Mounting structure of fabricated lamp trough decorative line

A technology of decorative lines and installation structures, which is applied to building components, building structures, buildings, etc., can solve the problems of cumbersome production, sagging of plates, and difficult quality control of degraded light troughs, so as to achieve simple construction process, solve material waste, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

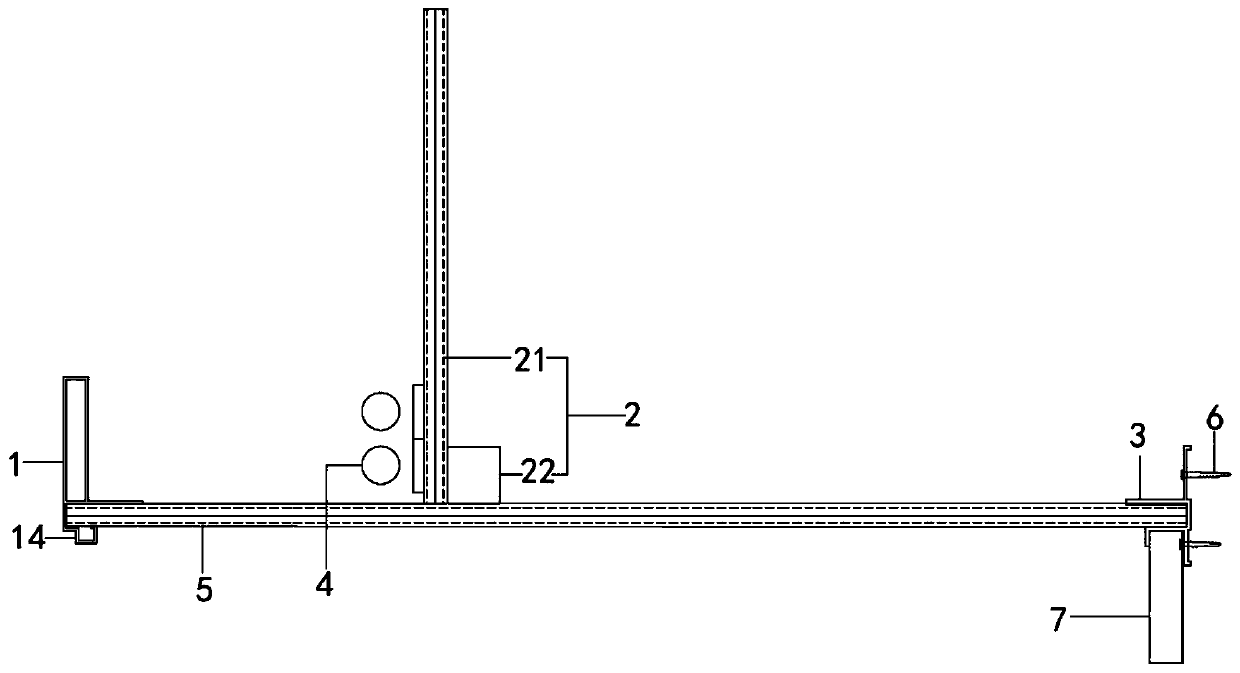

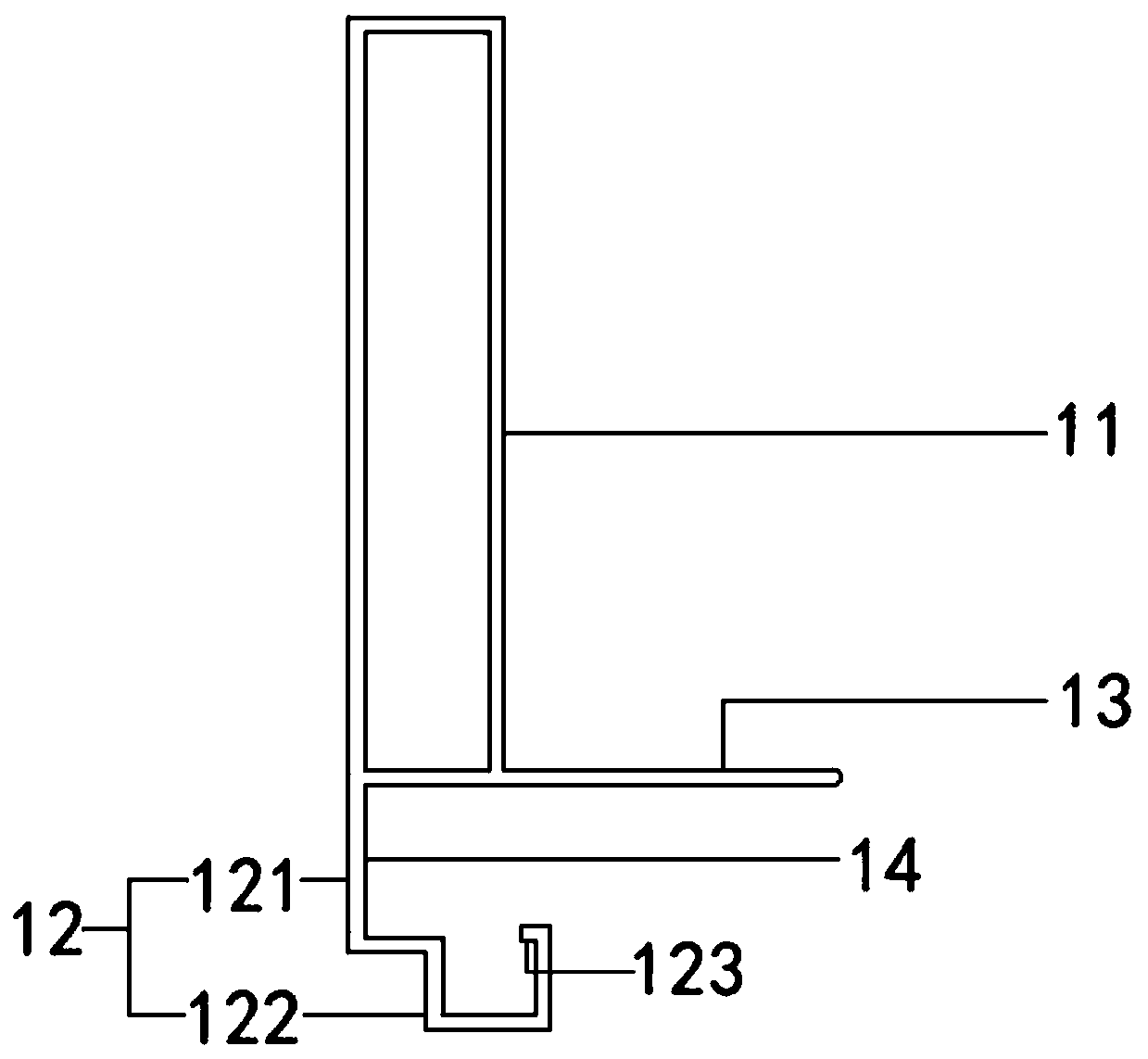

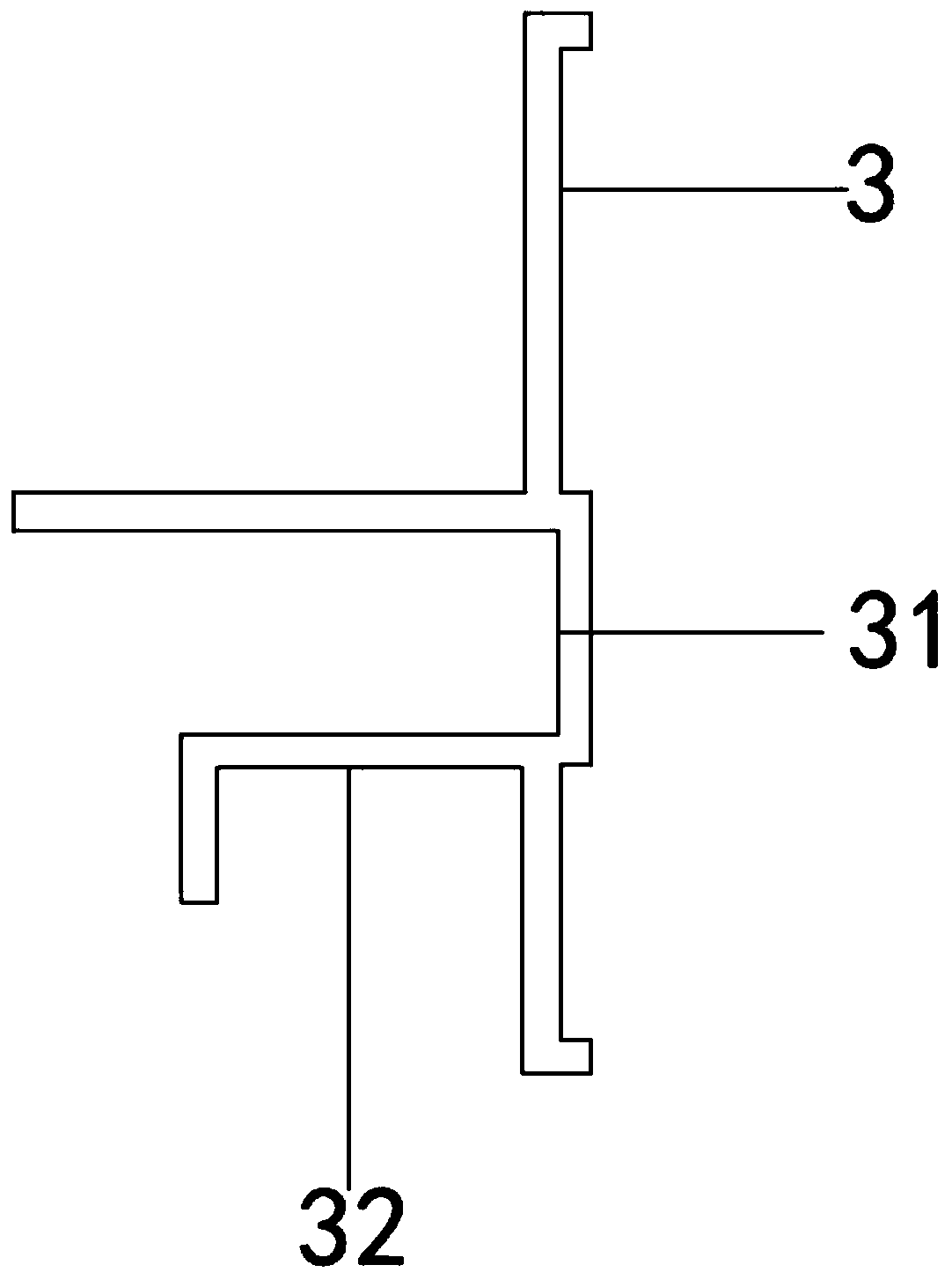

[0027] See Figure 1 to Figure 3 , The figure shows a mounting structure of the assembly-type lamp trough moldings according to an embodiment of the present invention, which mainly includes a light trough molding 1, a first fixing member 2 and a second fixing member 3. The first fixing member 2 includes The first connecting plate 21 and the second connecting plate 22, the first connecting plate 21 is fixedly connected with at least one light strip 4, the bottom of the first connecting plate 21 is connected to the second connecting plate 22, and the bottom of the second connecting plate 22 is fixedly connected There is a first