A steel belt drive mechanism and exposure platform for optical inspection of materials outside the cabin

A driving mechanism and steel belt technology, which is applied in the analysis of materials, motor vehicles, scientific instruments, etc., can solve the problems that the driving mechanism cannot adapt to the space environment, and the safety and reliability cannot meet the requirements of the space station, so as to achieve strong environmental adaptability and safety The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

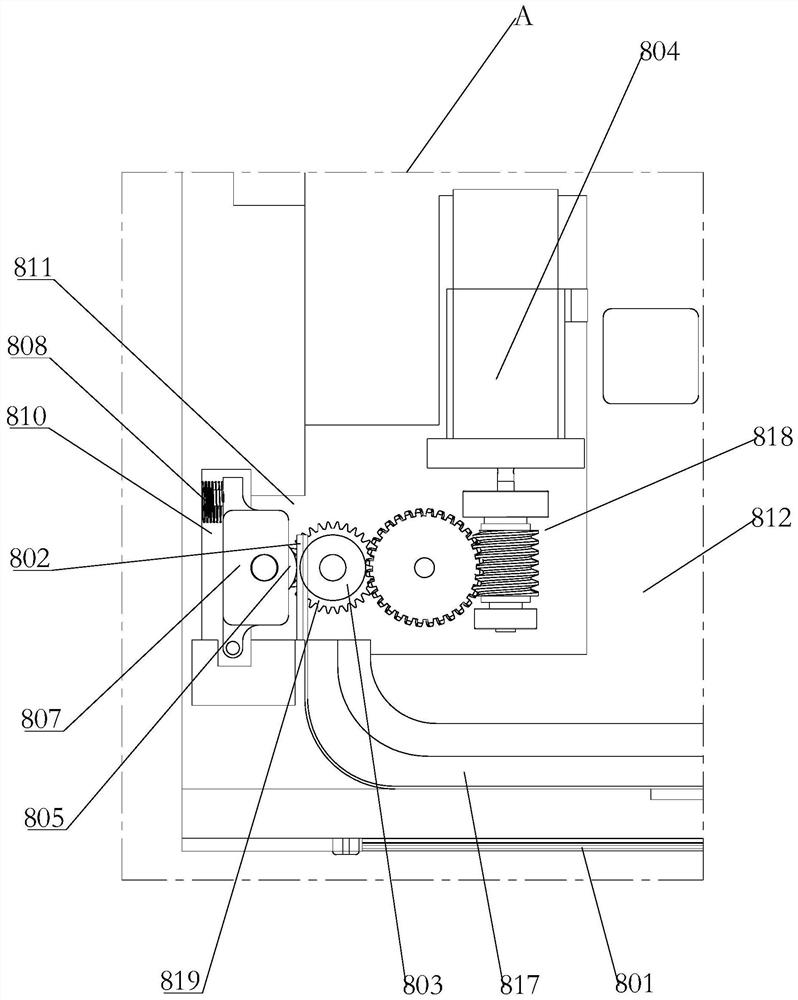

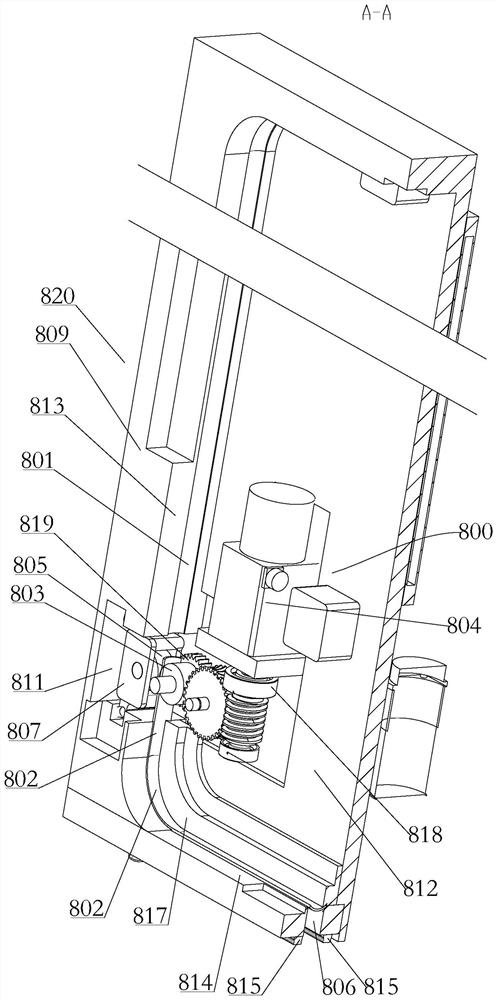

[0058] Such as Figure 1-Figure 4 As shown, a steel belt drive mechanism 800 for optical inspection of materials outside the cabin in this embodiment includes:

