Green and environment-friendly prefabricated inner wallboard and manufacturing method thereof

A green and environmental protection, interior wall panel technology, applied in the field of building materials, can solve the problems of short service life of prefabricated interior wall panels, comprehensive damage of prefabricated interior wall panels, accelerated freeze-thaw damage, etc., so as to be beneficial to environmental protection and reduce self-weight. , reduce the effect of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

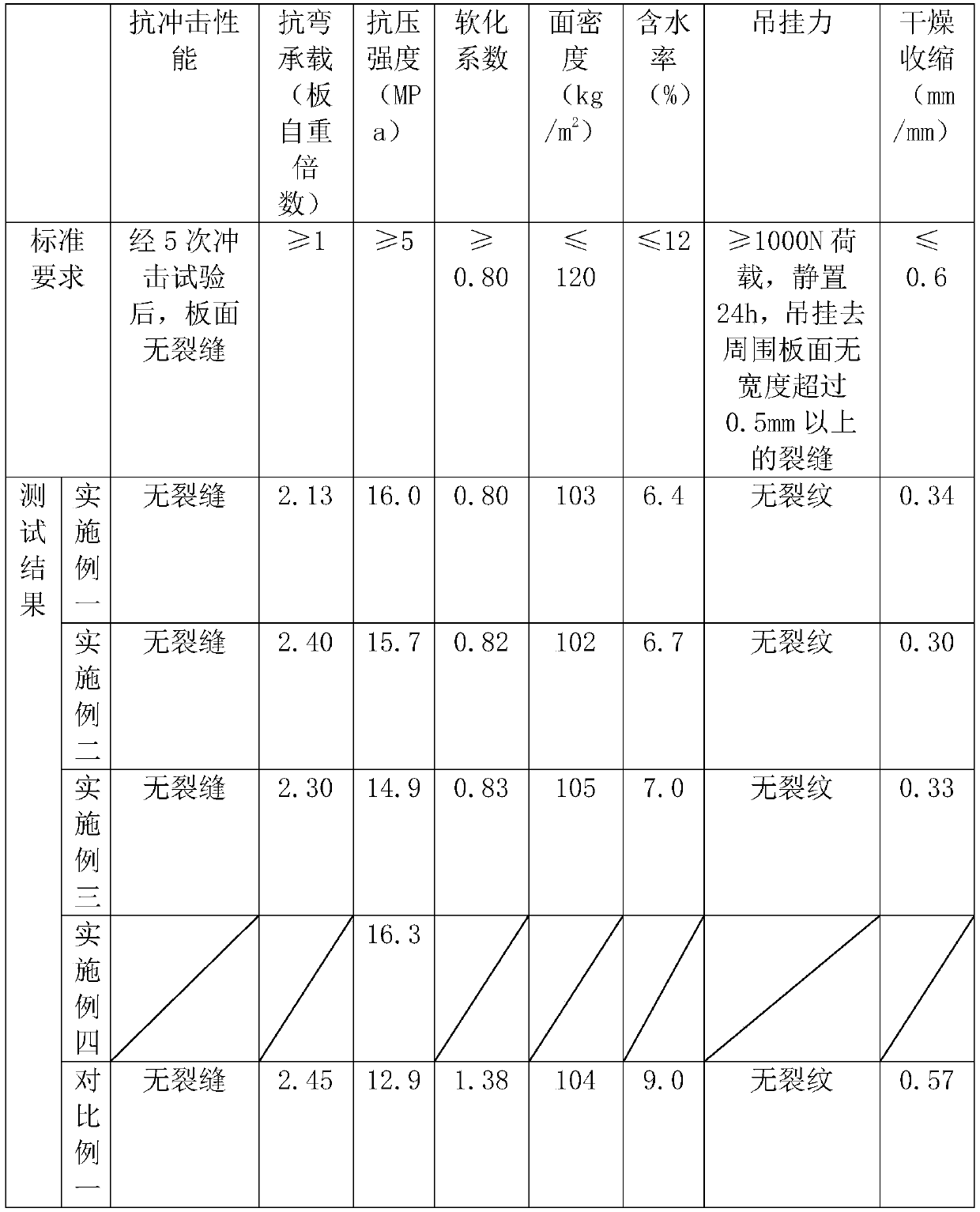

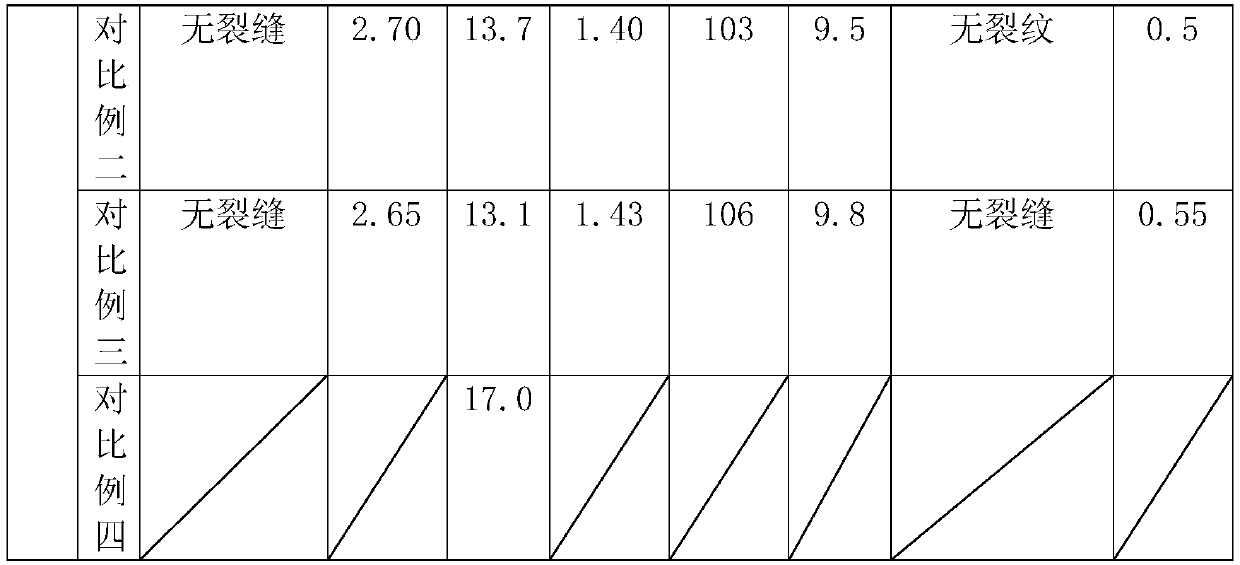

Embodiment 1

[0039] Firstly, the bought coal slag is crushed through a grinder, and then the coal slag with a particle size of 1.5-1.7mm is screened out; secondly, the building slag is first crushed with a crusher, and then the crushed building slag is ground with a grinder, and finally Screen out construction slag with a particle size of 3-3.5mm; again, select sand with a particle size of 0.25-0.28; weigh 20 parts of 42.5R low-alkali sulfoaluminate micro-expansion cement, 8 parts of sand, 8 parts of cinder and 64 1 part of building slag for preliminary mixing, then add 20 parts of water, and use a mixer to stir for 15 seconds, then extrude the mixed concrete into a prefabricated mold through a mobile extruder for static hardening of the slab, and when the slab is hardened, the slab The slab was released from the mold, and then transported to the curing field for 15 days of curing under natural conditions, and then a sample of 2470×600×90mm was taken out from the slab, and the test was carr...

Embodiment 2

