Dynamic condensation net and extractor hood

A range hood and dynamic technology, applied in the field of range hoods, can solve the problems of many stains, difficult to clean, and low separation degree of the hood, and achieve the effects of increasing the probability of collision, improving the degree of grease separation, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

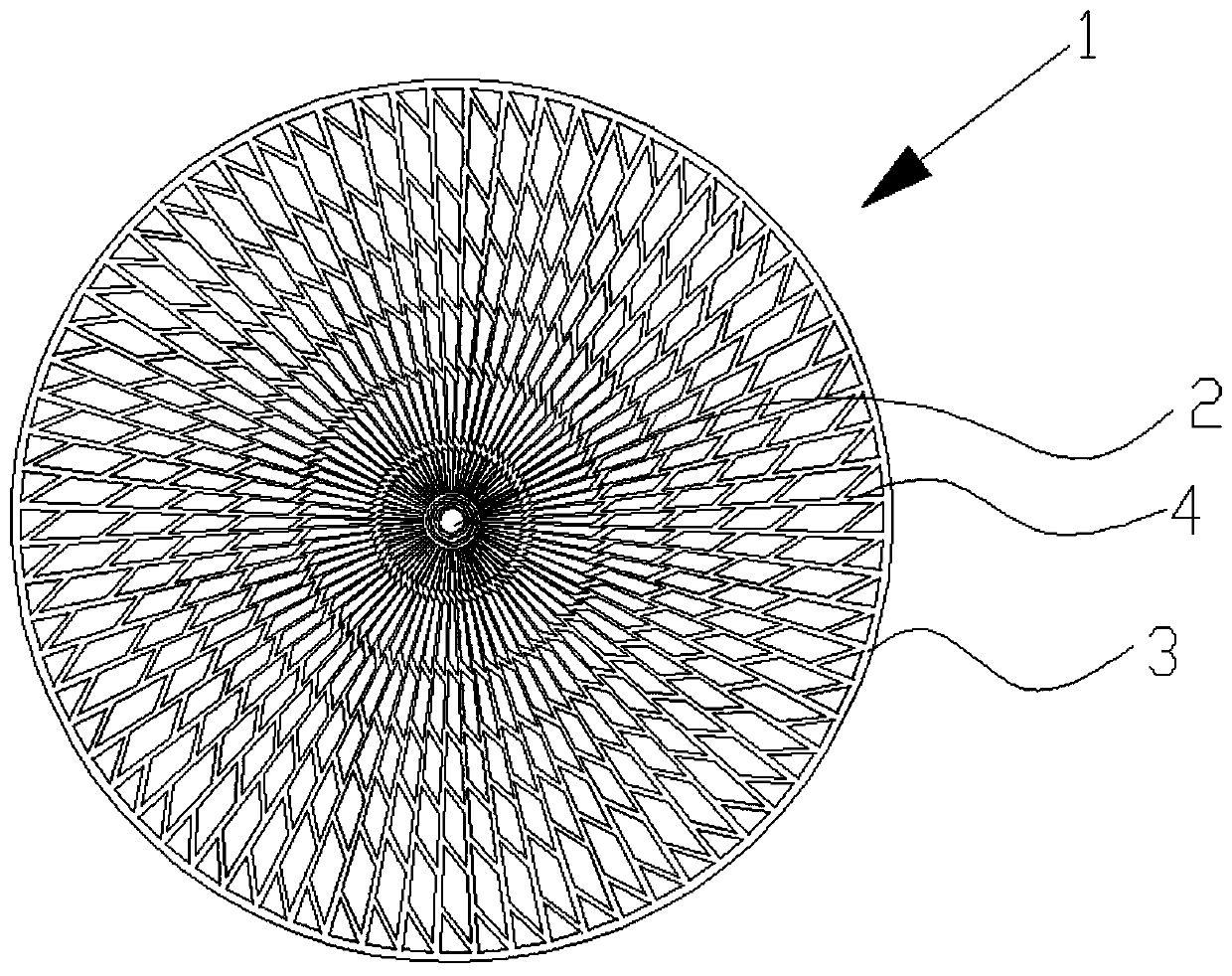

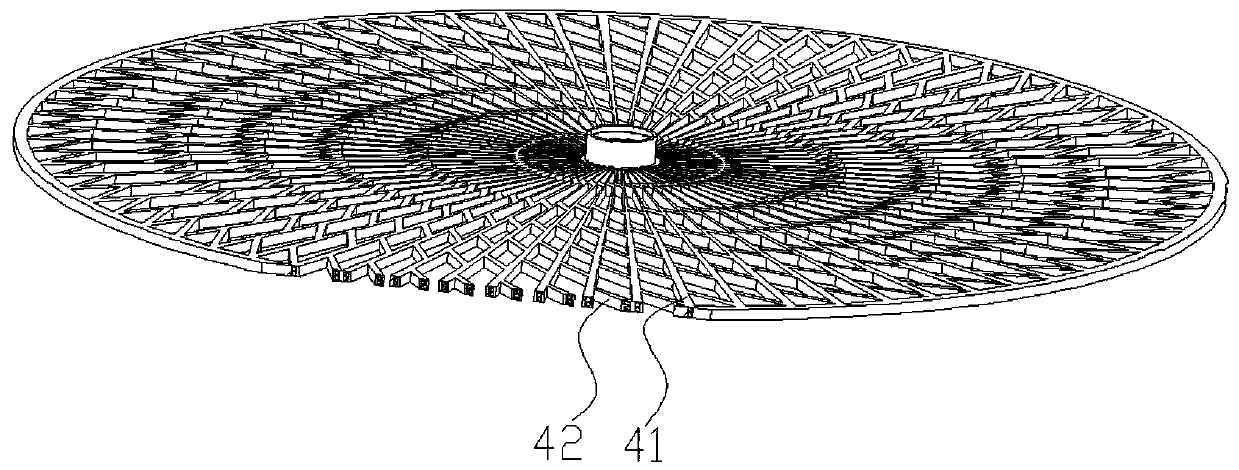

[0026] See attached Figure 1-3 It shows a dynamic condensation net 1 of the present invention, which includes a condensation net body, and the condensation net body includes an installation part 2, an outer frame 3 and spokes 4, wherein the outer frame 3 is arranged outside the installation part 2, and the The spokes are connected between the installation part 2 and the outer frame 3 and are distributed at intervals in the circumferential direction. A waterway system is arranged in the outer frame 3 and the spokes. The water inlet and outlet connected to the above waterway system.

