An oblique embedding device for embedded parts used for climbing formwork suspension

A technology of embedded parts and climbing formwork, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., which can solve the problems of low construction efficiency, poor load-bearing capacity, and inability to tilt the embedded screw rod, etc. problem, to achieve the effect of fast and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

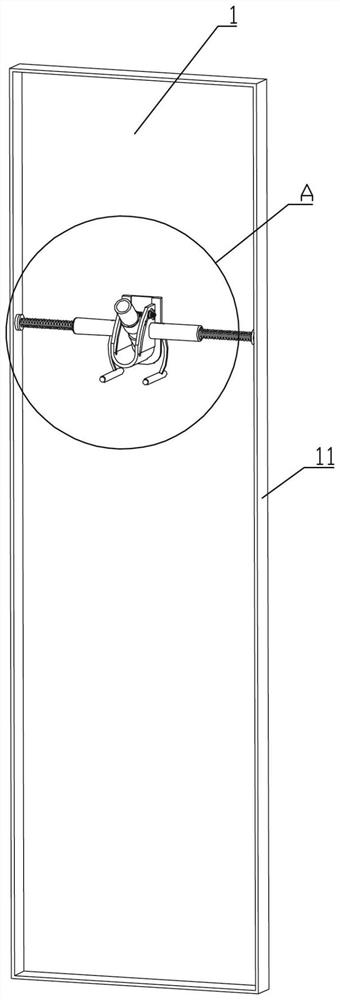

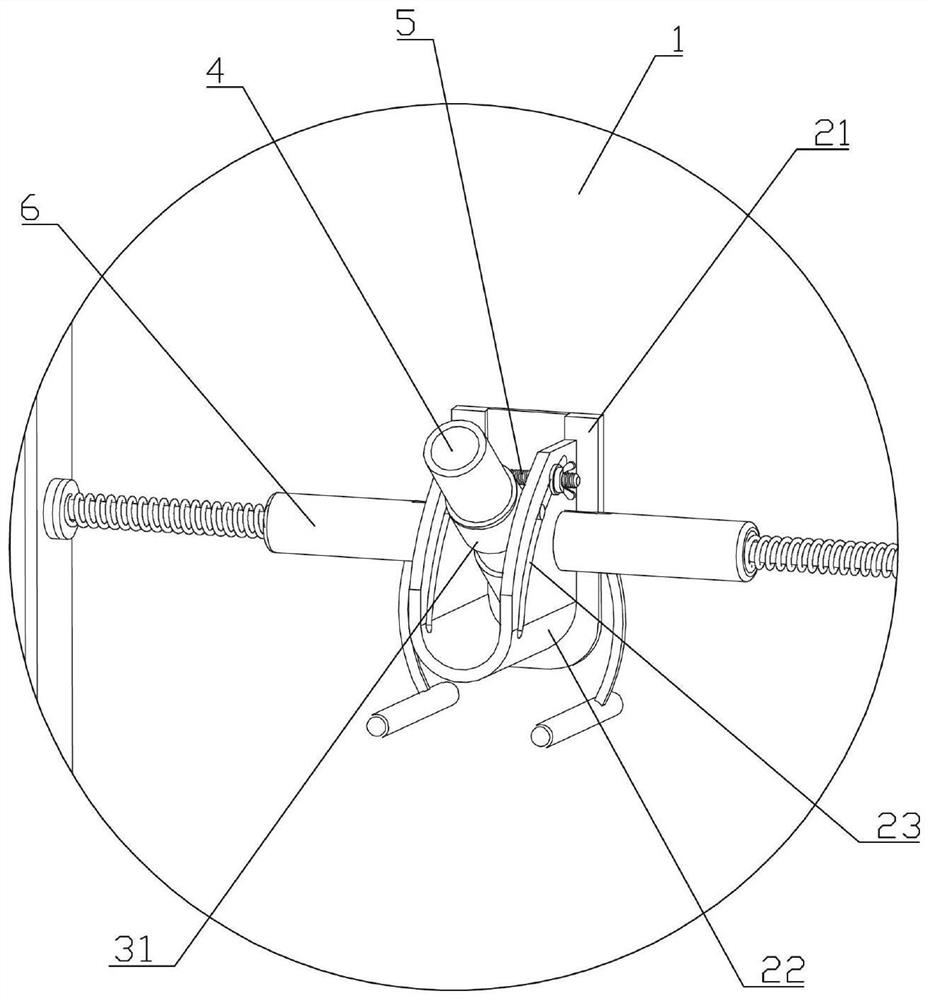

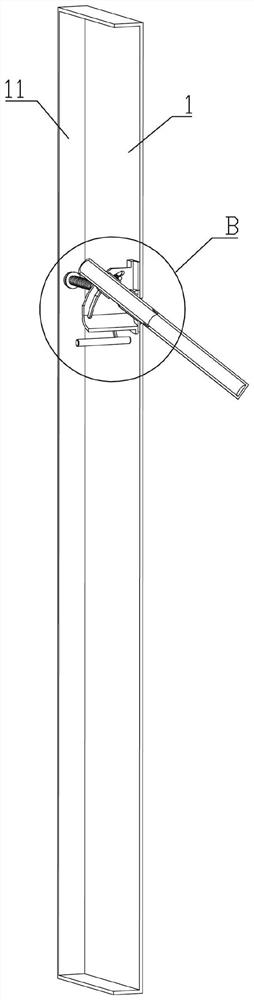

[0038] Such as Figure 1-11As shown, a kind of oblique embedding device for embedded parts used for climbing formwork suspension, including embedded parts 4 pierced on the aluminum formwork 1, the aluminum formwork 1 is provided with a back flute 11 and a reserved hole 12, and the embedded parts 4 is installed in the reserved hole 12 of the aluminum formwork 1, and the embedded part 4 is connected with a mounting seat, and the mounting seat includes an integrally formed base 21 and a mounting frame 22. The opposite sides of mounting seat are all fixedly installed with the same fixing mechanism of structure, and fixing mechanism comprises fixing sleeve 61, support bar 62, support spring 63 and driving lever 66, and fixing sleeve 61 is fixedly installed on the mounting frame 22, and support bar 62 is installed in the fixed sleeve 61, and the support spring 63 is sleeved on the support rod 62. The end of the support rod 62 is equipped with a fixed seat 64, and the support spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com