Push-pull type self-locking connector

A connector, push-pull technology, applied in the direction of connection, two-part connection device, parts of connection device, etc., can solve the problem of unreliable locking of quick-plug connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

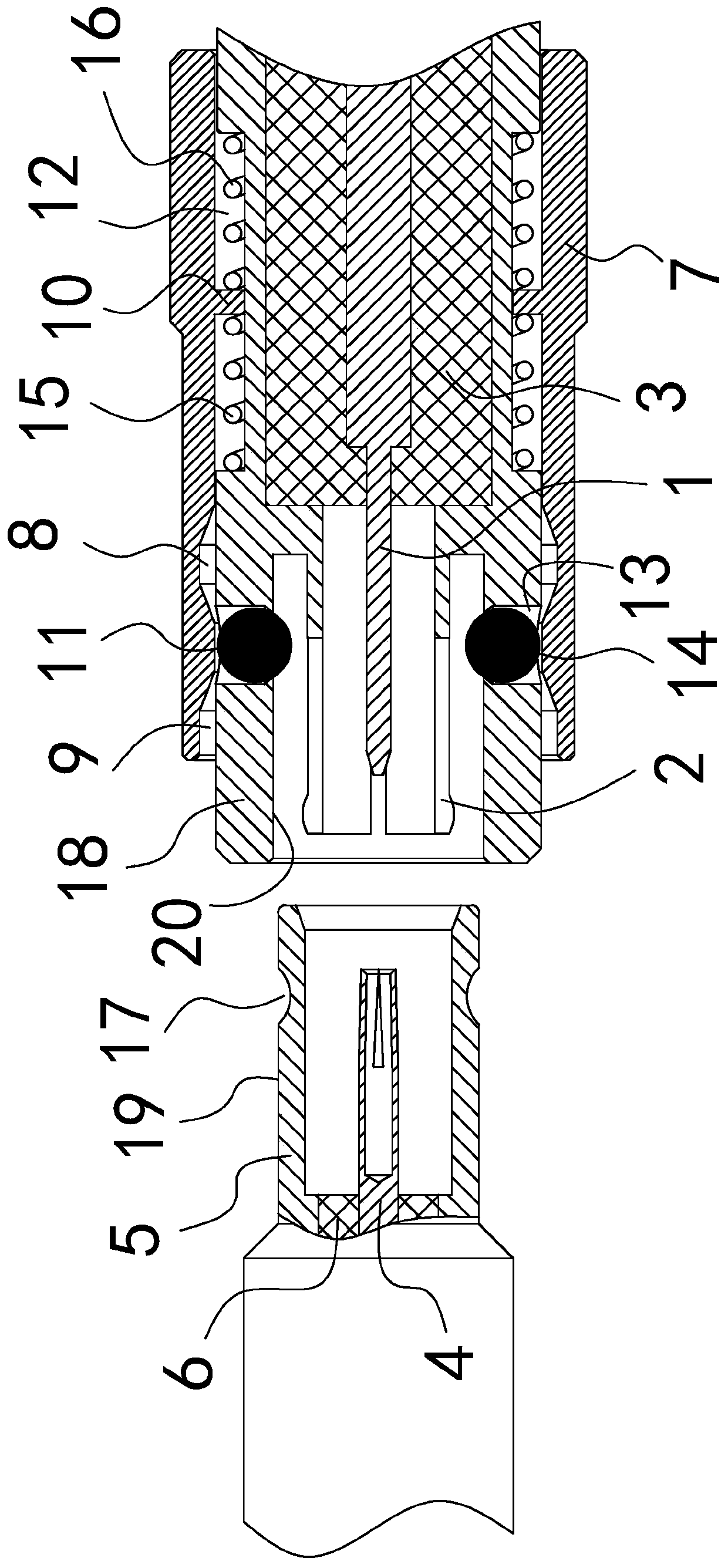

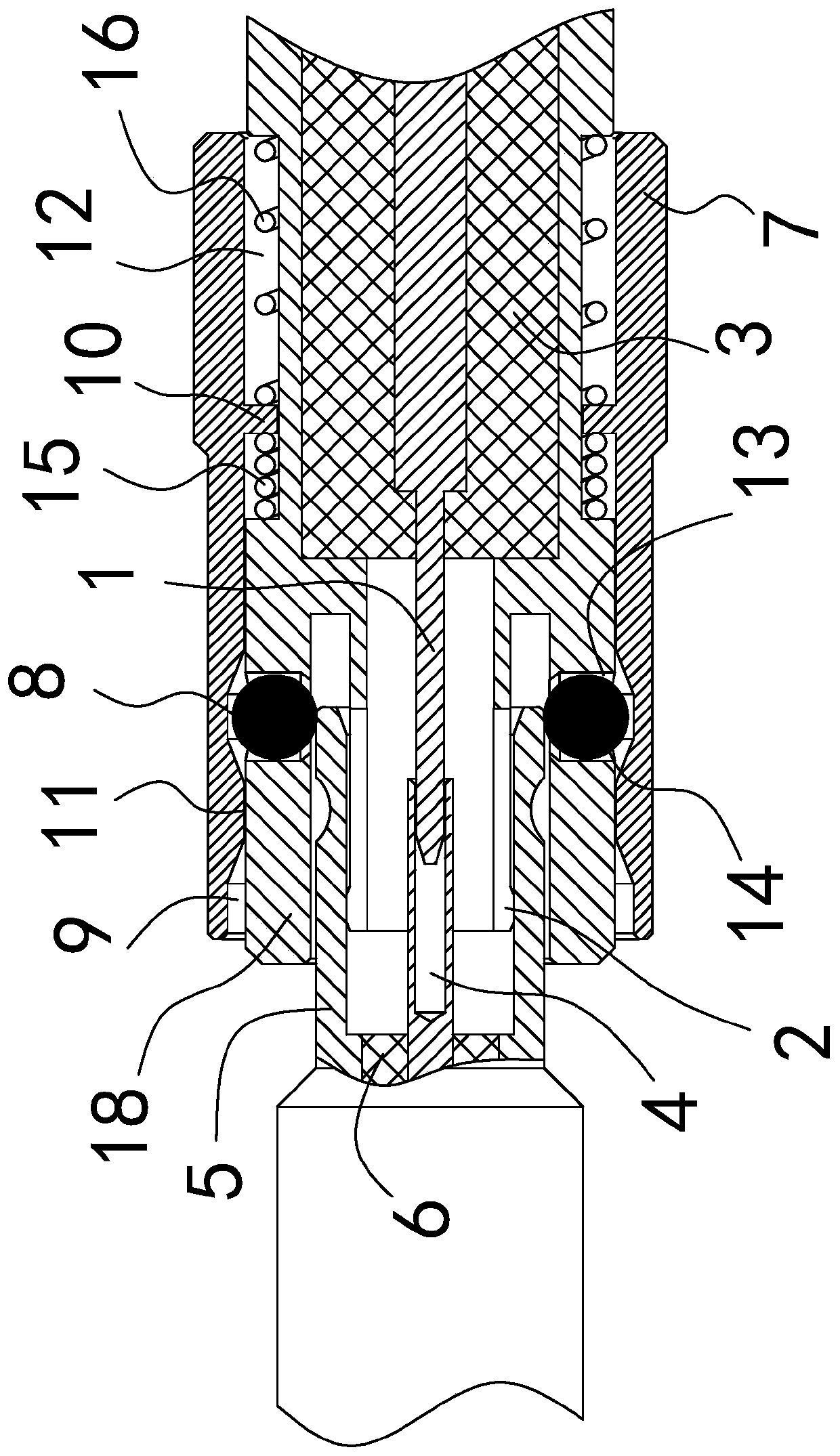

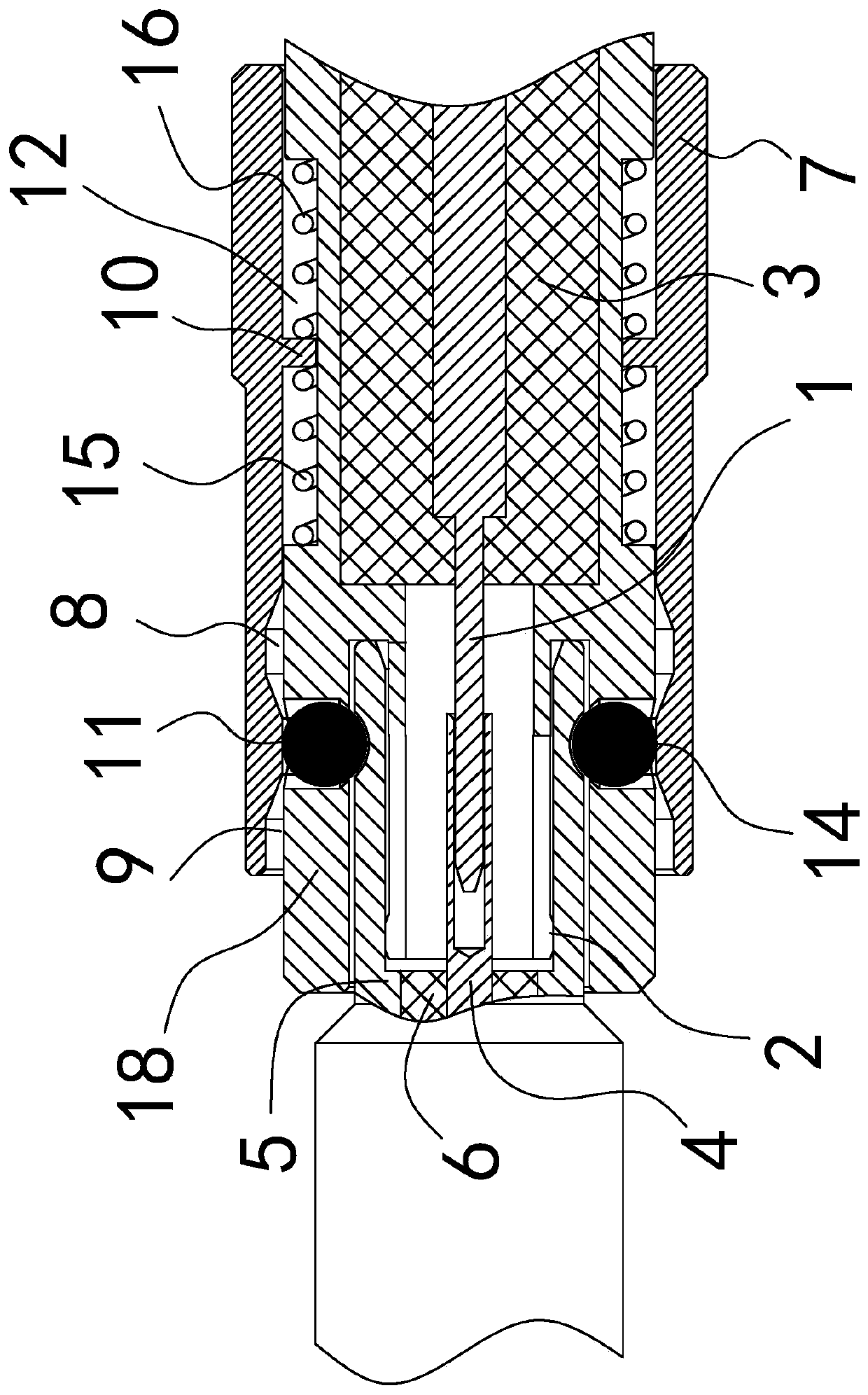

[0022] Example: a push-pull self-locking connector

[0023] Such as figure 1 As shown, the connector consists of male and female.

[0024] The male head is composed of a male head inner conductor 1, a male head outer conductor 2, a male head insulator 3, a lock sleeve 7, a lock ball 14, a first spring 15 and a second spring 16 (see figure 1 right half). Wherein, the male insulator 3 is located between the male inner conductor 1 and the male outer conductor 2 for supporting and isolating the male inner conductor 1 and the male outer conductor 2, and the male insulator 3 is an electrical insulating medium. The male inner conductor 1 is a pin, which is used to intermate with the female socket to form a connection. The mating end surface of the male outer conductor 2 is provided with a slotted structure for fully contacting with the female outer conductor 5 to form an electrical connection. The outer conductor 2 of the male head is provided with a jacket 18 (see figure 1 ), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com