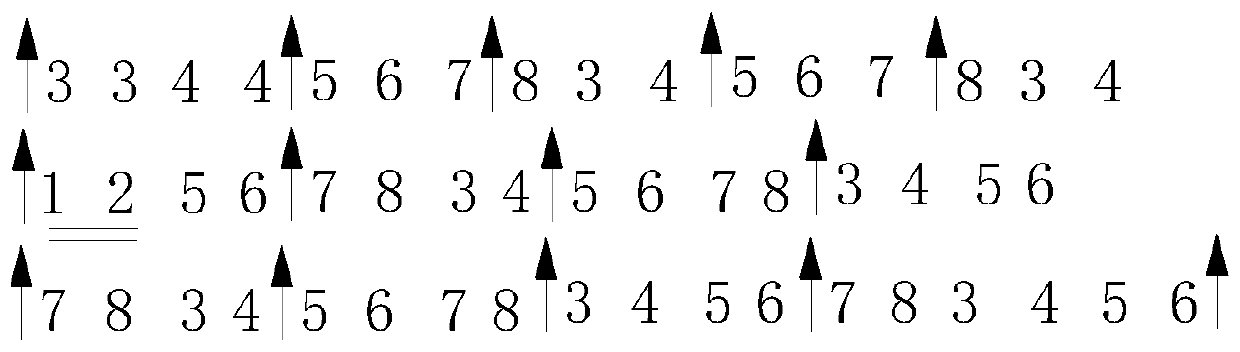

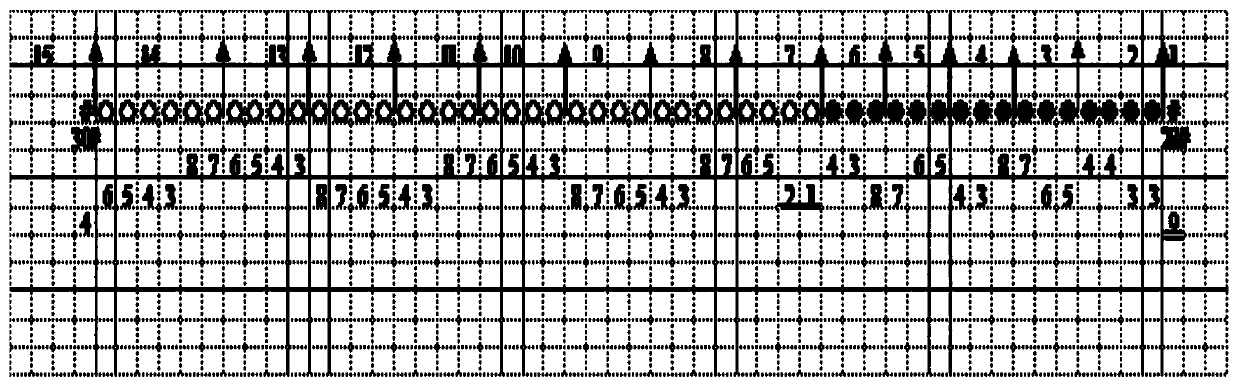

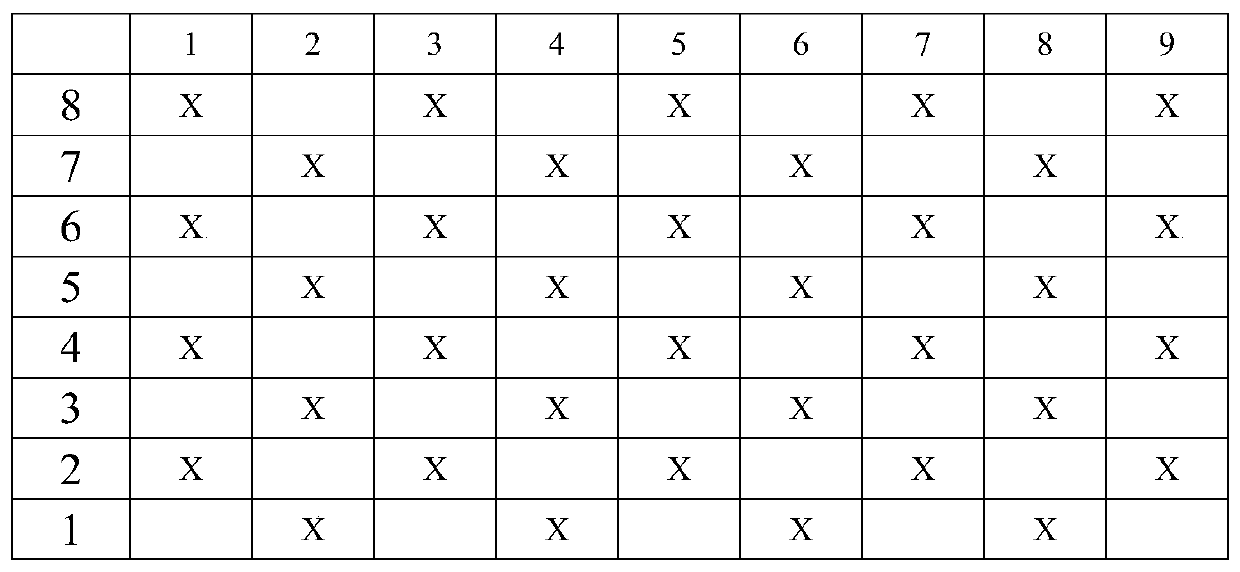

[0048] The drafting is 9 pieces of heald pages, such as figure 1 and figure 2 As shown, the number 1 represents the first yarn passing through the first heddle, the number 2 represents the second yarn passing through the second heddle, and so on; in figure 2 , between two "↑" indicates a reed, and the number on the upper side between two "↑" indicates the number of reed in the single independent unit, such as 6 indicates the sixth reed in the single independent unit; "○ "Indicates the type of rubber yarn corresponding to the elastic thread; "●" indicates the same type of warp yarn; "#" indicates the boundary line that coincides with the respective sides of the opening edge line and the final edge line, and the boundary line is determined in the loom. Marginal steel wire.

[0049] Specifically, the threading includes the following steps:

[0050] The threading is 9 hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com