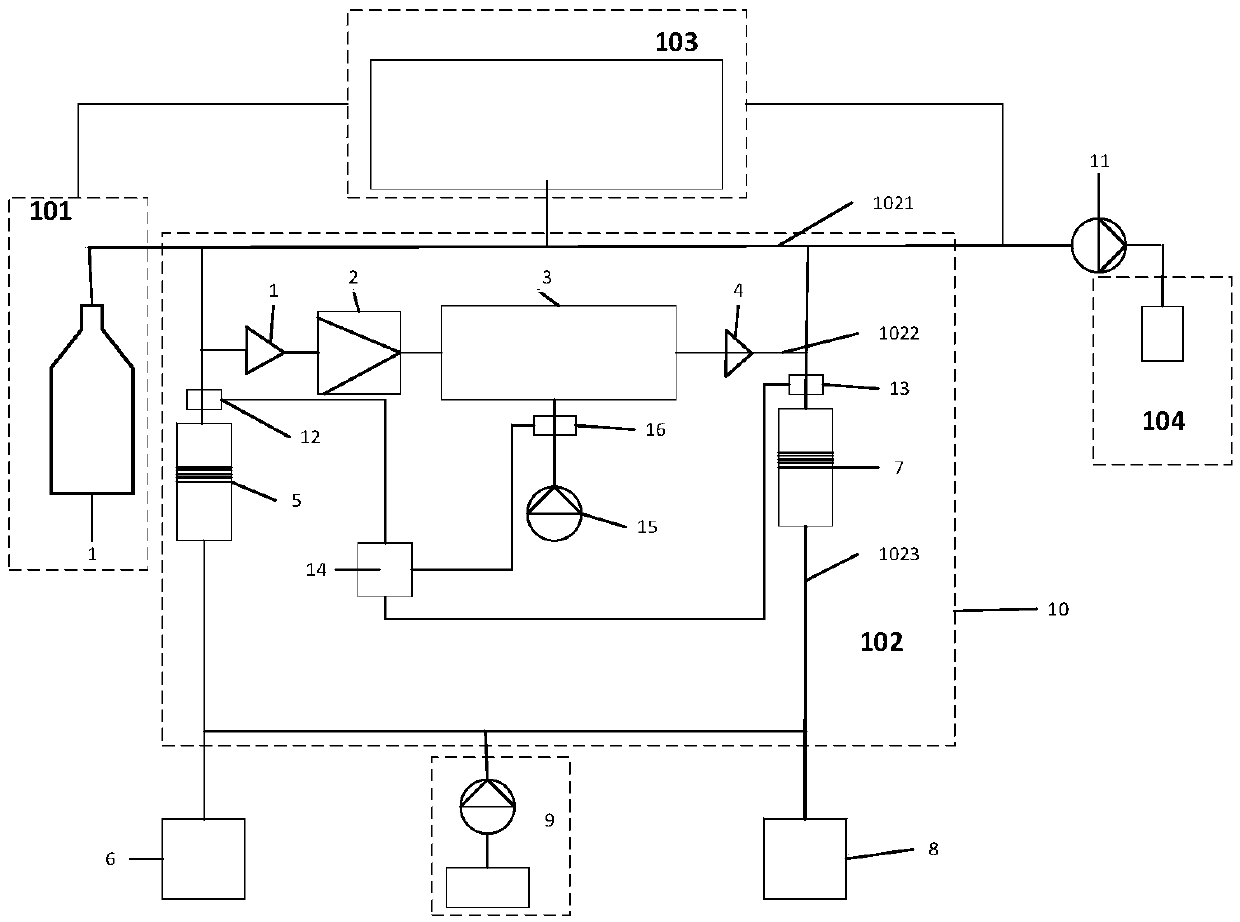

Core sulfur analysis system

An analysis system and core technology, applied in analysis of materials, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems such as the inability to accurately evaluate the amount of sulfur deposition in real time and the permeability damage of reservoir rock samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

