An integrated system for in-situ stress detection and repair

An integrated system, in-situ stress technology, applied in the direction of force measurement, process efficiency improvement, material magnetic variables, etc. by measuring the change of magnetic properties of materials caused by applied stress, which can solve the problem of in-situ stress relief and repair that are not suitable for application Process, can not completely eliminate the stress and other problems, to achieve the effect of saving labor costs, eliminating ring effects, and avoiding human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

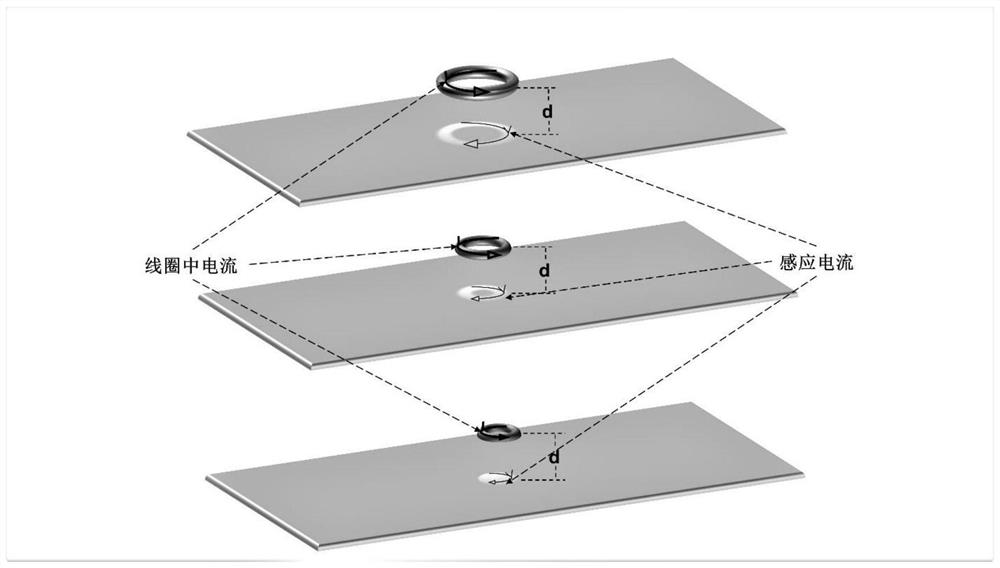

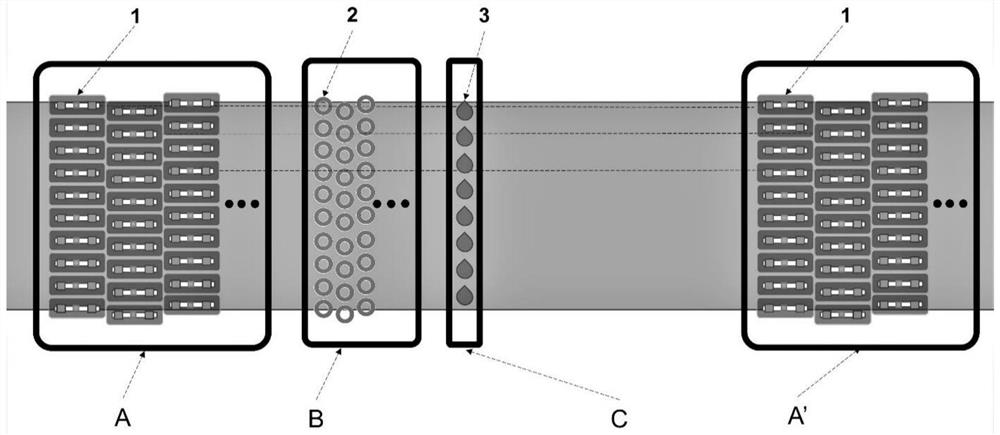

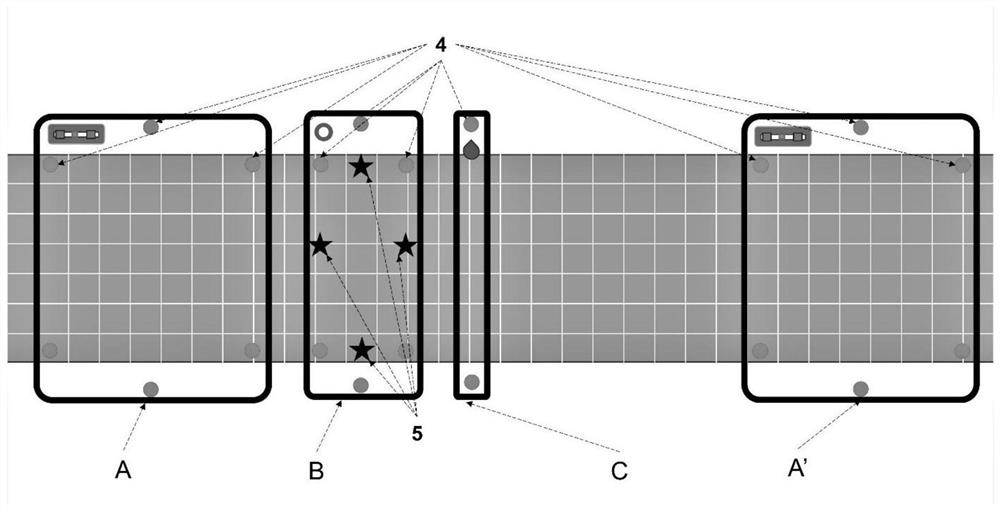

[0037] This embodiment uses circular induction heating coils. The diameter D and eddy current distribution of the electromagnetic induction coil largely depend on the distance between the coil and the surface of the steel to be treated. When the induction coil is far away from the surface of the ferromagnetic steel, the eddy current induced by it forms a magnetic ring with thickness r, and as D becomes smaller, the eddy current distribution follows the 1 / d law, and d is the distance between the coil and the ferromagnetic steel. Increasing the distance d between the coil and the material is beneficial to the heat treatment of the micro-unit steel, thereby improving the stress recovery effect in the corresponding range. However, considering the cost and reducing energy consumption, according to the "ring effect", such as figure 1 As shown, that is, the eddy current distribution is mainly concentrated at the boundary of the range under the coil radiation, forming an eddy current...

Embodiment 2

[0044] For the detection and repair of steel with special dimensions and special shapes in industrial production, different coil shapes can be specially made by redesigning the shape of the induction heating coil. In this implementation for miniaturized production or single point stress repair heat treatment, if Figure 4 As shown, the induction heating coil 2 is a V-shaped coil, and the ferromagnetic steel below is heat-treated by means of the V-shaped vertex S. In addition, the entire integrated system of this embodiment can be as shown in Embodiment 1, which will not be repeated here.

[0045] The present invention is further illustrated below by describing a method for in-situ inspection and repair using the integrated system of the present invention. Briefly summarized, the workflow of the integrated system of the present invention is: Stress detection by the stress detection module, positioning by the infrared locator, computer drawing of a virtual coordinate system → r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com