A double-index method for quantitatively judging the excavation time of gob-side roadway in extra-thick coal seam

A technology for extra-thick coal seams and roadways, which is applied in the field of roadway excavation and support in coal mines, can solve problems such as the sudden drop in benefits, the theoretical research and practical report on the excavation time of gob-side roadways for extra-thick coal seams, and the insufficient stability of the overlying rock movement. , to achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

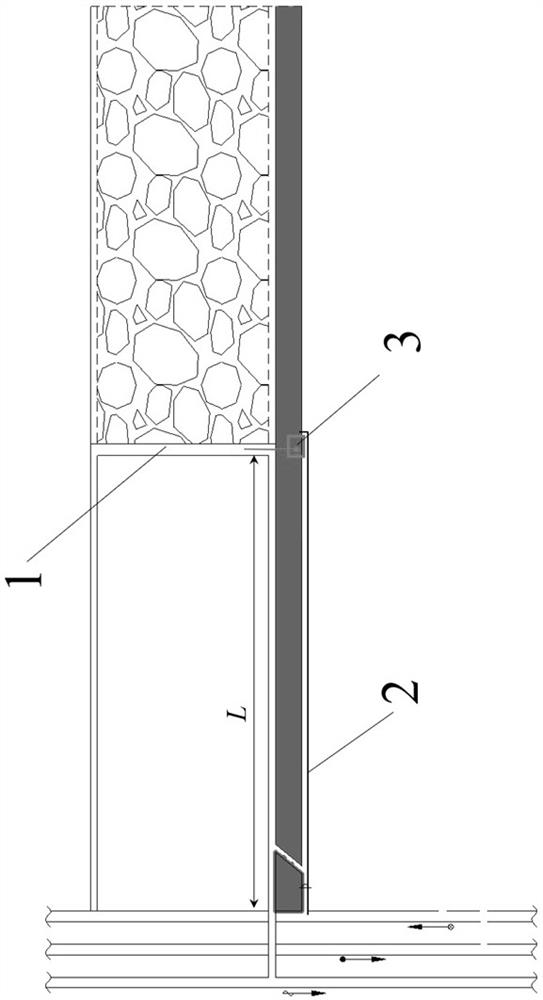

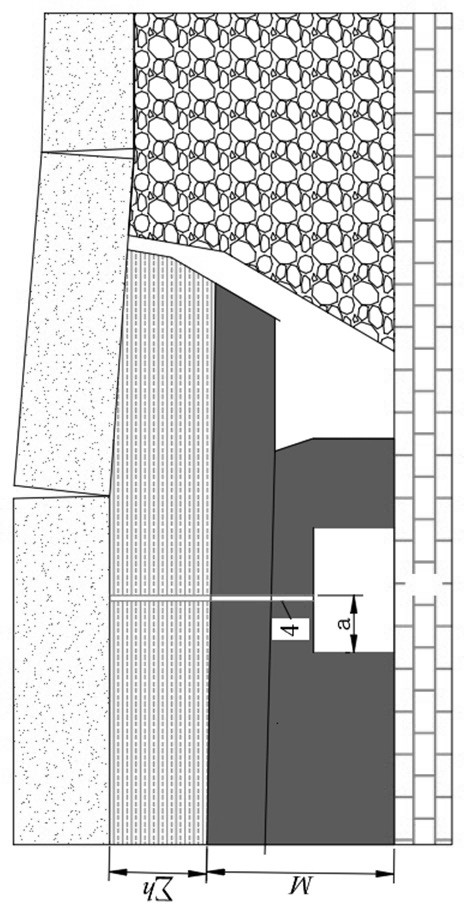

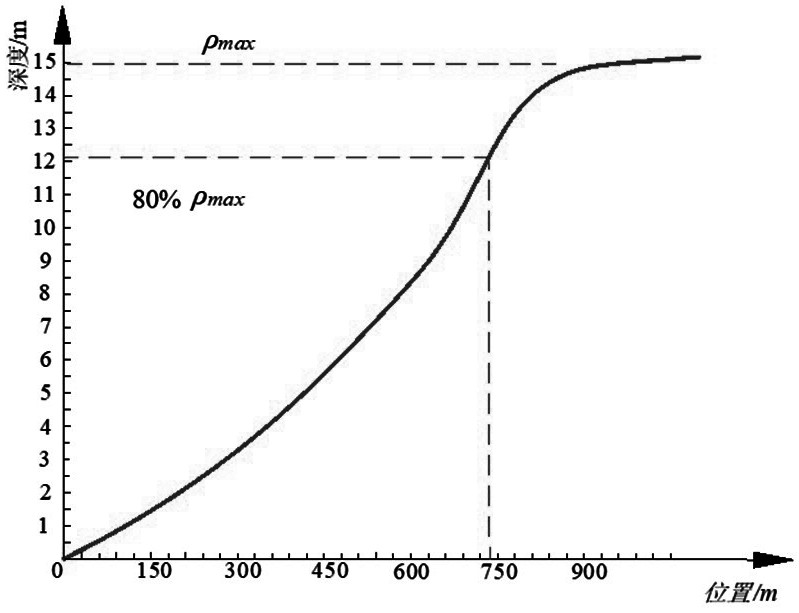

[0050] Such as Figure 1-3 As shown, the first step: taking the basic roof subsidence as an index, the excavation time T along the gob 1

[0051] (1) On-site investigation and indoor experiment

[0052] The 201 working face of a mine in Shanxi mainly mines 2# coal seam, with an average thickness of 15m. The immediate roof is sandy mudstone with an average thickness of 6.0m, and the basic roof is siltstone with an average thickness of 9.2m. The mine adopts fully mechanized caving mining technology for coal mining, the coal mining height is 3m, the coal setting height is 12m, and the coal recovery rate is 75%.

[0053] Laboratory experiments show that the disintegration coefficient of the broken coal body is 1.3, the disintegration coefficient of the caving rock mass is 1.2, the basic roof elastic modulus is 4.39GPa, and the basic roof viscous modulus is 85.34GPa. The strength is 63MPa, and the compressive strength of broken top coal is 17MPa.

[0054] (2) Substitute into fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com