Pipe butt joint connection device for construction site

A technology for construction sites and connection devices, which is applied in the directions of non-removable pipe connections, pipe laying and maintenance, pipes/pipe joints/fittings, etc. Easy to take, beautiful to install, and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

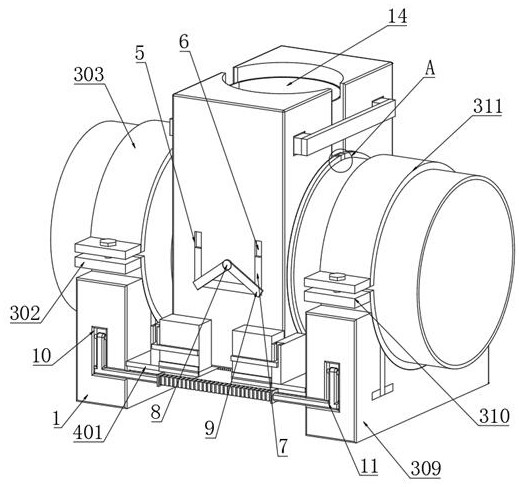

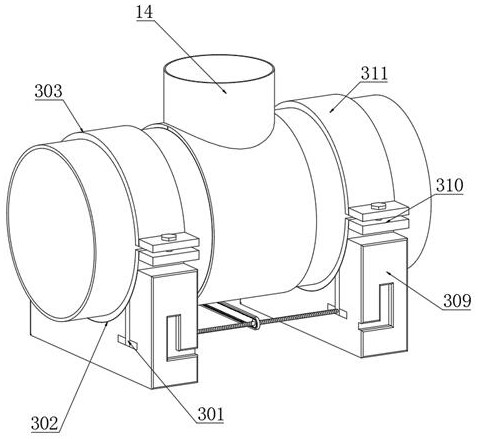

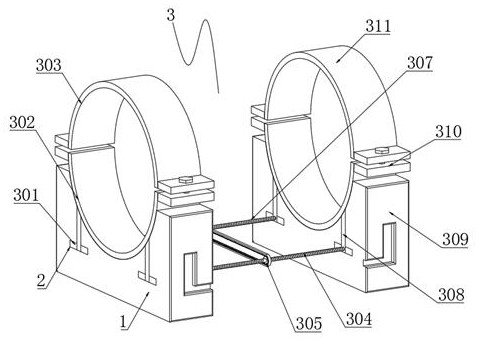

[0040] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a pipe butt joint connection device for construction sites, including a first fixed frame 1, and both sides of one end of the first fixed frame 1 are provided with chute 2, and two chute 2 The middle part of the inner wall is provided with a leveling mechanism 3, and the leveling mechanism 3 includes a main moving T-bar 301, a main moving ring 302, a main fixing ring 303, a main double-ended screw rod 304, a sawtooth runner 305, an inner sawtooth belt 306, From the double-ended screw mandrel 307, from the mobile T-shaped bar 308, the second fixed frame 309, from the mobile ring 310 and from the fixed ring 311;

[0041]The middle parts of the inner walls of the two chutes 2 are provided with main moving T-bars 301, and the top edges of the two main moving T-bars 301 are welded with main moving rings 302, and the top edges of the main moving rings 302 are fixedly equipped with mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com