Oil-free air compressor

A technology of air compressors and compressors, which is applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., can solve the problems of no consideration, lubricating oil infiltration, etc., and achieve the effect of reducing danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

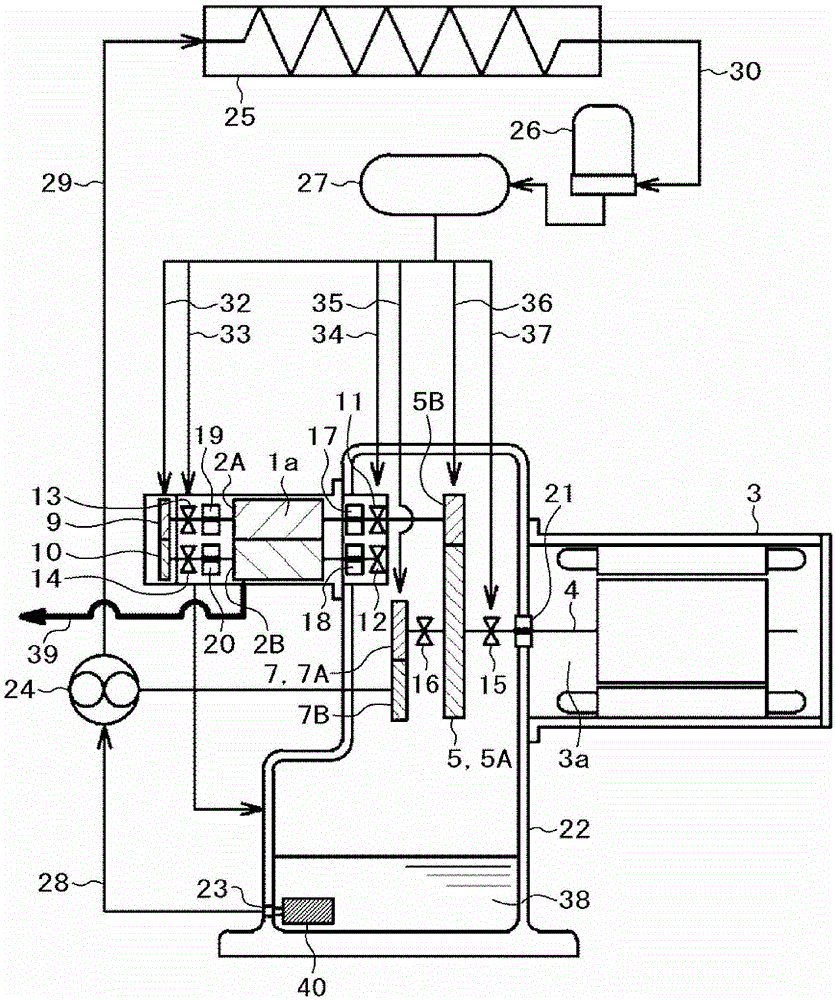

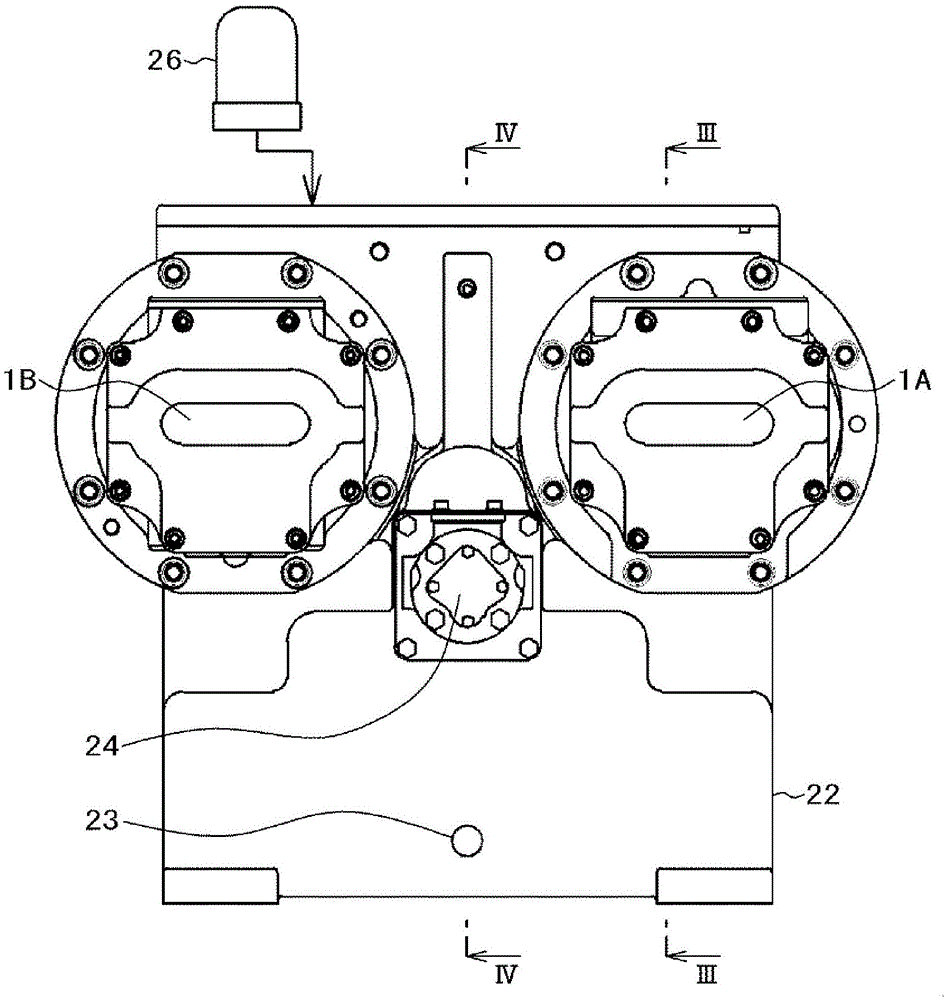

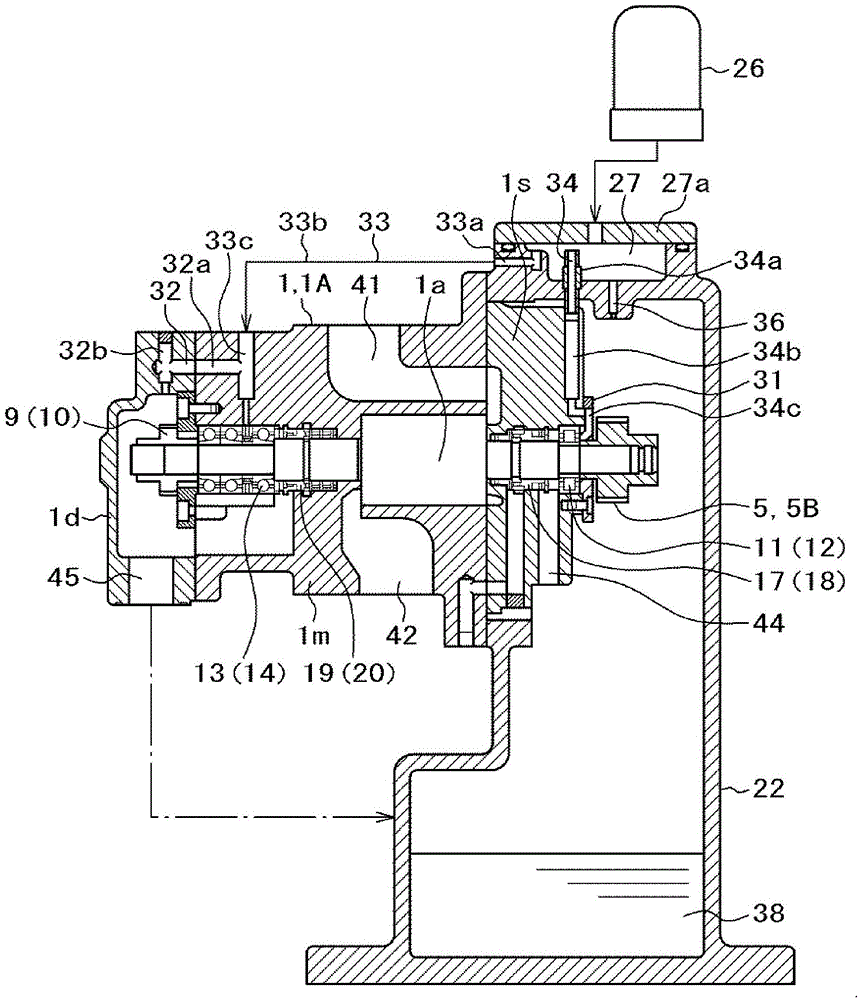

[0055] use Figure 1 to Figure 5 Example 1 of the present invention will be described. In this embodiment, an oil-free screw compressor will be described as an example of an oil-free air compressor (that is, an oil-free air compressor). In addition, in Figure 1 to Figure 5 In , the parts attached with the same reference numerals represent the same or corresponding parts.

[0056] figure 1 is a diagram illustrating the oil supply system of Embodiment 1 of the present invention, using the figure 1 The overall structure of this embodiment will be described.

[0057] exist figure 1 Among them, 1 is the main body of the compressor, and in the main body 1 of the compressor, a pair of male and female screw rotors (rotors) 2 (2A: male rotor, 2B: female rotor) engage to form a compression chamber 1a. In addition, the above-mentioned screw rotor (screw rotor) 2 is driven by the motor 3 via the motor shaft 4 and the compressor gear 5 (5A: drive gear, 5B: driven gear) to compress air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com