Multi-steel-ingot row one-time casting molding device

A casting molding, one-time technology, applied in ingot workshops, foundry workshops, casting equipment, etc., can solve the problems of low production efficiency, difficulty in picking up parts in the later stage, poor molding quality, etc., and achieve high production efficiency and good practical use value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

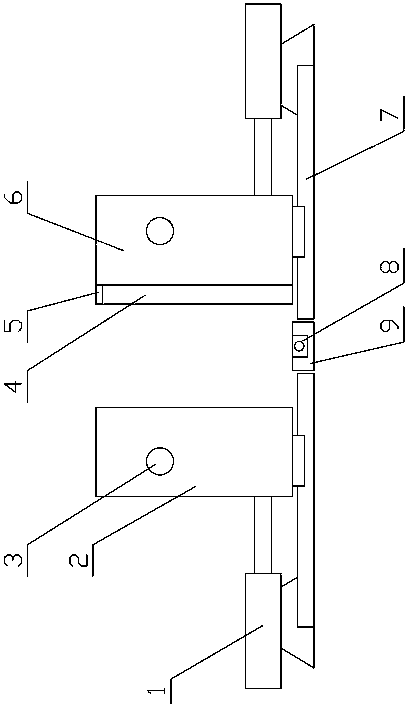

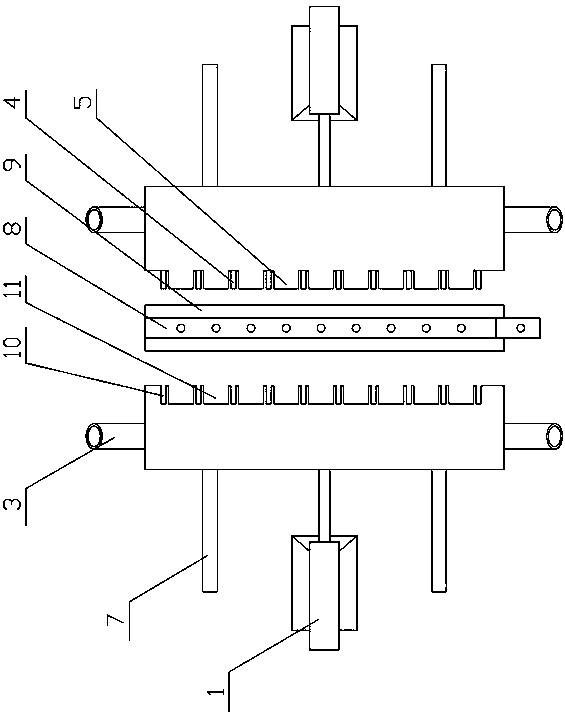

[0011] see figure 1 , figure 2 , the present invention is a multi-steel ingot row one-time casting molding device, which has slide rails 7 symmetrically arranged on the left and right sides, and the left casting mold 2 and the right casting mold 6 are slidably connected to the slide rails on the left and right sides, respectively, and the left casting mold and the The right casting molds are relatively arranged and their respective bottoms slide on the corresponding slide rails. The left casting mold and the right casting mold are respectively driven forward or backward by a propulsion cylinder 1; the inner side walls of the left casting molds are evenly spaced into Several steel ingot casting cavities 11 are arranged in a row, and both sides of each steel ingot casting cavity are provided with grooves 10 arranged from top to bottom. The bump 4 corresponding to the groove on the left casting mold, when the left casting mold and the right casting mold are closed, the bump and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com