A Rapid Method for Estimating the Lifetime of Atomic Gas Cells

A technology of atomic gas chamber and gas chamber, which is applied in the field of rapid evaluation of atomic gas chamber life, can solve the problems of high cost, slow decay of alkali metal time, and low efficiency, so as to eliminate influence, shorten consumption cycle, and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with example this aspect is described in further detail:

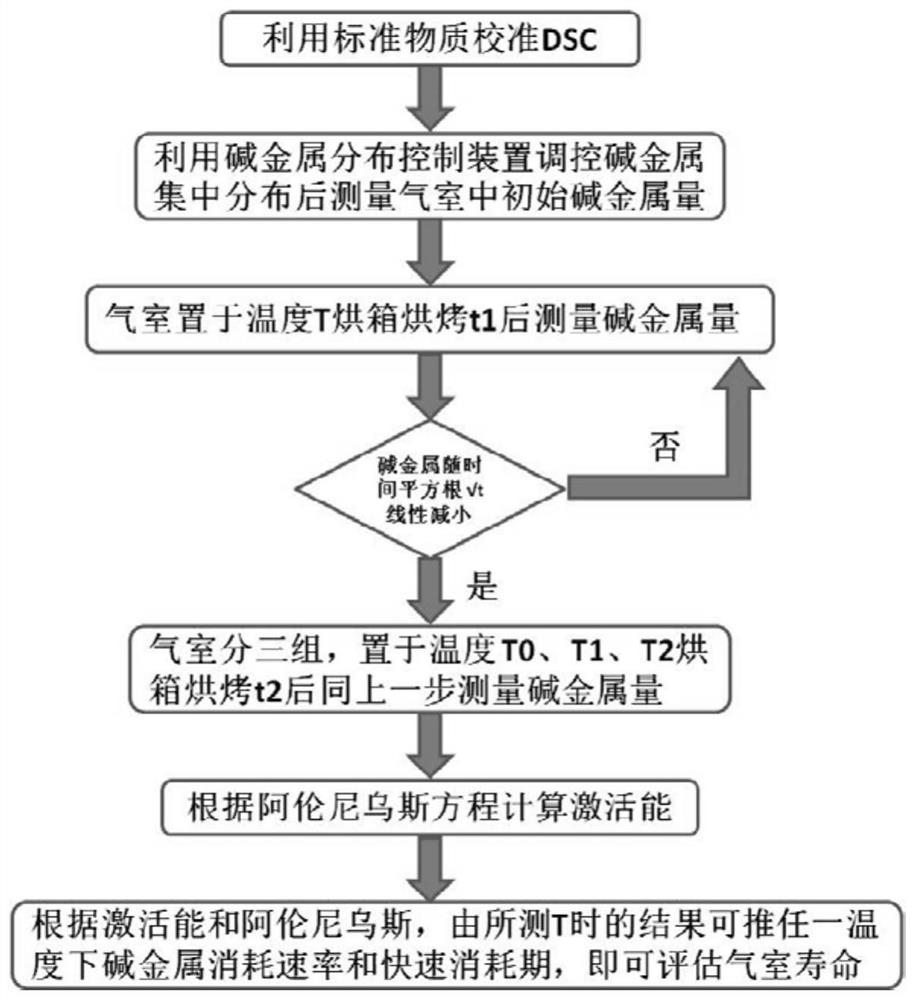

[0026] like figure 1 As shown, the present invention rapidly evaluates the method for atomic gas cell lifetime, specifically comprises the following steps:

[0027] (1) The differential scanning calorimeter (DSC) was calibrated with standard materials.

[0028] Use a high-precision balance to weigh 10 mg of five different thermal analysis standard substances (such as Ga, In, Sn, Pb, Zn), and prepare 6 empty shells that are the same as the glass shell of the atomic gas cell, such as the diameter of the atomic gas cell for a magnetometer. 10mm, length 15mm, five of which are packaged with 10mg of standard substances with five different melting points, one is a reference gas chamber (unfilled), and the melting point and heat of fusion of these five standard substances are measured by differential scanning calorimeter (DSC) Perform temperature calibration and enthalpy calibration.

[0029] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com