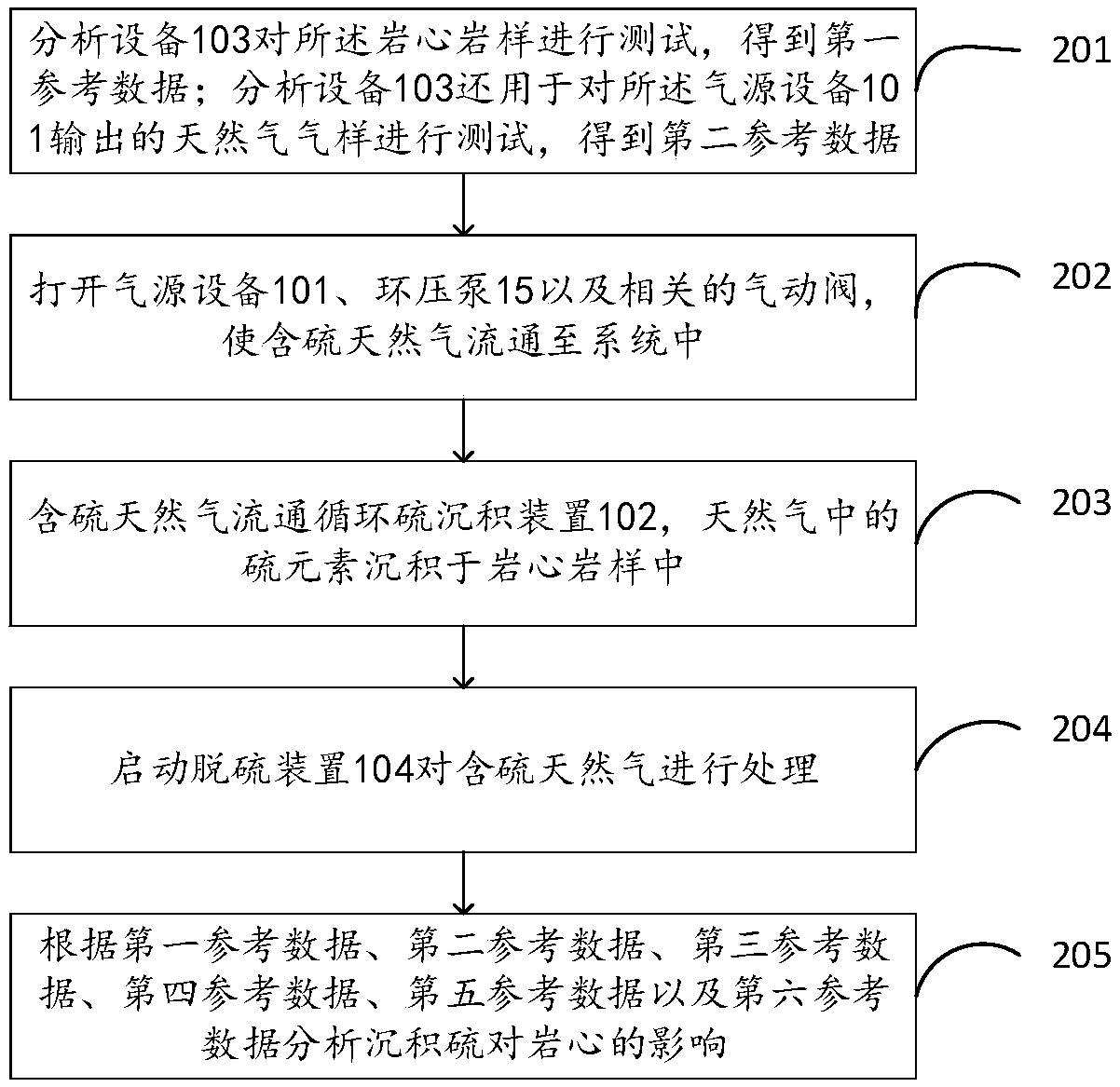

Method used

Image

Examples

Embodiment approach

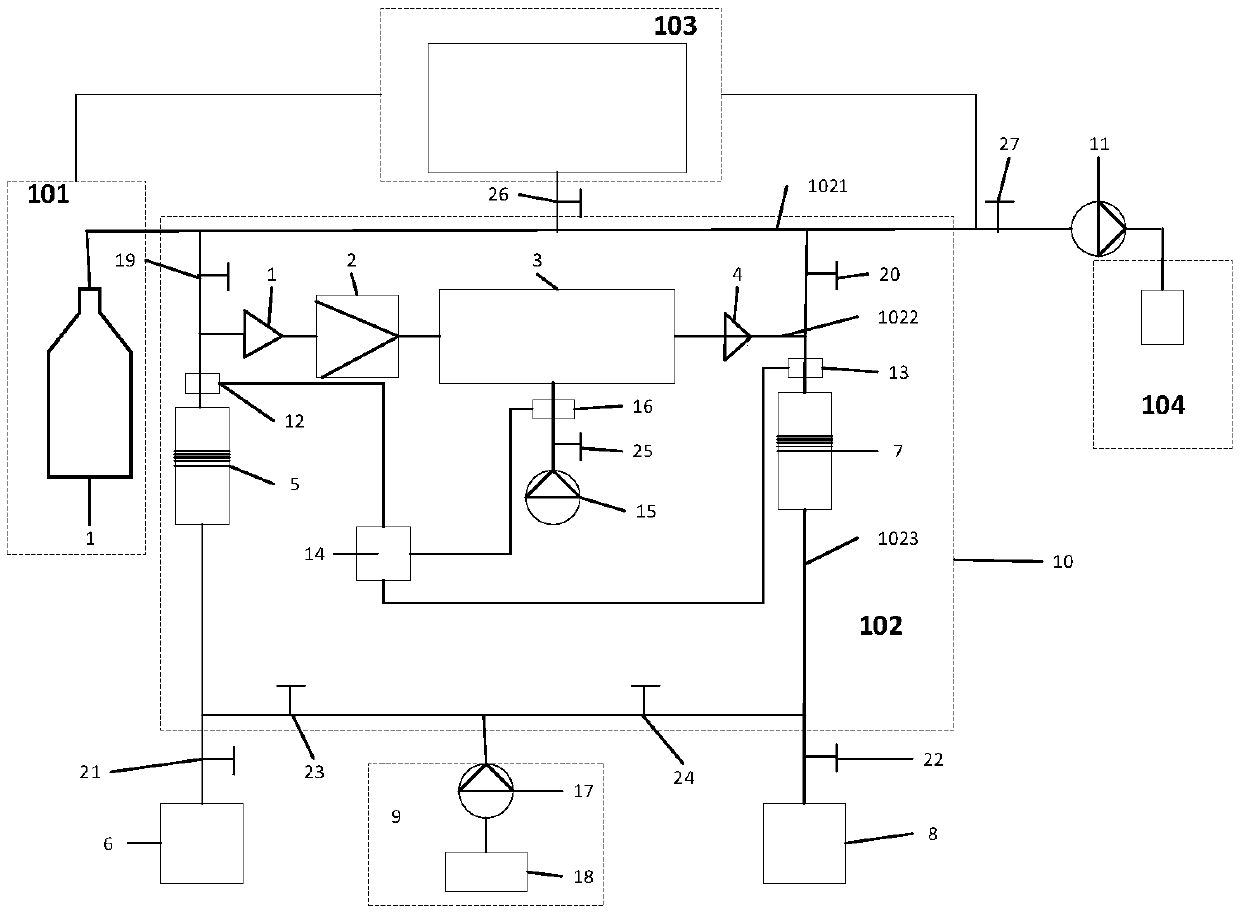

[0046] 1. The smart terminal 14 can be connected with the first pressure sensor 12 and the second pressure sensor 13, so as to obtain the pressure information of the upper ends of the first piston 5 and the second piston 7 in real time.

[0047] Two, the smart terminal 14 can be connected with the third pressure sensor 16, thereby obtaining the pressure information in the ring pressure pump 15 in real time;

[0048] 3. The smart terminal 14 can be connected with the first pressure sensor 12, the second pressure sensor 13 and the third pressure sensor 16, thereby obtaining the pressure information in the first piston 5, the second piston 7 and the ring pressure pump 15, and then comprehensively The pressure information of the three places can grasp the process of sulfur deposition and the state of the system as a whole.

[0049] In one embodiment, the ring pressure pump 15 can be a constant speed and constant pressure pump, and the ring pressure pump 15 is provided with an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com