Turbo compressor and refrigerator using same

A turbo compressor and impeller technology, applied in the fields of turbo compressors and refrigerators, can solve the problems such as the increase of the vibration force of the motor rotor and the decrease of the self-excited vibration speed of the rotating shaft, so as to suppress the vibration, simplify the oil supply path, prevent the Effects of Electrocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

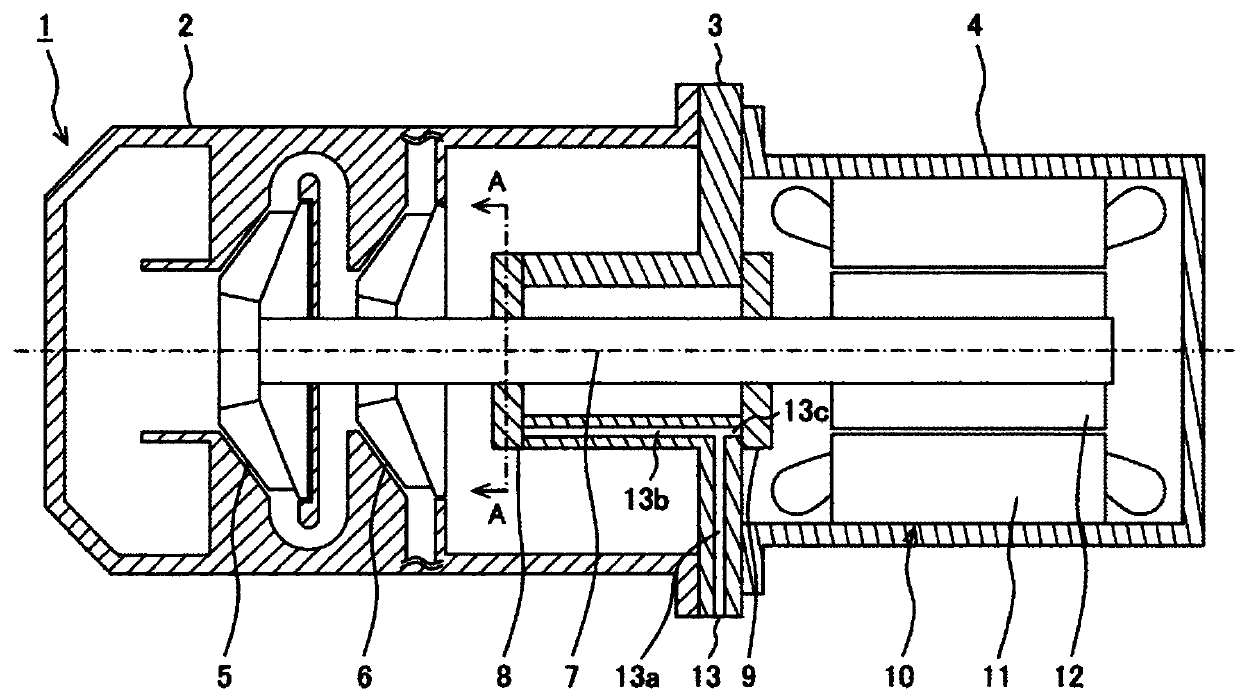

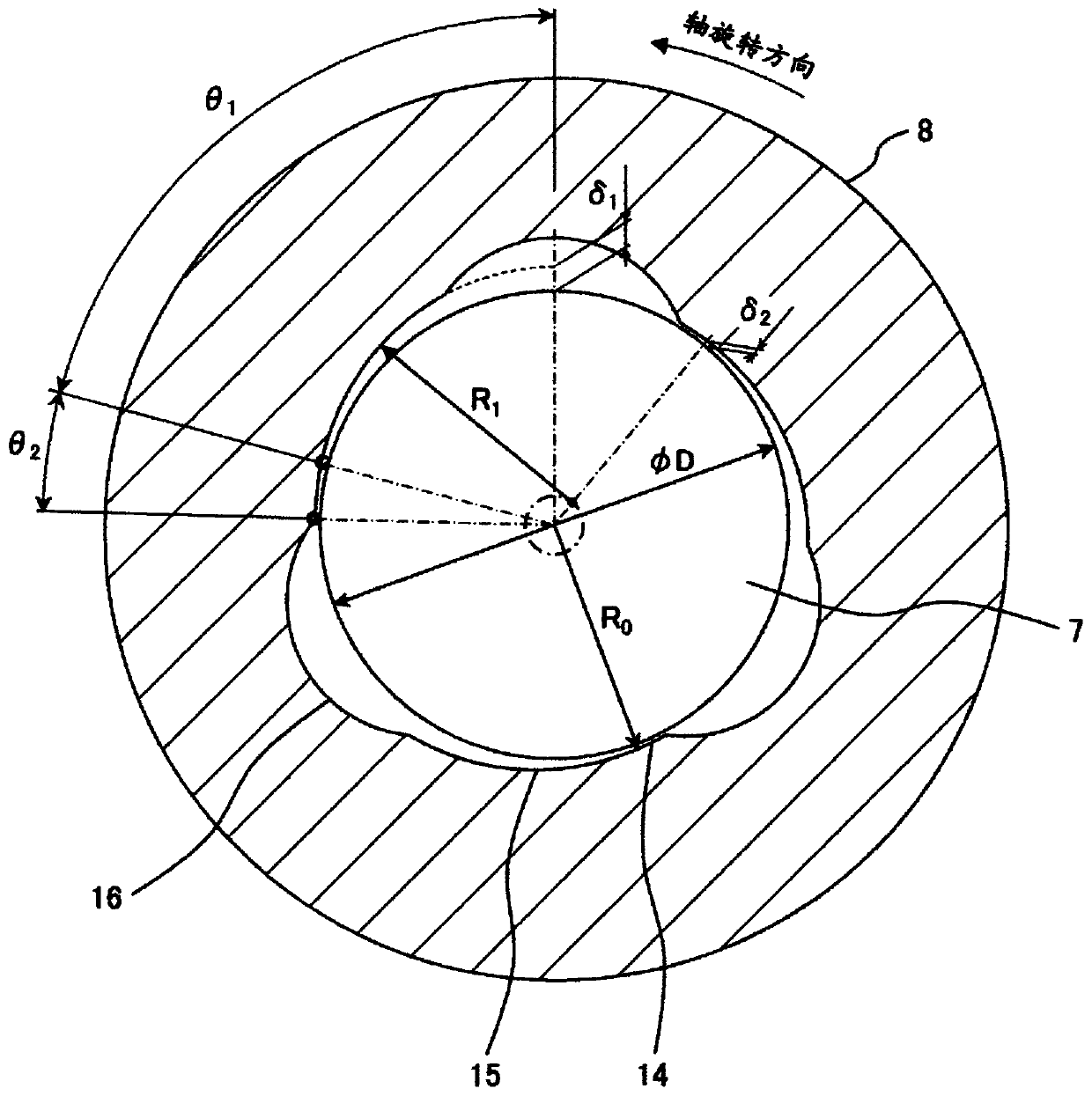

[0034] The present invention relates to a gearless turbo compressor which is a motor-direct type turbo compressor and a refrigerator using the turbo compressor. Here, the rotating shaft of the gearless turbo compressor is arranged in a substantially horizontal direction inside the casing, and is supported by a passive pressure sliding bearing.

[0035] Here, the "approximately horizontal direction" includes directions inclined by about 10 degrees with respect to the positive horizontal direction perpendicular to the direction of gravity. This is the reason for considering the installation environment when the turbo compressor is installed. Of course, such a small angle of inclination relative to the horizontal direction is better, preferably less than 5 degrees, more preferably less than 3 degrees. Regardless of the angle, the vibration of the rotating shaft can be suppressed by using the dynamic pressure sliding bearing (multi-arc sliding bearing) of the present invention. ...

