Hydraulic clutch

A hydraulic clutch and clutch technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of faster rotation of the main shaft, larger drag torque, and larger shifting noise, and reduce shifting. sound, simplify the oil supply path, and prevent the effect of dragging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

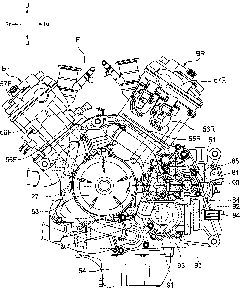

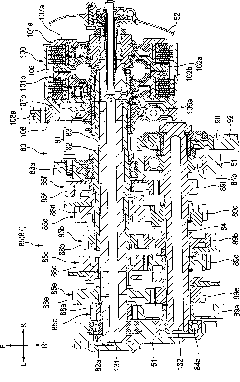

[0053] Hereinafter, an embodiment of the hydraulic clutch of the present invention will be described in detail with reference to the drawings. In addition, the drawings are viewed according to the direction of the reference signs. In the following description, the front and rear, left and right, and up and down are based on the direction observed by the operator. In the figure, the front of the vehicle is referred to as Fr, the rear as Rr, and the left as L , Let the right side be R, the upper side as U, and the lower side as D.

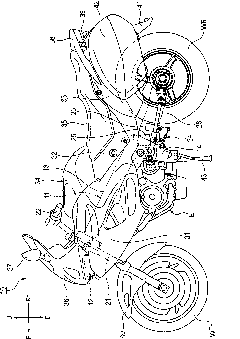

[0054] First, like figure 1 As shown, the body frame 11 of the motorcycle 10 has: a head pipe 12 provided at the front end; a pair of left and right main frames 13 extending backward and downward from the head pipe 12; and a pair of left and right main frames 13 connected to the rear. A pair of left and right pivot plates 14 extending downward.

[0055] In addition, the motorcycle 10 has: a front fork 21 supported on the head pipe 12 in a steerable manne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com