Machine tool chip removal cleaning device for numerical control machine tool

A technology of CNC machine tools and cleaning devices, which is applied to metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of poor cleaning effect, inability to classify waste and collection, and inability to recycle cleaning fluid, etc. High universality, simple and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

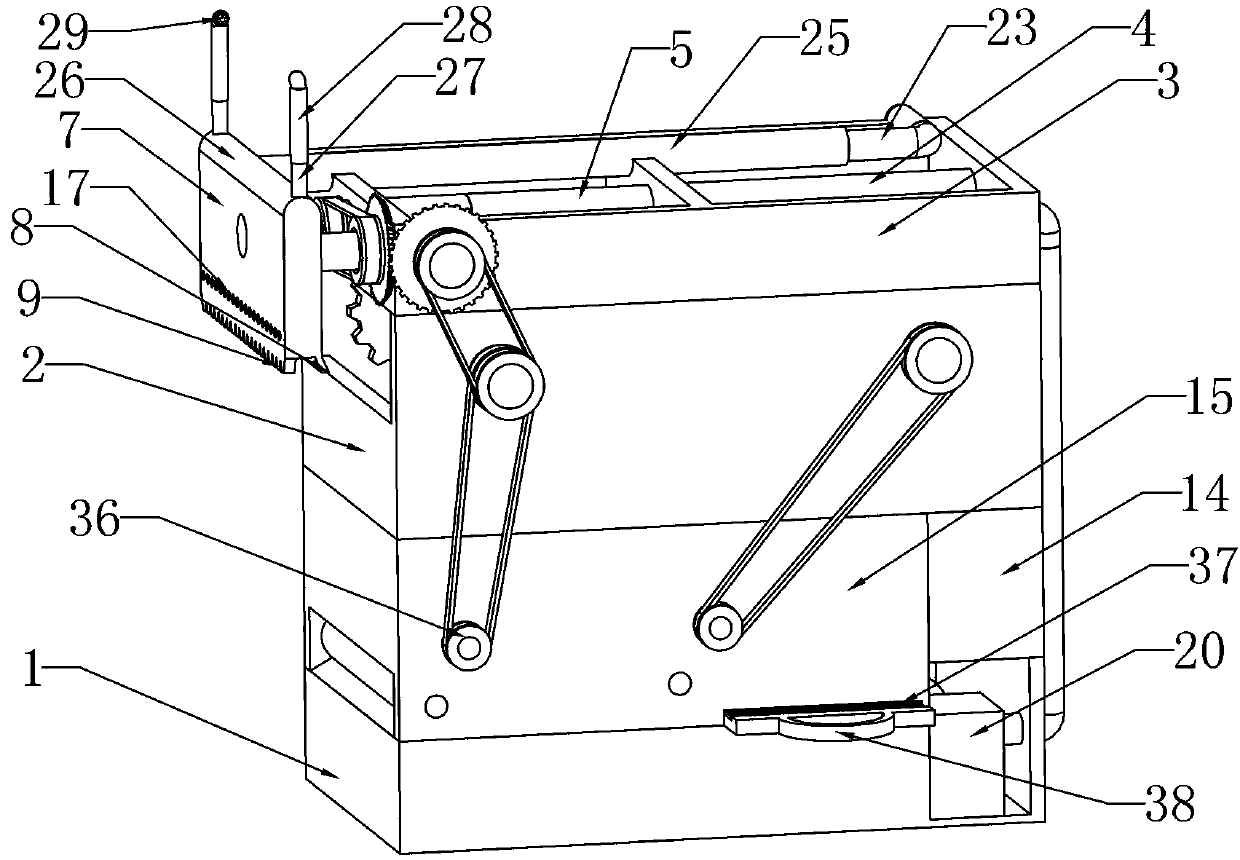

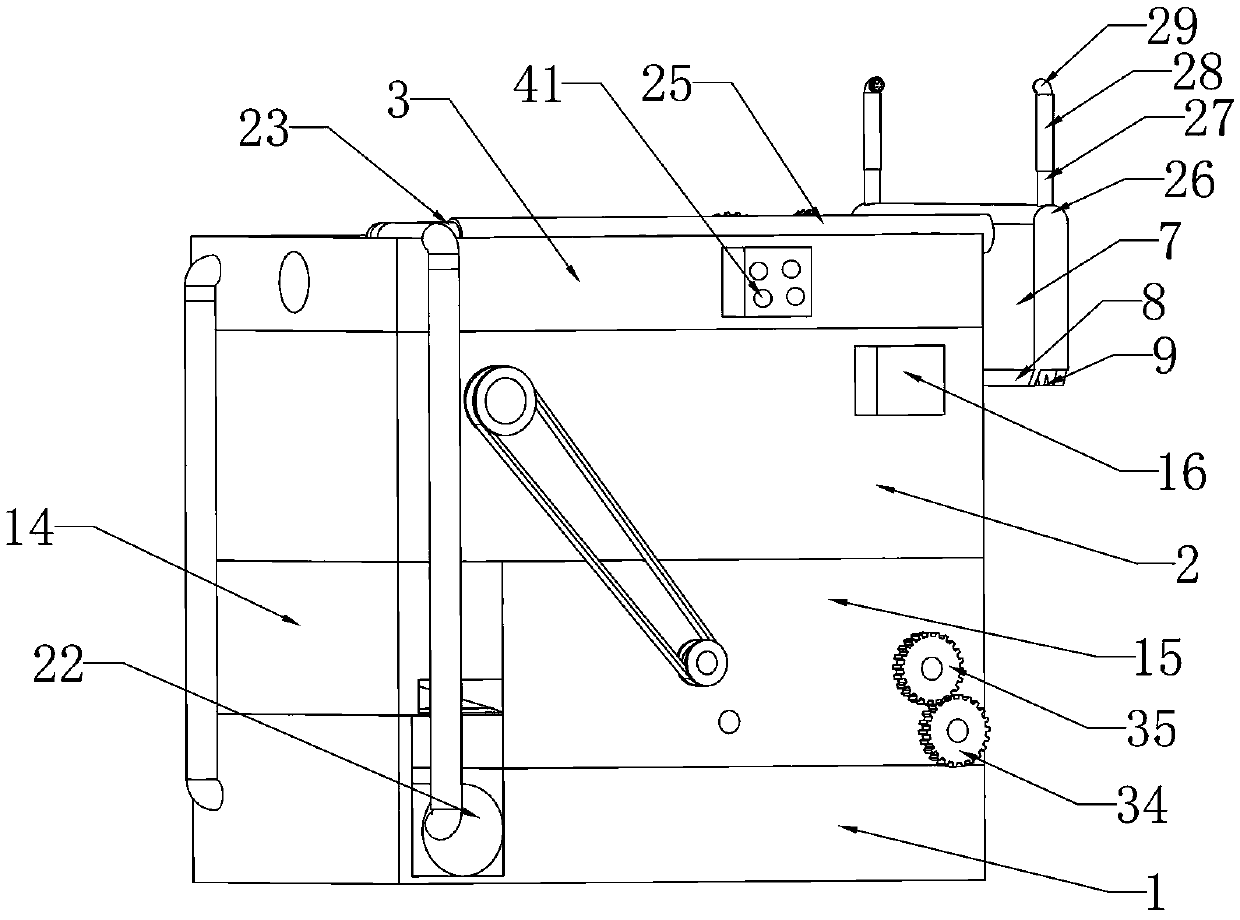

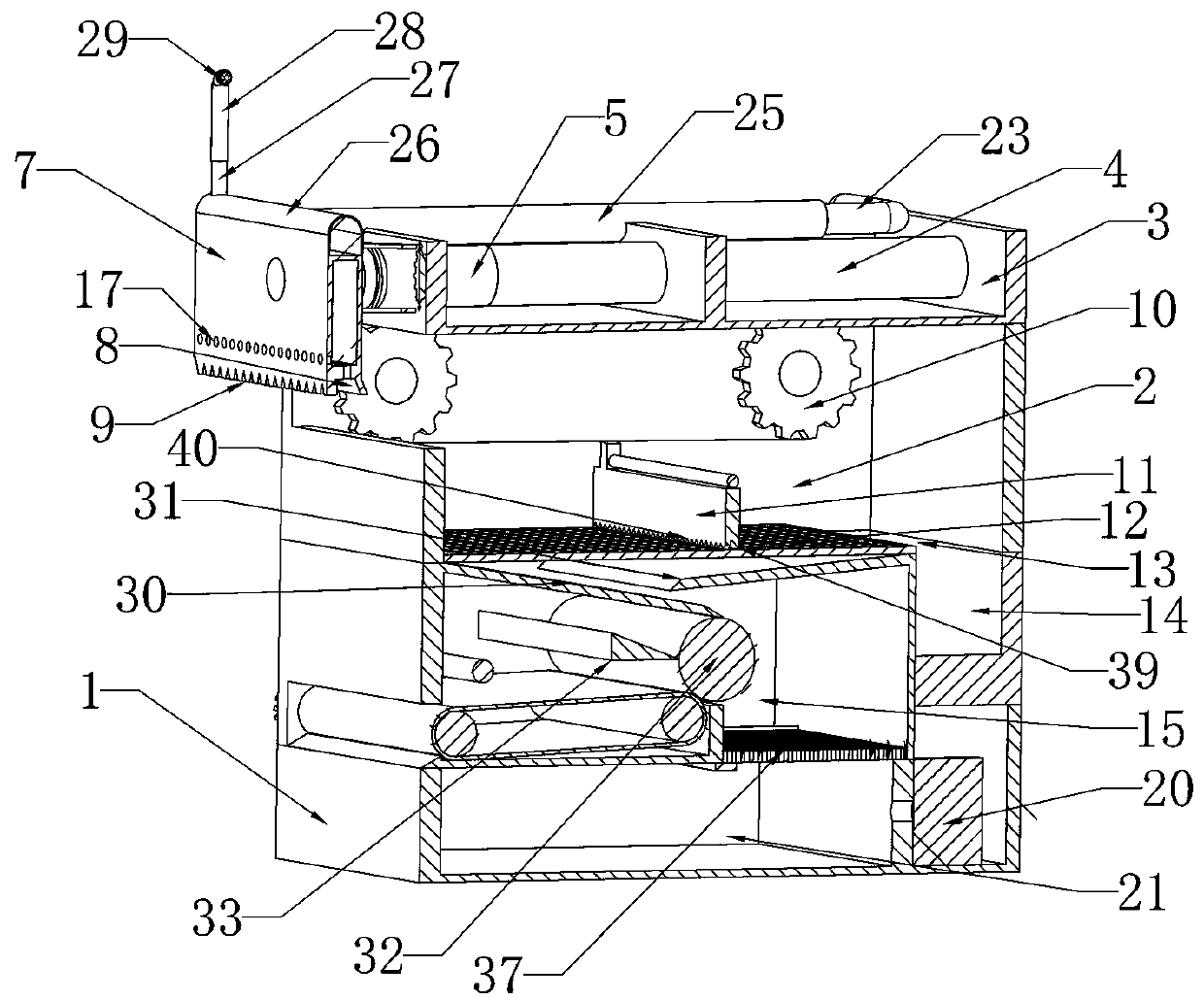

[0038] Embodiment 1. The present invention is a chip removal and cleaning device for a CNC machine tool, which includes a base 1 and a primary collection chamber 2 placed above the base 1. The base 1 provides fixed support for the subsequent structure. The first-level collection chamber 2 collects waste, and it is characterized in that the upper end of the first-level collection chamber 2 is fixedly connected with a telescopic bracket 3, and the telescopic bracket 3 is fixedly connected with a telescopic sleeve 4. The left end of the telescopic sleeve 4 is rotatably connected with a telescopic threaded sleeve 5, and the coaxial thread of the telescopic sleeve 