Transformer monitoring system

A technology for monitoring systems and transformers, which is applied in closed-circuit television systems, supporting machines, and control without feedback. It can solve the problems of lack of effective monitoring of transformers, untimely handling of small faults, and major accidents, etc., and achieve simple structure and wide monitoring range. Comprehensive, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

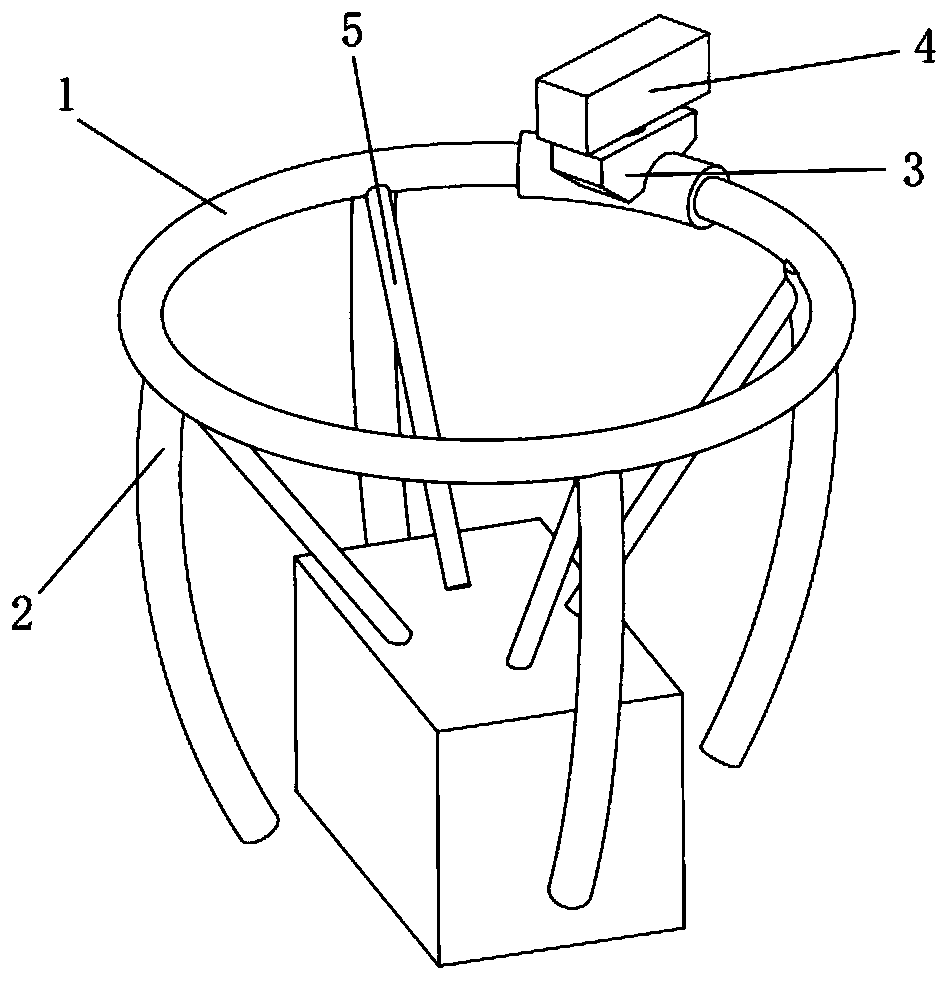

[0019] Such as figure 1 As shown, a schematic diagram of a transformer monitoring system.

[0020] Four supporting rods 5 are connected to the top of the transformer, and the upper ends of the supporting rods 5 are connected to the bottom of the main rail 1 for fixing the main rail 1 . The material of the support rod 5 can be selected from stainless steel, which is light in weight, good in rigidity and corrosion-resistant. The main track 1 is a circular closed track. The camera device is movably connected to the main rail 1. The junction of the extended guide rail 2 and the main guide rail 1 is connected in an arc shape, and the end of the extended guide rail 2 is level with the bottom of the oil tank of the transformer. The arc connection between the extension guide rail 2 and the main guide rail 1 can facilitate the camera device to enter the extension guide rail 2 from the main guide rail 1 or retreat from the extension guide rail 2 to the main guide rail 1 . The end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com