[0041]Firstly, the bought coal slag is crushed through a grinder, and then the coal slag with a particle size of 1.5-1.7mm is screened out; secondly, the building slag is first crushed with a crusher, and then the crushed building slag is ground with a grinder, and finally Screen out construction slag with a particle size of 3-3.5mm; again, select sand with a particle size of 0.25-0.28; weigh 25 parts of 42.5R low-alkali sulfoaluminate micro-expansion cement, 5 parts of sand, 7.8 parts of cinder and 62.2 parts 1 part of building slag for initial mixing, then add 20 parts of water, use a mixer to stir for 15 seconds, observe the flow state of the concrete, record the results as shown in Table 2, and then squeeze the mixed concrete into the prefabricated mold through a mobile extruder Carry out static hardening of the slab. When the slab is hardened, the slab is released from the mold, and then transported to the curing field for 15 days of curing under natural conditions, and th...

Embodiment 3

[0043] Firstly, the bought coal slag is crushed through a grinder, and then the coal slag with a particle size of 1.5-1.7mm is screened out; secondly, the building slag is first crushed with a crusher, and then the crushed building slag is ground with a grinder, and finally Screen out construction slag with a particle size of 3-3.5mm; again, select sand with a particle size of 0.25-0.28; weigh 27 parts of 42.5R low-alkali sulfoaluminate micro-expansion cement, 4 parts of sand, 7.7 parts of cinder and 61.3 1 part of building slag for preliminary mixing, then add 20 parts of water, and use a mixer to stir for 15 seconds, then extrude the mixed concrete into a prefabricated mold through a mobile extruder for static hardening of the slab, and when the slab is hardened, the slab The slab was released from the mold, and then transported to the curing field for 15 days of curing under natural conditions, and then a sample of 2470×600×90mm was taken out from the slab, and the test was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com