A bottle body swelling detection device

A detection device and bottle body technology, applied in sorting and other directions, can solve problems such as inconvenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

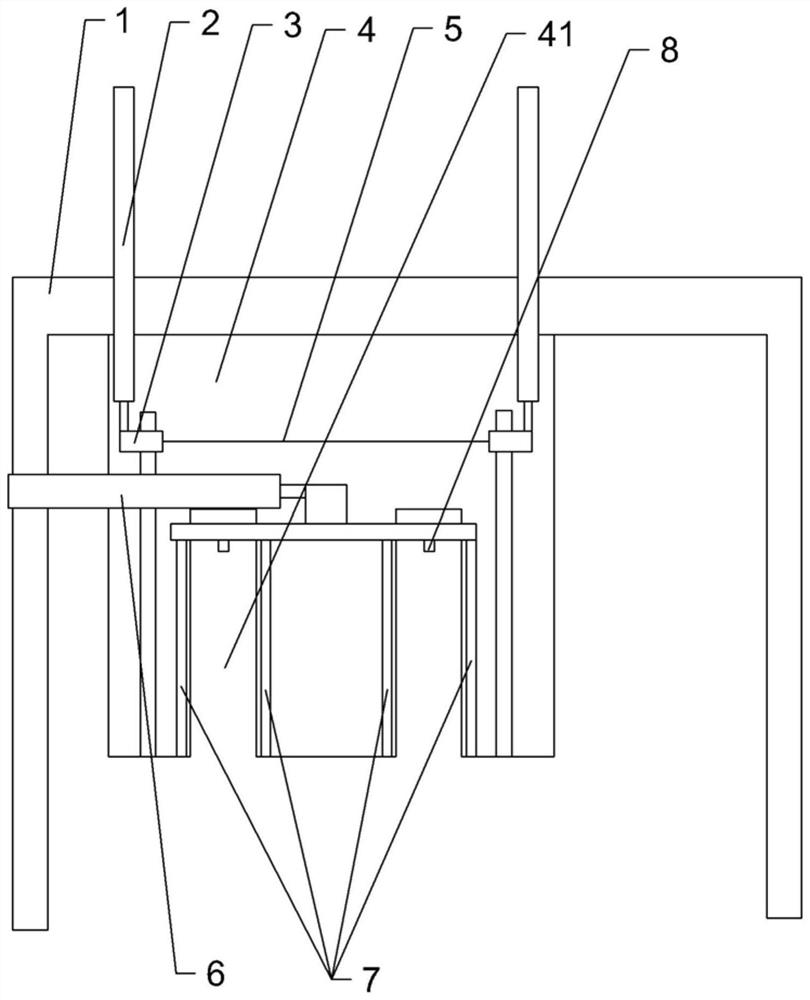

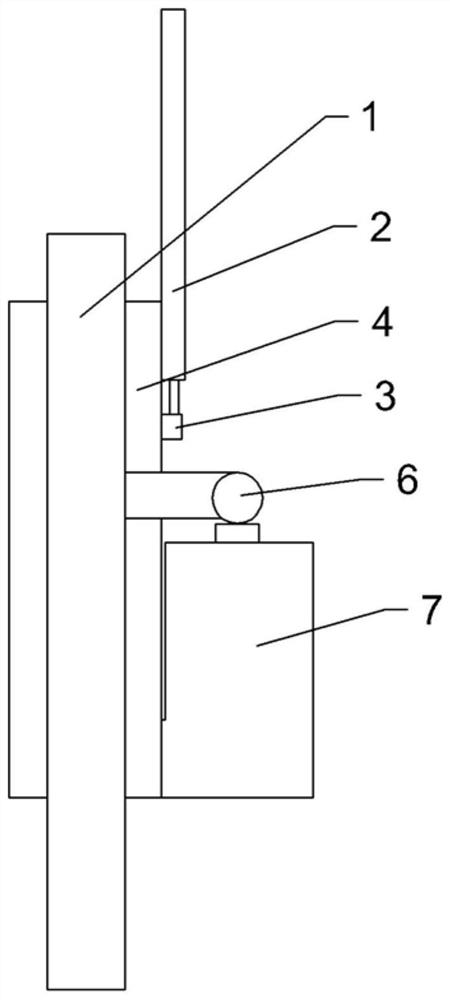

[0020] Embodiment one: if figure 1 with figure 2 Shown: a bottle body expansion detection device, including a bracket 1, a vertical block 4 is connected to the bracket 1 along the horizontal sliding, the block 4 is provided with a detection groove 41 that runs through the block 4 in the horizontal direction, and the detection groove 41 The transverse penetration direction of the block 4 is perpendicular to the sliding direction of the block 4 , and the detection slot 41 vertically penetrates the bottom of the block 4 . Two detection slots 41 are provided, and the two detection slots 41 are arranged side by side along the sliding direction of the block 4 . Two sliders 3 are vertically slidably connected on the clamping block 4, and the two sliders 3 are respectively located on both sides of the detection groove 41, and a stay rope 5 is connected between the two sliders 3; the two ends of the stay rope 5 respectively pass through Extension spring is connected with slide block...