decorative panel 5, one end of the first decorative panel 5 is connected to the second fixing member 3, and the other end of the first decorative panel 5 is connected to the light trough molding 1. The light trough molding 1 includes a first decorative plate 11 and The second decorative board 12, the second decorative board 12 is fixedly connected to the b...

Embodiment 2

[0036] See Figure 1 to Figure 3 , The figure shows a mounting structure of a fabricated lamp trough decorative line provided by the second embodiment of the present invention. On the basis of the foregoing embodiments, this embodiment further makes the following as an improved technical solution: A third decorative board 13 extends horizontally at the bottom of a decorative board 11, the third decorative board 13 abuts the first decorative board 5, and the first decorative board 11, the second decorative board 12 and the third decorative board 13 are integrally formed.

[0037] Through the arrangement of the above structure, the third decorative panel extends out of the first decorative panel and contacts the top of the first decorative panel, which can increase the contact area between the first decorative panel and the third decorative panel, and achieve the effect of improving the friction between the two , And then achieve the purpose of improving the quality of installation...

Embodiment 3

[0039] See Figure 1 to Figure 3 , The figure shows a mounting structure of a fabricated lamp trough decorative line provided by the third embodiment of the present invention. This embodiment further makes the following as an improved technical solution on the basis of the foregoing embodiments: The second decorative board 12 includes an L-shaped decorative board 121 and a “mouth”-shaped decorative board 122. The “mouth”-shaped decorative board 122 is vertically connected to the bottom of the L-shaped decorative board 121. The right side of the “mouth”-shaped decorative board 122 is higher than the left side. A baffle 123 extends on the right side of the “mouth”-shaped decorative board 122. In this way, after the first decorative panel is glued and bonded in the slot, after the glue is cured, since the height of the right side of the mouth-shaped decorative panel is higher than the left, the right side extends with a baffle, which forms a clamping structure with the cured glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com