A production process for ant-proof optical cable

A production process and anti-ant technology, which is applied in the field of optical cable production, can solve the problems of poor anti-ant effect, unfriendly environment, and unsustainable chemical anti-ant, etc., to achieve improved anti-ant effect, excellent anti-ant effect, and continuous anti-ant effect long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

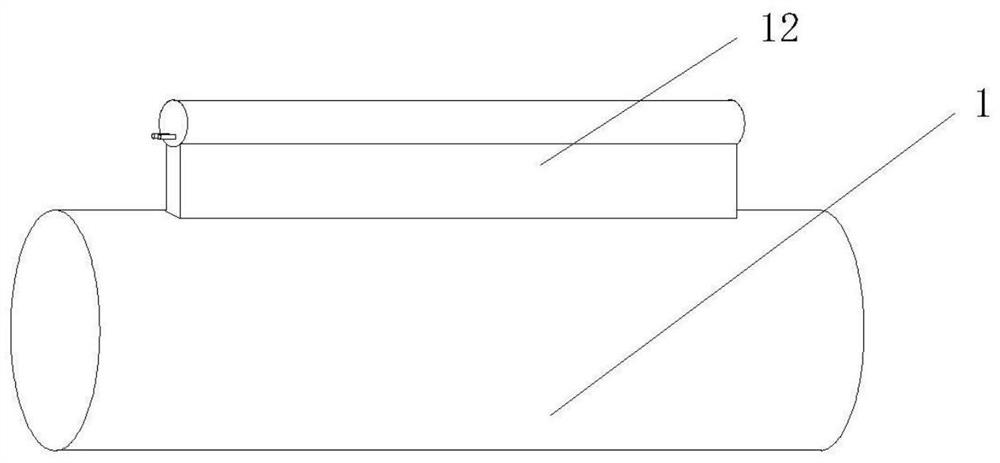

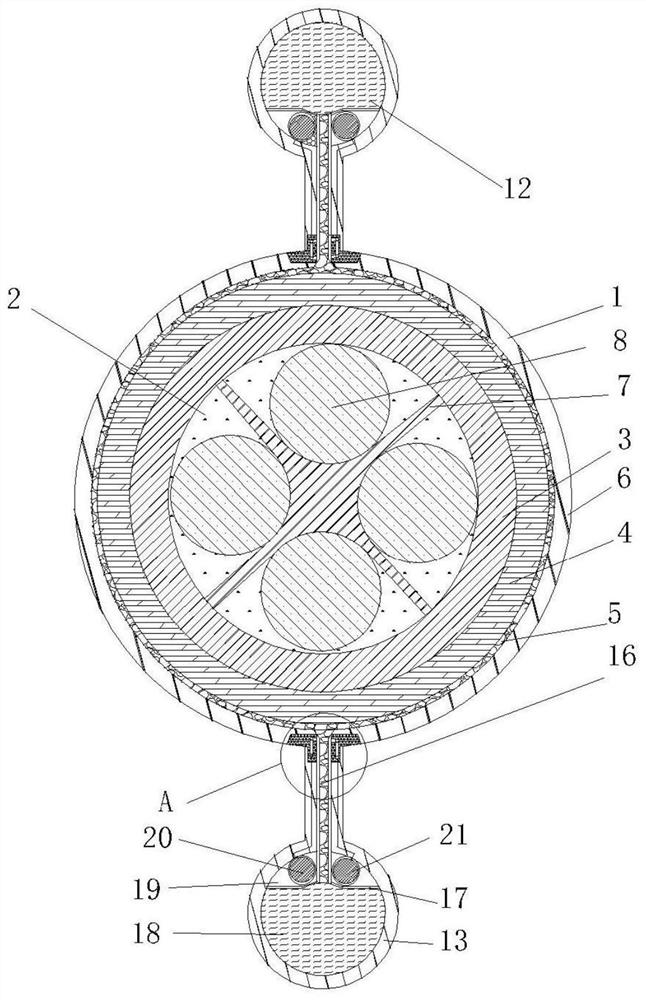

Embodiment 1

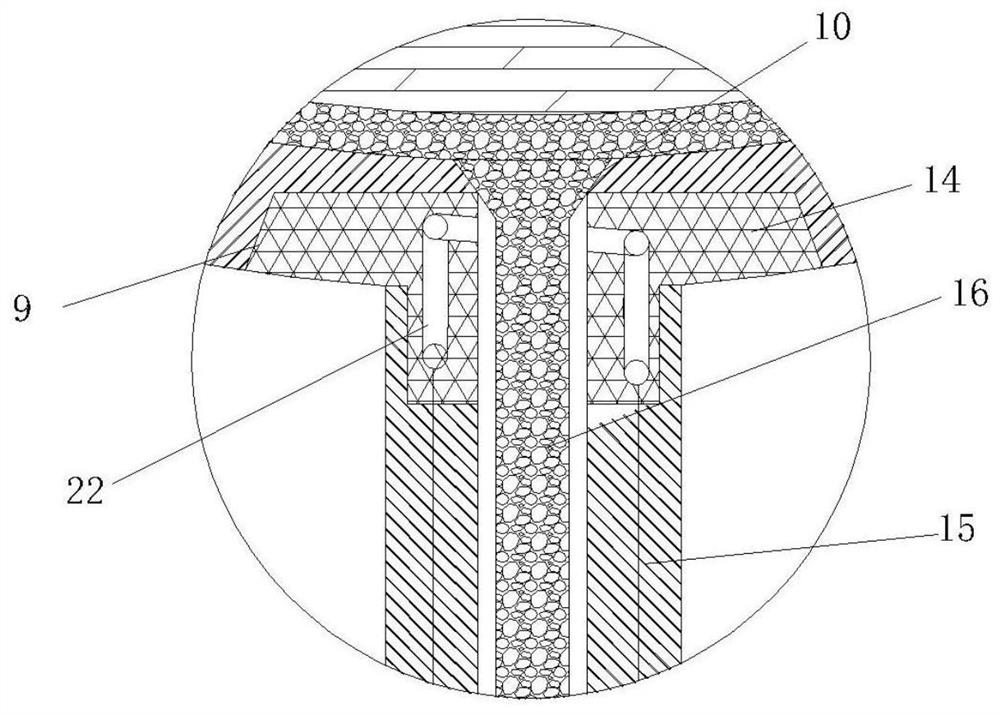

[0047] like figure 1 , figure 2 , image 3 and Figure 4 As shown, an ant-proof optical cable, comprising: an optical cable main part 1, the optical cable main part is provided with a core part 2, a flame-retardant layer 3, a waterproof layer 4, a capillary layer 5 and a PVC layer 6 sequentially from the inside to the outside, The core member includes a skeleton 7 and an optical fiber 8 attached to the skeleton. Fiber paste is filled between the skeleton and the optical fiber. The capillary layer is made of a material with capillary pores, and the capillary layer is adsorbed with an ant-proof solution. The ant solution adopts a pyrethrin solution with a mass percentage of 1%-3%.

[0048] The outer surface of the PVC layer is a smooth curved surface, and the PVC layer is provided with several strip-shaped installation grooves 9, the bottom wall of the installation groove has a perforation 10 connecting the capillary layer, and several sealing strips 11 are housed in the ins...

Embodiment 2

[0063] like Image 6 As shown, an ant-proof optical cable includes a main part of the optical cable, and the main part of the optical cable is sequentially provided with a core part, a flame-retardant layer, a waterproof layer, a capillary layer, a smooth PVC layer on the outer surface and a capillary tube from the inside to the outside; the core part includes The skeleton and the optical fiber attached to the skeleton are made of a material with capillary pores, and the anti-ant solution is adsorbed in the capillary layer.

[0064] The PVC layer is connected with an anti-ant component integrally formed with the PVC layer. The anti-ant component includes a storage capsule storing an anti-ant solution and a connection block. One end of the connection block of the anti-ant component is connected to the storage capsule, and the other end is connected to the PVC layer. The capillary runs through the connection Block and PVC layer, one end of the capillary communicates with the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com