[0059] The track 801 for the steel belt 802 to move; the steel belt is the transmission actuator, which utilizes the steel belt's own rigidity to drive the steel belt to reciprocate linearly in a limited space under the drive of the steel belt friction wheel;

[0060] The driving friction wheel 803 is connected with the driving device 804 and rotates under the driving of the driving device 804; the driving device 804 can be selected from a driving motor; the driving friction wheel is a steel belt clamping device, which forms a normal direction on the steel belt by clamping Compression force, providing support for friction drive;

[0061] The driving friction wheel 805 is arranged side by side with the driving friction wheel 803 and is located on both sides of the track 801 respectively, and the steel belt 802 is inte...

Embodiment 2

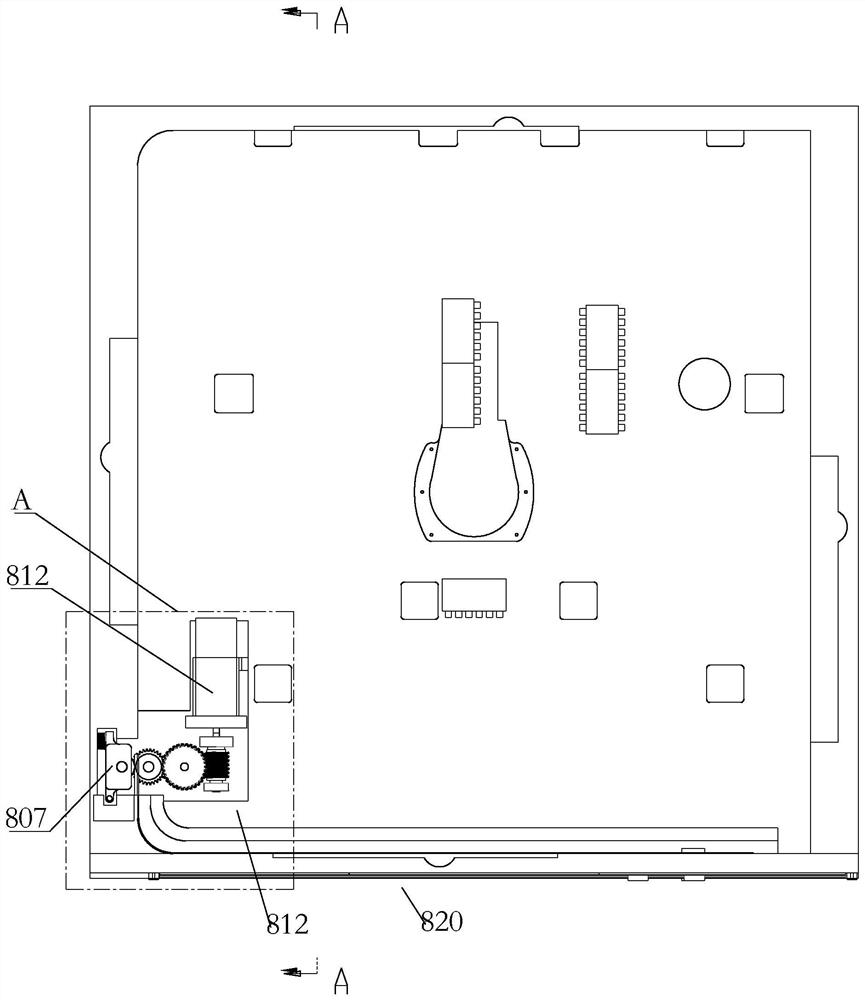

[0079] A material outdoor exposure platform in this embodiment includes a test box, an optical inspection device, an installation platform 820 and the steel belt drive mechanism 800, the test box is installed on the installation platform 820, and the The exposed surface of the test box after opening is arranged towards the surroundings of the installation platform 820, the track 801 is arranged at a position close to the peripheral side of the installation platform 820, and the optical inspection device is driven by the steel belt 802 to surround the The peripheral side of the installation platform 820 reciprocates to inspect the exposed surface.

[0080] Among them, such as Figure 1-Figure 4 As shown, the installation platform 820 is in a square shape, and the rail 801 is located inside two adjacent sides of the installation platform 820 .

[0081] The exposed platform of this embodiment adopts the steel belt to drive the optical inspection device to reciprocate around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com