Stator core and motor

A stator core and iron core technology, applied in the prevention/reduction of eddy current loss in the winding head, magnetic circuit shape/style/structure, electrical components, etc., can solve problems such as magnetic flux loss, and achieve the goal of reducing magnetic flux loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

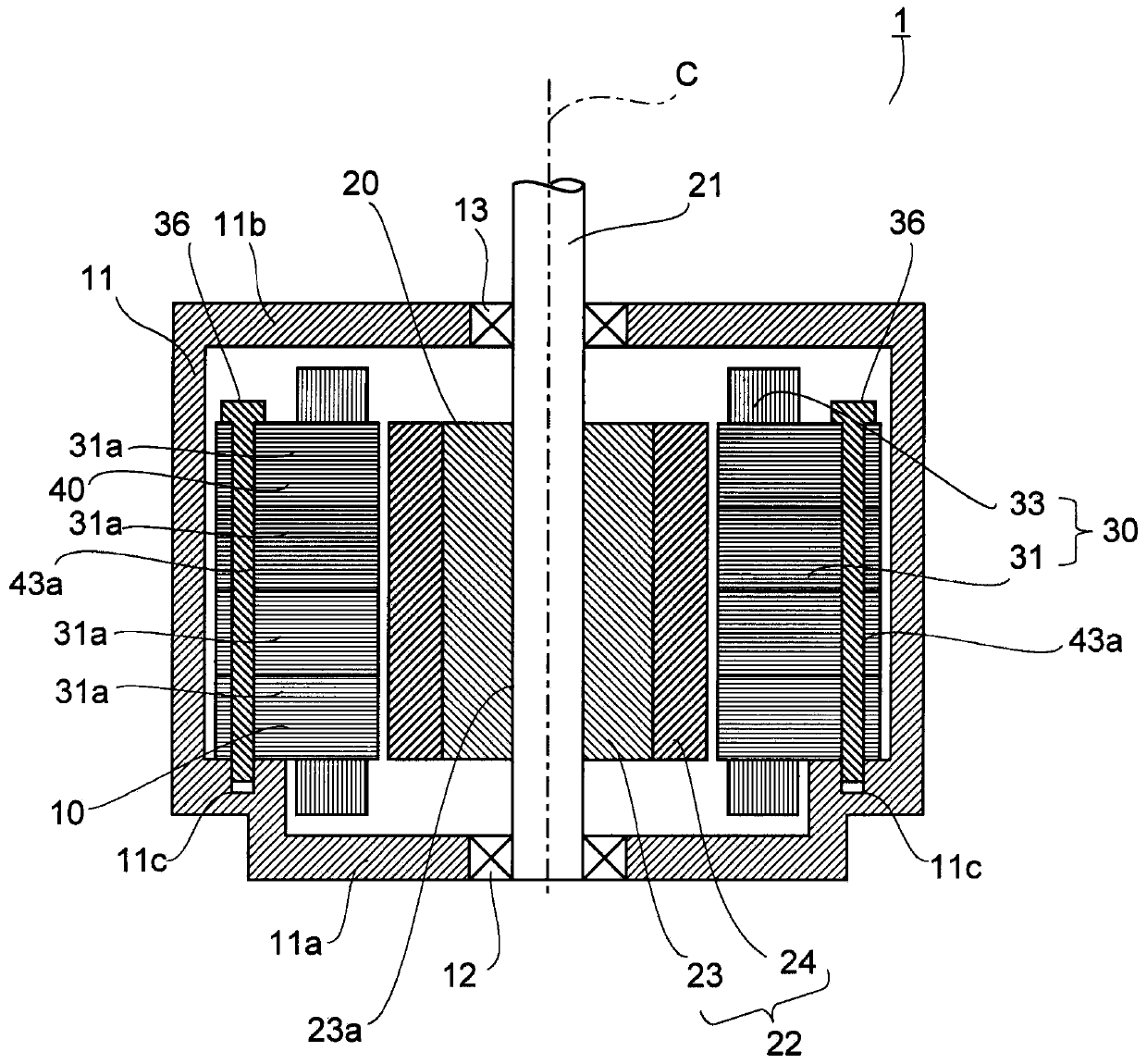

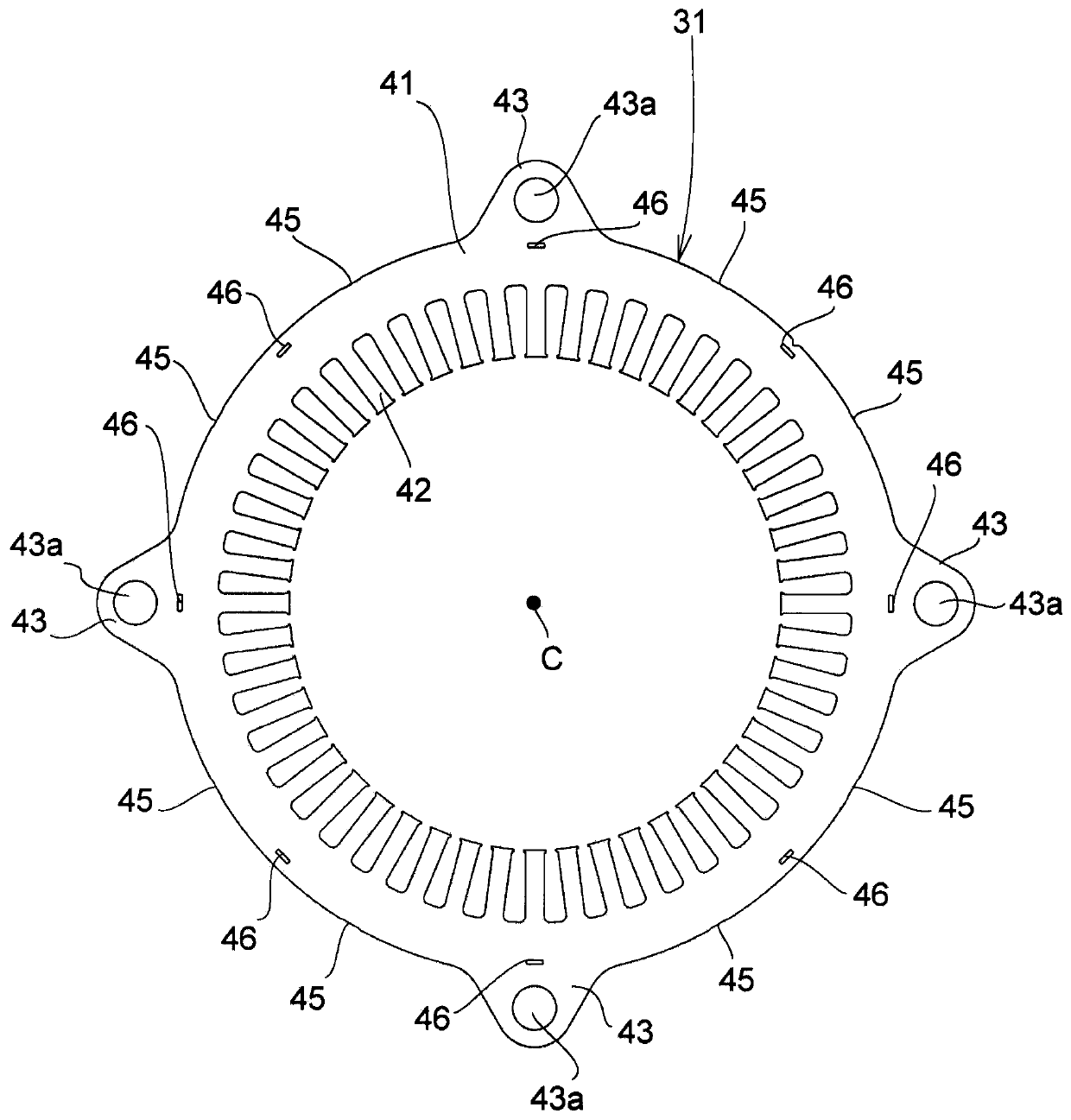

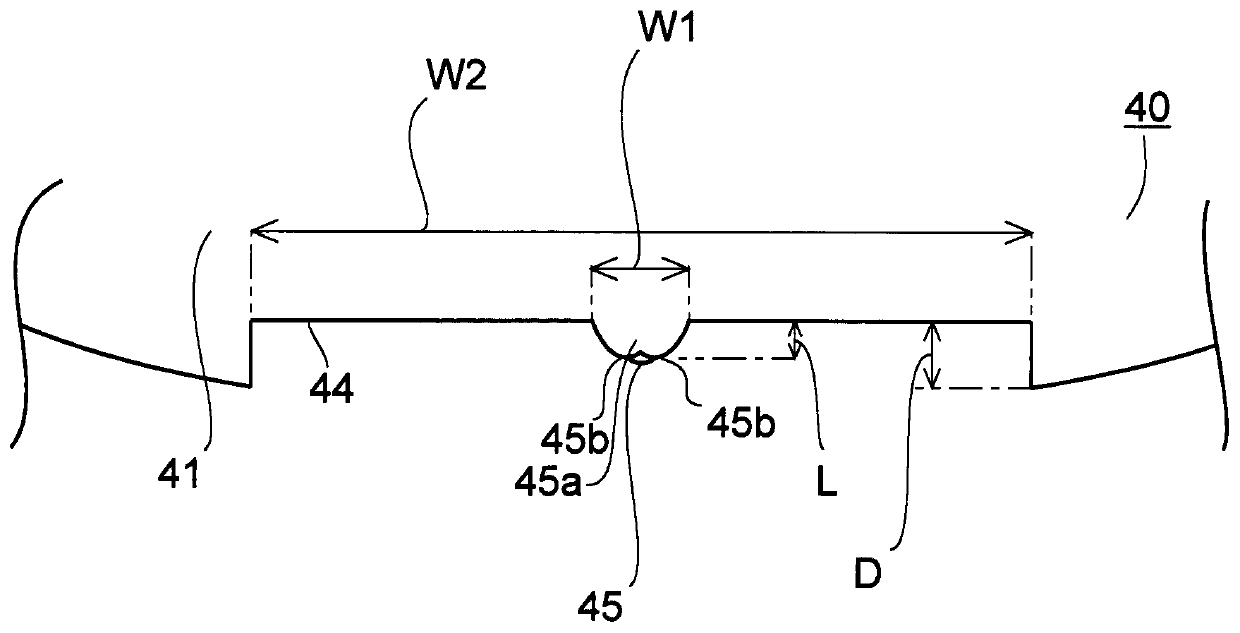

[0015] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the drawings. In this specification, the upper side in the central axis direction of the motor is referred to as "upper side", and the lower side is referred to as "lower side". In addition, the up-down direction does not indicate the positional relationship or direction when assembled in an actual device. In addition, the direction parallel or substantially parallel to the central axis is referred to as "axial direction", the radial direction centered on the central axis is simply referred to as "radial direction", and the circumferential direction centered on the central axis is referred to as "circumferential direction". Towards". In addition, in this specification, the shape and positional relationship of each part are demonstrated using the axial direction as an up-down direction, and the top plate part 11b side as an upper direction with respect to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com