CRT television set disassembly line

A CRT TV, dismantling table technology, applied in the direction of electronic waste recycling, smoke removal, recycling technology, etc., can solve the problem of increasing the workload of intermediate material conveying belts, unfavorable sorting quality and sorting efficiency, and increasing sorting. It can solve the problems of personnel labor intensity and other problems, and achieve the effect of solving the uneven supply of raw materials, realizing automatic sorting and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

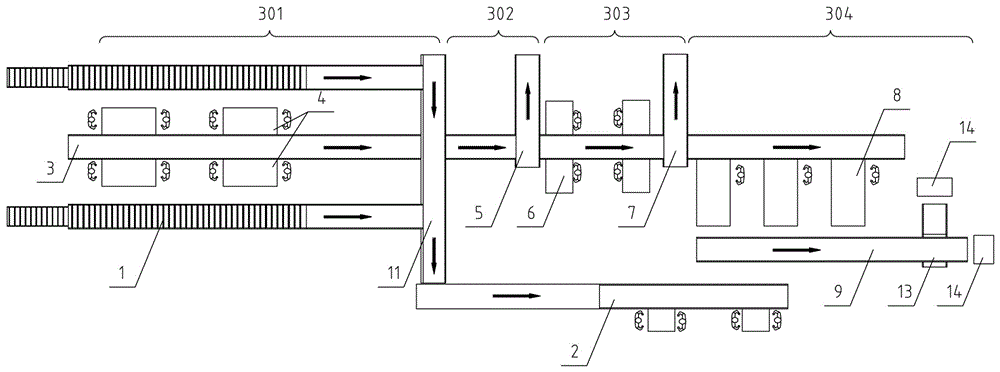

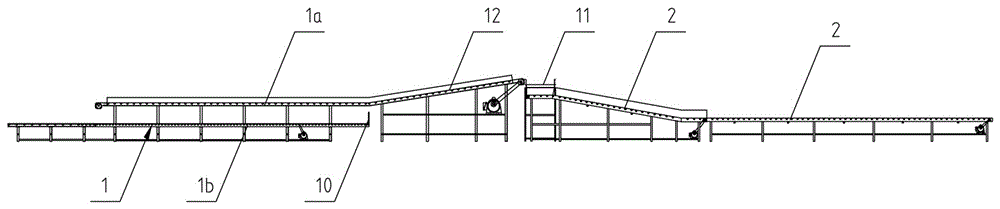

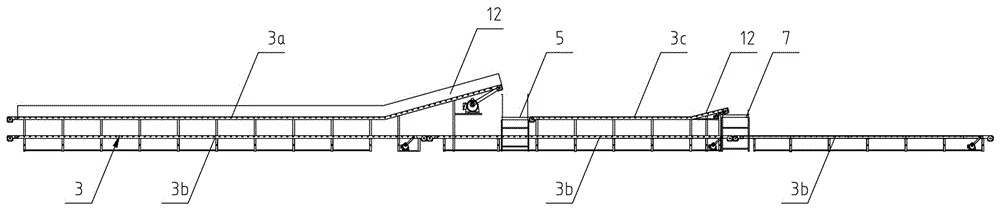

[0035] see figure 1 , figure 2 , image 3 , Figure 4 , the present invention includes at least one material conveying line 1, and the material conveying line 1 is made up of upper layer parts conveying line 1a and lower floor CRT television conveying line 1b, and the tail end of parts conveying line 1a is connected parts sorting line 2; There are several main dismantling lines 3 arranged in parallel on one side of the material conveying line 1, and the main dismantling lines 3 are arranged in sequence along the conveying direction as a dismantling area 301 for realizing the dismantling of the plastic case, CRT and corresponding parts, and the plastic case Recycling area 302, explosion-proof belt cutting area 303, CRT cutting area 304; In dismantling area 301, plastic shell recycling area 302, main dismantling line 3 is all made up of upper floor plastic shell conveying line 3a and lower floor CRT conveying line 3b, wherein The dismantling area 301 is provided with several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com