Embodiment 2

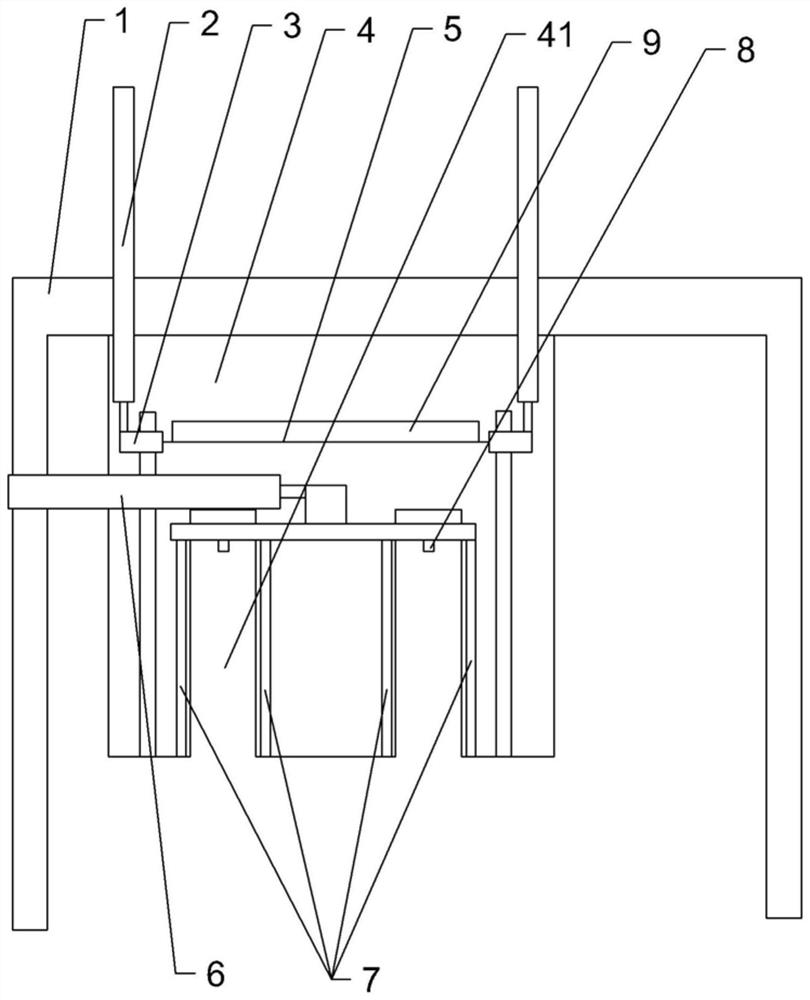

[0023] Embodiment two: the difference with embodiment one is only: as image 3 As shown, the pull cord 5 is preferably a cotton rope, and the upper part of the block 4 is bonded with a dye block 9 that is clutched and matched with the pull cord 5 . The stay cord 5 is set as a cotton rope, which is convenient for the cotton rope to dip into the dye on the dye block 9, so that the stay cord 5 will leave traces on the bottle body when it touches the bottle body inflated, and the position where the traces are left It is basically located directly above the position of the swelling defect of the bottle body, thus forming the effect of marking the swelling defect, and then analyzing the swelling defect of the bottle body through the traces left by the drawstring 5 on the bottle body, which is convenient for later guidance Improve the process equipment in the bottle body forming stage, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com