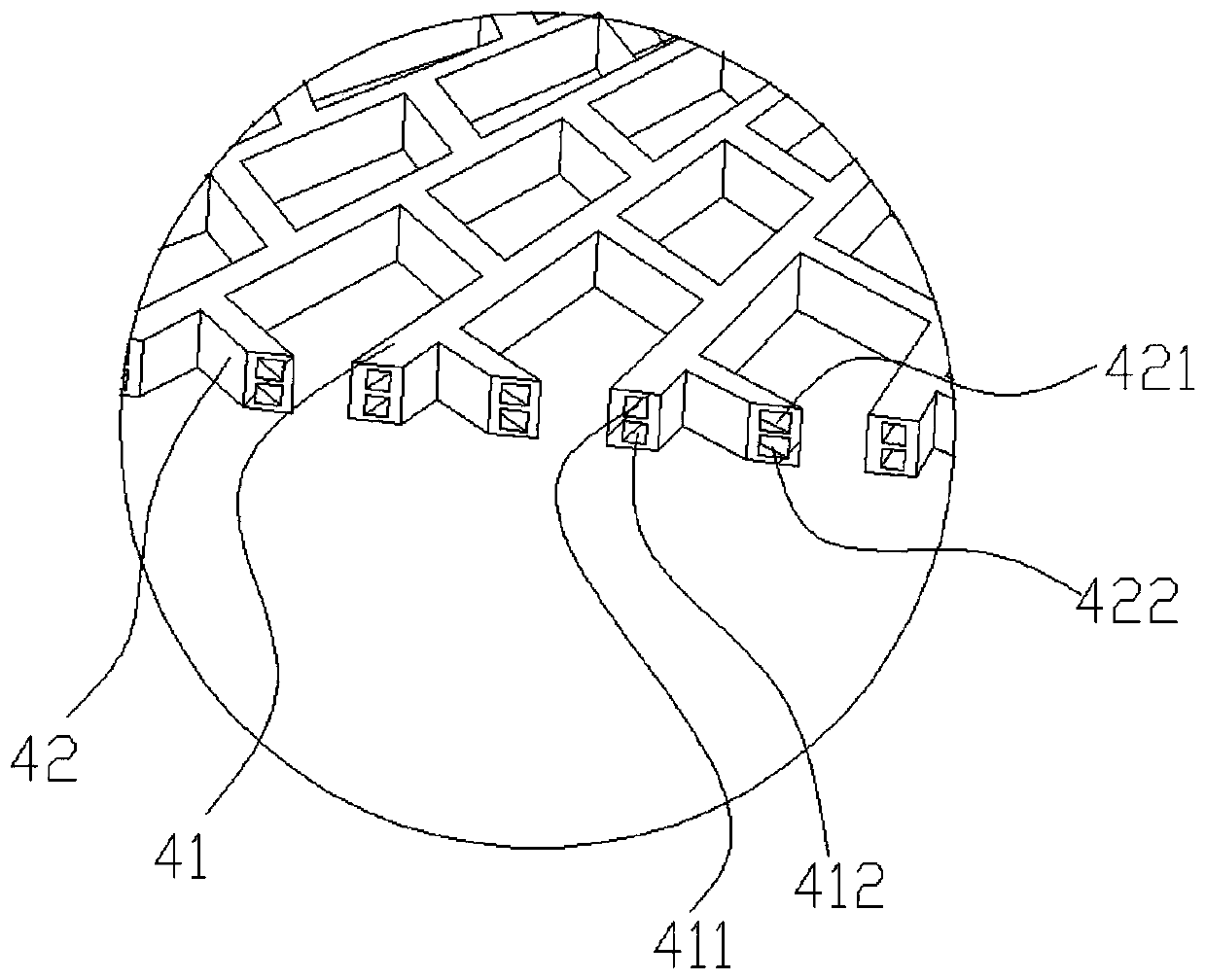

[0027] Preferably, the spokes 4 include main spokes 41 and sub-spokes 42, the main spokes 41 are connected between the mounting part 2 and the outer frame 3, and between two adjacent main spokes 41 The sub-spokes 42 are provided, and the main spokes 41 and the sub-spokes 42 are arranged between the installation part 2 and the outer frame 3. The arrangement is tight, and the method of physical int...

Embodiment 2

[0030] See attached Figure 4-7 It shows a range hood of the present invention, including a hood casing 100 and a fan system 110, wherein the fan system 110 is arranged in the hood casing 100, and the fan system 110 includes a motor and an impeller, and the motor Connected with the impeller, the range hood includes the aforementioned dynamic condensation network 1, the dynamic condensation network 1 is arranged on the fan system 110 and installed on the rotating shaft of the motor. An installation hole is formed in the installation part 2, and the installation hole is screwed to the rotating shaft of the motor, and the condensation net body is arranged in front of the impeller and rotates synchronously with the impeller. Through high-speed rotation, the collision probability between the dynamic condensation net 1 and the oil in the oil fume is increased, which is equivalent to increasing the contact area between the oil fume and the dynamic condensation net 1, and the dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com