Embodiment approach 2

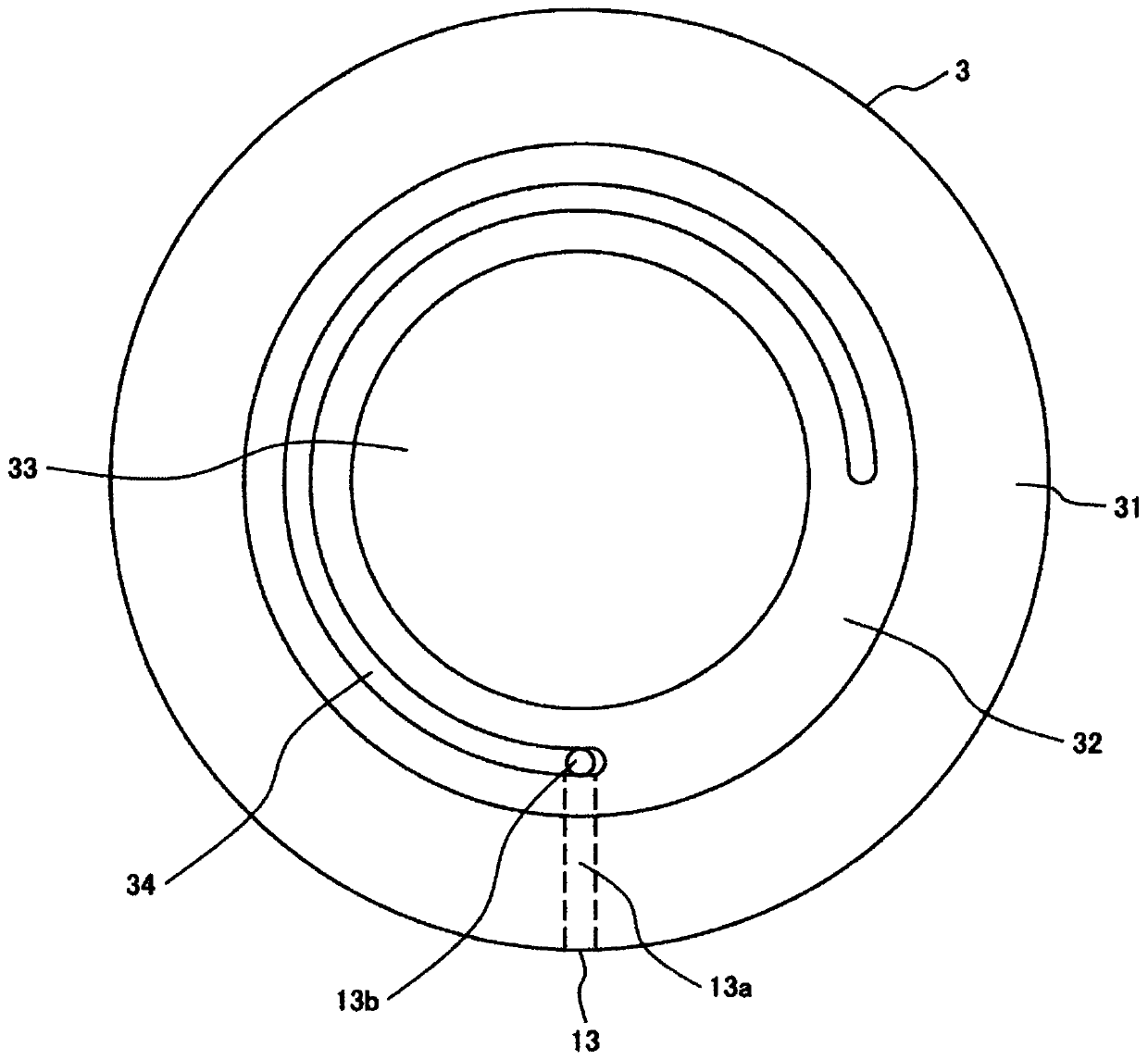

[0067] Figure 6 It is a schematic sectional view showing the overall structure of a turbo compressor according to another embodiment of the present invention.

[0068] In this figure with figure 1 A different aspect is that the bearing portion is constituted by the multi-arc sliding bearings 68 and 69 having small-diameter portions. The small-diameter portion is inserted into the bearing housing 3 . The bearing housing 3 has oil supply passages 13d and 13e connected to the oil supply passage 13b. The oil supply path 13d of the bearing housing 3 supplies lubricating oil to the small-diameter portion of the multi-arc sliding bearing 68 , and the oil supply path 13e of the bearing housing 3 supplies lubricating oil to the small-diameter portion of the multi-arc sliding bearing 69 .

[0069] Figure 7 is going Figure 6 The perspective view of the disassembled multi-arc sliding bearing 68 viewed from the side of the bearing housing 3 .

[0070] exist Figure 7 Among them, ...

Embodiment approach 3

[0074] Embodiments 1 and 2 have two bearings, both of which are multi-arc sliding bearings, but are not limited thereto, and one may be a perfect circular sliding bearing. exist Figure 9 An example of a perfect circular sliding bearing is shown in . The perfect circular plain bearing is set to the figure 1 Any one of the two bearings represented by symbols 8 and 9, the other is a multi-arc sliding bearing (for example, a three-arc bearing).

[0075] When at least one of them is a multi-arc sliding bearing, the effect of suppressing the wobbling of the rotary shaft can be obtained.

[0076] In addition, the multi-arc sliding bearing can accurately form the pressure distribution of the lubricating oil when the rotating shaft rotates forward. In addition, when the compressor suddenly stops, the rotating shaft is temporarily reversed due to the reverse flow of the refrigerant gas, and the above-mentioned effects of the multi-arc sliding bearing may not be sufficiently obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com