5 is fitted with a reciprocating screw 6. The telescopic sleeve 4 is hollow, so that the reciprocating screw 6 is The telescopic threaded sleeve 5 can reciprocally slide along the telescopic sleeve 4 during the rotation process, and the left end of the reciprocating screw 6 is fixedly connected with a scraper 7, and the re...

Embodiment 2

[0043] Embodiment 2, on the basis of Embodiment 1, in the process of cleaning the CNC machine tool, only the scraper 7 is used for cleaning, the cleaning effect is limited, and the debris adhering to the CNC machine tool and the CNC machine tool cannot be removed The remaining debris above the machine tool is removed in time, so this embodiment provides a structure for efficient cleaning. Specifically, the scraper 7 is provided with a water passage, and the lower end and left end of the scraper 7 are provided with water spray Holes 17, through the water spray holes 17, spray cleaning fluid into the CNC machine tool to clean the inner wall of the CNC machine tool. The water spray holes 17 are distributed in multiples to ensure that the bottom of the CNC machine tool can be thoroughly cleaned. Cleaning to avoid debris residue, the water channel is connected to the secondary telescopic water pipe 18 fixedly connected to the right end of the scraper 7, and the secondary telescopic ...

Embodiment 3

[0045] Embodiment 3, on the basis of Embodiment 2, in order to clean the cleaning solution again, ensure the cleanliness of the cleaning solution, and improve the purity of the cleaning solution, this embodiment provides a method for cleaning the tiny debris mixed in the cleaning solution. device, the upper end of the waste liquid bin 15 is fixedly connected with a left deflector 30 and a right deflector 31, and there is a gap between the left deflector 30 and the right deflector 31 to ensure that the cleaning liquid can pass through The left deflector 30 and the right deflector 31 enter the waste liquid bin 15, and the lower end of the left deflector 30 is in contact with a magnetic roller rotatably connected in the waste liquid bin 15 32. Make the cleaning solution passing through the left deflector 30 flow through the magnetic roller 32 to the right half of the magnetic roller, in order to ensure that the magnetic roller 32 can better clean the debris in the cleaning solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com